|

|

|

<Qt>

dr.Godfried-Willem

RAES

Ghislain

& Dierik POTVLIEGHE

Johannes

TAELMAN

Kristof

LAUWERS

2005 -

2008

onderzoeksprojekt

rond de ontwikkeling van nieuwe expressiemiddelen van de School of

Arts, Hogeschool Gent

|

Quartertone organ module: <Qt>

The research and development of this instrument building project is an intensive

collaboration in the realms of artistic research under the auspices of the University

College Ghent (Hogent), department of music and the Logos Foundation. On the

practical level, this organ is the result of an intensive collaborative effort

by Ghislain Potvlieghe (specialist in historic organ building) and dr.Godfried-Willem

Raes. The development of the PIC firmware in assembly language used to control

this robotic organ is in the hands of Johannes Taelman. Research into practical

and historical repertoire for such a novel quartertone instrument, was done

by Sebastian Bradt (Hogeschool Gent). The driver software developped within

the GMT language was written by Kristof Lauwers (Logos Foundation).

The main purpose was to build a wide ambitus organ register tuned in equal

temperament quarter tones. The instrument should be capable of automatic playing,

controlled by computer software, as well as through a set of two conventional

keyboards. The whole instrument had to be easily transportable, dictating the

use of brass and or pure tin/antimony pipework instead of the traditional lead/tin

alloy. The range covers 6 full octaves (from midi note 36 to 108) . Wind pressure

modulation can be used to expressive purposes. Tremulant effects as well as

accented notes are a possibility. Subtle and individual touch velocity control

is implemented.

The pipes are constructed after the following early prototype, made of brass

and sounding midi note 77:

For the actual realisation, we decided to make use of an alloy composed of

95% tin and 5% antimony, leading to mechanically quite strong and leadfree pipework

that also will hold tuning very well. Experiments relative to the mechanical

strength of Sn-Pb soldered brass pipes have shown that these are pretty sensitive

to breaking under shock conditions. The heterogenity of the materials being

at the origin of this weakness. The picture below shows the labium and pipefeet

for the prototype pipes sounding notes 36 and 48.

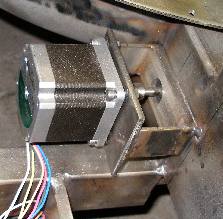

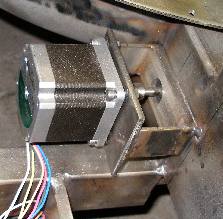

Qt is internally controlled by thirteen PIC processors. Twelve processors (PIC

18F4620-I/P) are used to control each set of 72 solenoids used to operate the

valves in the windchest, whereas the thirteenth PIC (18F2525-I/SP) steers the

compressor motor functions and the windpressure modulation. For the latter two

precize stepper motors are used to drive valves inside the conducts leading

to the upper and the lower windchest. We opted for the MicroChip PIC18F4620

because of its 64kByte flash program memory (good for 32768 single word instructions)

, 3986 bytes static RAM, 1024 bytes Eeprom and last but not least, its 36 available

I/O pins. With these specs it became possible to use a single chip to control

14 notes, since each note requires 2 I/O pins. The PIC 18F2525 follows the same

architecture but has only 25 I/O pins and 48kByte flash program memory. Enough

in any case for the requirements of motor control and feedback in this design.

The upperplate of the windchests under which the solenoid valves are mounted,

is made from very thick african obeche (or wawa) wood. This wood is very good

for wood cutting and carving, an essential feature since we had to bring the

wood to an exact and airtight matching with the curved metal work, using chivels.

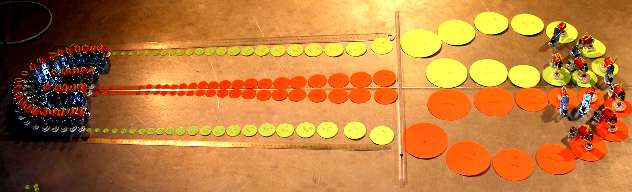

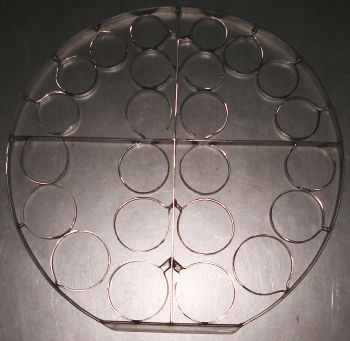

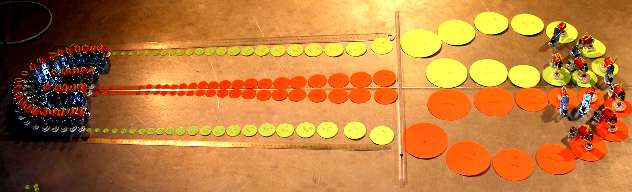

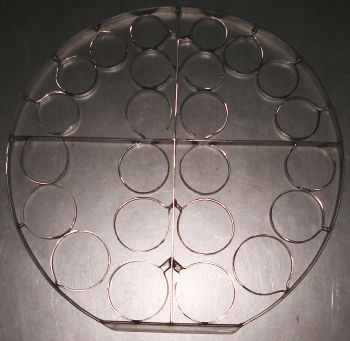

The arrangement of the lowest octave of the pipes on the lower windchest is

as follows: The

pipes 47 and 47.5 are in the very front of the instrument. The arrangement for

the high windchest is:

The

pipes 47 and 47.5 are in the very front of the instrument. The arrangement for

the high windchest is:  The notes are numbered in fractional midi, note number 60 corresponding to middle

C on the piano keyboard.

The notes are numbered in fractional midi, note number 60 corresponding to middle

C on the piano keyboard.

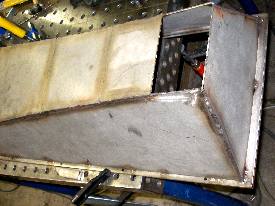

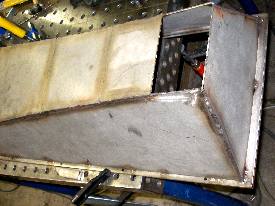

The entire Qt module is mounted on 4 large wheels and thus is, although pretty

heavy (ca.220kg) , also very transportable. All metal work for the two windchests

and the entire chassis was realized using the TIG welding process (manual) on

AISI 304L stainless steel.

- Design, research & construction: Dr.Godfried-Willem Raes

- Pipe work: Ghislain Potvlieghe

- Tuning and intonation: Dierik Potvlieghe

- PIC microcoding: Johannes Taelman

- Software integration in composition software: Kristof Lauwers

- Collaborators: Sebastian Bradt, Kris De Baerdemacker, Hans Roels, Moniek

Darge, Xavier Verhelst.

Technical specifications:

sizes: length: 2000mm, width: 700mm, height: 1760mm.

power: 230V - 950Watt (peak)

weight: 226kg

Control: midi protocol, using 2 channels. Note ON/OFF with velocity implemented.

Volume controller (7) used for wind pressure. Controllers nr. 1 and 2 for wind

valve control and tremulant effects. Other controllers may be added later. Direct

control via UDP/IP network is under development.

Wiring overview:

Electronic circuitry:

For <Qt> either the use of pallet valves or conical valves in the windchest

were first under investigation. We were after a maximum touch sensitivity for

this organ, such as to make it sound like an ancient mechanical organ positive,

where the player can in fact control a little bit the onset of the pipe sounds

by modification of the speed wherewith the keys are depressed. Conical valves,

in combination with softshift solenoids do indeed work extremely well to this

end. (cfr..the use of a single conical valve in our automated

saxophone). However, each valve has to be made on the lathe and the cones

have to match perfectly well with the conical holes in the windchest upper plate

itself. Not an easy matter, particularly since wood was proven to be unsuitable.

A massive upperplate from metal was investigated but rejected due to the extraordinary

weight it would add to an instrument that was meant to be transportable. Synthetic

materials such as glassfiber reinforced epoxy were tried, but are not commercially

available in the sizes we needed. Thus we decided to go back to our well known

pallet valves. They can be seen on the picture showing the internal view of

the upper windchest (notes 48-108). To get a better sensitivity to velocity, we modified the spring tension. Normally

a spring is used to keep the valves just closed at rest. So the force is just

a bit larger than the downwards force excerted by the weigth of the valves,

since they are mounted upside down. By increasing this force above this minimum

required for keeping them closed at rest, the valves gain a more gradual opening

traject, at the detriment however of some response speed. The circuit we developed

for achieving a bit of velocity sensitivity from these solenoid operated valves

looks like this:

To get a better sensitivity to velocity, we modified the spring tension. Normally

a spring is used to keep the valves just closed at rest. So the force is just

a bit larger than the downwards force excerted by the weigth of the valves,

since they are mounted upside down. By increasing this force above this minimum

required for keeping them closed at rest, the valves gain a more gradual opening

traject, at the detriment however of some response speed. The circuit we developed

for achieving a bit of velocity sensitivity from these solenoid operated valves

looks like this:

This circuit is a further development of the circuits we used in the design

of our <player pianos> and <Harma>.

The PNP transistor we used in these earlier designs is here replaced with a

p-channel mosfet (BS250 or similar type). The gate goes directly to ground and

the zenerdiode, essential in the bipolar design, could be left out. In this

new design the negative pulse driver mosfet has to be a logic level type, identical

to the hold-driver mosfet. Note that, due to the gate capacitance of the negative

pulse mosfet (ca. 1.5nF), there is a inherent timeconstant in the order of 7

microseconds. Since the PIC's minimum pulse duration is 19.2 microseconds, this

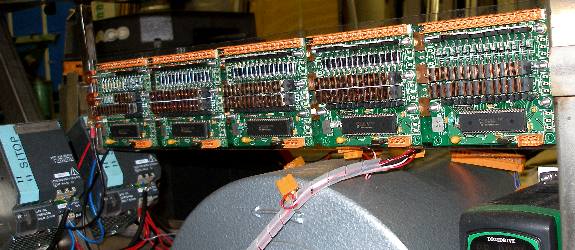

does not lead to a performance penalty. A single PIC controller (Microchip PIC

18F4620 - I/P) can steer 14 notes. For the low windchest we thus use two boards,

leaving four outputs unused for notes (they can be used for light effects).

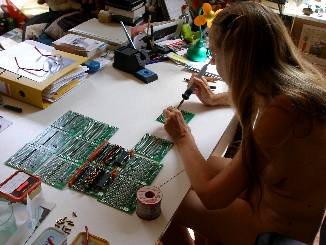

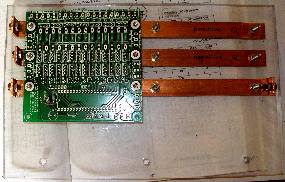

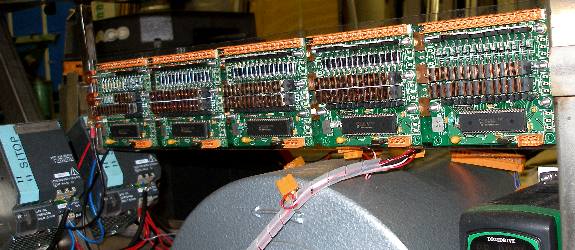

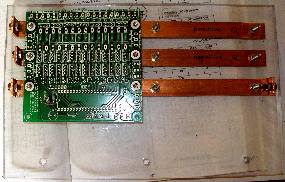

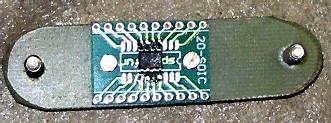

For the high windchest, ten boards in total. The prototype PC board looks like:

It was developed

in Eagle software for PCB design and produced from the datafiles at Eurocircuits

in Hungary. (Plot & Go). The first batch had a wiring bug, repaired in our

second (gold layered) production batch.

It was developed

in Eagle software for PCB design and produced from the datafiles at Eurocircuits

in Hungary. (Plot & Go). The first batch had a wiring bug, repaired in our

second (gold layered) production batch.

The midi input board is designed after the following schematics:

Here we have merely the compulsary optocoupler input with reverse polarity

protection diode. The selection of resistors around the optocoupler is quite

critical if you want to achieve optimum speed and no data loss even with midi

back-to-back data streams. In the practical realisation we substituted the 6N138

type originally specified, by a 6N137, leading to a fivefold improvement in

speed. Next the inverted output signal, on TTL levels, is fed to 10 inverter

buffers which will drive the many note valve steering boards:

To allow users easy star-like connections to many more robots and automats,

we provided this circuit also with no less then 5 real midi-thru drivers and

corresponding 5pole din connectors:

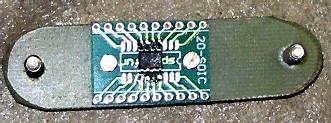

Still on the very same PC board, we found place for a PIC microcontroller to

be used for the control of the motor functions, lights, tremulant and other

optional effects:

The board offers buffering for the midi signals to be fed into the very many

pulse/hold driver boards as well as a single PIC controller (PIC18F2525-I/SP)

, in charge of wind control for the radial compressor. Extra bit outputs are

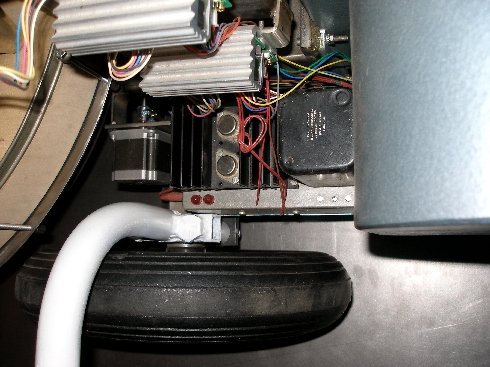

provided for the expression control: two stepping motor driven tremulants etc.

Two pins are configured as inputs and used to read the output of the MLX90316

Hall Effect based rotary position sensor IC's. These are mounted on the axis

of the wind valves.

At last, almost as a reminder, however an essential one, DC voltage buffering

and decoupling with ample 100nF caps has been foreseen in the design:

The actual external wiring for this PC board looks like:

The specifications of the pallet solenoids used in the windchest are: 12/14

V dc, 75 Ohm resistance, 190 mA current. The Laukhuff order numbers are given

in the list of materials at the end of this

document. Cost: 3800 Euro. The original springs in the valves (0.4 x 3.4 x 26)

were replaced by custom made stronger types by us (0.5 x 4.5 x 25) , this to

allow for note aftertouch control.

The windvalves in the lower and upper windchest can be used both as windpressure

expression controls and as tremulants. These valves are controlled by stepping

motors and controllers wired after this schematic:

If we take the static windpressure in the windchest as 150 mm H2O

(15 mB, 1.5 kPa or 1500 N/m2), then the worst case static force on the windvalves

(100 mmx150 mm = 1.5 dm2 in surface) is 22.5 Newton. This force however only

applies if the other side of the valve is fully opened.. Such circumstances

could only exist under full cluster conditions, where the wind pressure will

collapse anyway. Under normal conditions, the pressure difference between both

sides of the valves will be limited to ca. 5%. In addition to this consideration

it must be noted that in our design, very much on purpose, the valves do leak.

Otherwize, they would fully interrupt the tones produced rather than cause a

smoorth amplitude (and a bit of frequency-) modulation. So the stepper motor

we selected should under all normal circumstances be powerfull enough to rotate

this valve. The manufacturer gives following force curves for the given (Sanyo)

controller and stepping motor combination:

Since the current through the motor winding will fall back to 50% of the normal

current within 200 ms after the last pulse on cw or cww is received by the controller,

the slowest possible tremulant frequency will be ca. 0.06 Hz. The pulsing frequency

would than be 6 Hz. This is also the slowest possible fluent speed of any valve

movements. The pulse timing requirements and constraints are summarized in the

graph below:

The specifications for the motor and compressor are:

- Nominal pressure: 120 mmH20 (12 mBar) - 8 m3/min

- Year of construction: april 2006 - nr. 29790

- Motor data: 0.45 HP, 230/400 V - 1.5/0.9 A , 2800 rpm @ 50Hz

- Cost: 1850 Euro

Note that the operational pressure is higher. Qt was intonated and tuned on

a pressure of 140 mmH20 (14 mBar).

MIDI-Implementation table for <Qt>

| Midi command |

status byte |

byte1 |

byte 2 |

remarks |

| Note Off |

128 + 5 |

note (36-108) |

0 |

release not implemented |

| |

128 + 6 |

note(36-107) |

0 |

release not implemented |

| Note On |

144 + 5 |

note (36-108) |

velocity |

velo=0 = note off |

| |

144 + 5 |

note (36-107) |

velocity |

velo=0 = note off |

| Key pressure |

160 + 5 |

note (36-108) |

note pressure |

only if ctrl.69 is ON |

| |

160 + 6 |

note (36-107) |

note pressure |

only if ctrl 69 is ON |

| Program Change |

192 + 5 |

velo lookup selection

122 = default

120-127: tables

|

- |

look ups are sysex programmable |

| |

192 + 6 |

velo lookup selection, as above |

- |

look ups are sysex programmable |

| Controller |

176 + 5 or + 6 |

1 |

low windvalve position |

0= closed, 127 = opened |

| |

176 + 5 or + 6 |

2 |

high windvalve position |

0 = closed, 127 = opened |

| |

176 + 5 or + 6 |

7 |

wind pressure motor |

normal value = 102 |

| |

176 + 5 or + 6 |

8 |

light strenght |

blue LED spotlites |

| |

176 + 5 or + 6 |

11 |

low tremulant speed |

normal value = 96 |

| |

176 + 5 or + 6 |

12 |

high tremulant speed |

normal value = 96 |

| |

176 + 5 or + 6 |

66 |

0 or not 0 |

wind motor on off switch |

| |

176 + 5 or + 6 |

67 |

0 or not 0 |

low valve motor power off |

| |

176 + 5 or + 6 |

68 |

0 or not 0 |

high valve motor power off |

| |

176 + 5 or + 6 |

69 |

0 or not 0 |

enable/ disable poly aftertouch |

| |

176 +5 or + 6 |

70 |

0 or not 0 |

enable/disable hold (stacc. mode) |

| |

176 + 5 or + 6 |

123 |

0 |

all notes off |

| Channel aftertouch |

208 + 5 |

low windvalve position |

- |

same as ctrl 1 |

| |

208 + 6 |

high windvalve position |

- |

same as ctrl 2 |

| Lights: |

144 + 5 |

35 |

0 or not 0 |

lights lower windchest K-side |

| |

144 + 6 |

35 |

0 or not 0 |

lights lower windchest Q-side |

| |

144 + 5 |

110 |

0 or not 0 |

light tail upper windchest |

| |

144 + 5 |

111 |

0 or not 0 |

light Kside upper windchest |

| |

144 + 6 |

111 |

0 or nor 0 |

light Q side upper windchest |

| |

144 + 5 or +6 |

120 |

0 or not 0 |

light BIM box 5V supply |

| SysEx |

|

|

|

to be documented later |

| |

|

|

|

used to program different velo scalings |

Music composed for <Qt>:

- Godfried-Willem Raes "Qt-Split", for Picradar interfaces and two

nude performers

- Thomas Smetryns "Und der Dichter spricht, spricht der Dichter"

- Yvan Vander Sanden

- Frank Nuyts: "Two Quartertone pieces don't make a half one"

- Godfried-Willem Raes "Gestro Qt"

- Godfried-Willem Raes "Qua Qt", quadrada study #12 for Qt.

- Wouter Simoens "Kompositie voor een kwarttonen orgel"

- Sebastian Bradt "Taxidermie", for Qt

- Barbara Buchowiec "Mars of the liliqts" for Qt and viola

- Godfried-Willem Raes "Wouwel"

for Qt.

Recording

Recording

- Godfried-Willem Raes "Qtree" for Qt

- Godfried-Willem Raes "Akafest" for Qt

- Karel Miry "De Vlaamse Leeuw" (quartertone version)

Recording

Recording

- Hans Roels

- Kristof Lauwers

- Kris De Baerdemacker "voor qt en orgel"

- Judy Dunaway "Duo for Qt and balloon"

- Pieter Corten

- Jelle Proost

- Gamut Inc. 'Zeroth Law'

- Benjamien Lycke "Bagatelle pour Qt" (2010)

Recording

Recording

Nederlands:

Kwarttoons orgel : <Qt>

Qt is de roepnaam van een postdoktoraal experimenteel artistiek onderzoeksprojekt,

officieel gestart op 1 oktober 2005, onder de auspicien van Hogeschool Gent

in samenwerking met Stichting Logos. De wetenschappelijke ondersteuning en praktische

leiding was in handen van dr.Godfried-Willlem Raes, docent kompositie, akoestiek,

klankonderzoek en onderzoeksmetodiek aan het departement muziek en drama. Dit

geautomatiseerd orgel kwam praktisch tot stand als een samenwerkingsprojekt

van Ghislain Potvlieghe (specialist historische orgelbouw), Dierik Potvlieghe

(orgelbouwer), Johannes Taelman (ontwikkeling en research inzake mikrokontrollers

voor de besturing), Sebastian Bradt (onderzoek naar aktueel en historisch repertoire

op het gebied van de kwarttoonsmuziek en komponist van nieuwe muziek voor deze

automaat), Kristof Lauwers (ontwikkeling aansturingssoftware ten behoeve van

komponisten) en dr.Godfried-Willem Raes.

Het opzet bestond erin een zuiver getemperd kwarttoonsinstrument te bouwen

met een grote tessituur: minstens 6 oktaven (midi 36 - 108).  Verder

gaat het in dit ontwerp om een zuiver akoestisch instrument, met pijpen dus.

De luchtdruk is ten dienste van de expressieve mogelijkheden op dynamisch vlak

goed en snel moduleerbaar, terwijl ook aksenten en tremulant mogelijk zijn.

De tremulant werd in twee onafhankelijke systemen uitgevoerd, waardoor de bas

een andere tremulant frekwentie kan krijgen als de diskant. De akoestisch opgebrachte

geluidsdruk diende bij dit ontwerp voldoende groot te zijn om in een orkestrale

onversterkte bezetting probleemloos te kunnen worden ingezet. Bovendien diende

de stemming zo vast te zijn, dat regelmatig bijstemmen van het instrument niet

nodig zou zijn. Daarom gingen we bij het ontwerp uit van aan de bovenkant dichtgesoldeerde

pijpen. Transportbestendigheid en verplaatsbaarheid waren een belangrijke eis.

Deze eis sluit bij voorbaat het gebruik van klassieke legeringen voor orgelpijpen

(60% tin, 40% lood in het beste geval) uit. Deze zakken immers bij blootstelling

aan trillingen, onvermijdelijk bij verplaatsingen, door onder de druk van hun

eigen gewicht. Ook louter ekologische (en sedert kort ook Europees wettelijke)

overwegingen pleiten trouwens tegen het gebruik van lood. Proeven werden gedaan

met messing enerzijds en legeringen bestaande uit 95% tin en 5% antimoon anderzijds.

De met Sn-Pb gesoldeerde messingpijpen bleken erg gevoelig aan breuk op de soldeernaden.

(cfr. <Puff>). Hardsolderen of brazeren ware ook

mogelijk, maar technisch erg lastig uitvoerbaar gezien de vereiste precizie.

Lassen van messing, de meest superieure techniek, bleek -althans voor ons- zo

goed als ondoenbaar omwille van de onstabiliteit van de legering (het zink oxydeert

namelijk). Uiteindelijk opteerden we dan maar voor de volledig loodvrije pijpen

uit tin en antimoon, een legering waarmee ook traditionele orgelbouwers goed

overweg kunnen. Omwille van de gewenste hardheid, opteerden we in ultimo nog

voor de toevoeging van 1% koper in de legering: 95% tin, 4% antimoon, 1% koper

werd het dus uiteindelijk.

Verder

gaat het in dit ontwerp om een zuiver akoestisch instrument, met pijpen dus.

De luchtdruk is ten dienste van de expressieve mogelijkheden op dynamisch vlak

goed en snel moduleerbaar, terwijl ook aksenten en tremulant mogelijk zijn.

De tremulant werd in twee onafhankelijke systemen uitgevoerd, waardoor de bas

een andere tremulant frekwentie kan krijgen als de diskant. De akoestisch opgebrachte

geluidsdruk diende bij dit ontwerp voldoende groot te zijn om in een orkestrale

onversterkte bezetting probleemloos te kunnen worden ingezet. Bovendien diende

de stemming zo vast te zijn, dat regelmatig bijstemmen van het instrument niet

nodig zou zijn. Daarom gingen we bij het ontwerp uit van aan de bovenkant dichtgesoldeerde

pijpen. Transportbestendigheid en verplaatsbaarheid waren een belangrijke eis.

Deze eis sluit bij voorbaat het gebruik van klassieke legeringen voor orgelpijpen

(60% tin, 40% lood in het beste geval) uit. Deze zakken immers bij blootstelling

aan trillingen, onvermijdelijk bij verplaatsingen, door onder de druk van hun

eigen gewicht. Ook louter ekologische (en sedert kort ook Europees wettelijke)

overwegingen pleiten trouwens tegen het gebruik van lood. Proeven werden gedaan

met messing enerzijds en legeringen bestaande uit 95% tin en 5% antimoon anderzijds.

De met Sn-Pb gesoldeerde messingpijpen bleken erg gevoelig aan breuk op de soldeernaden.

(cfr. <Puff>). Hardsolderen of brazeren ware ook

mogelijk, maar technisch erg lastig uitvoerbaar gezien de vereiste precizie.

Lassen van messing, de meest superieure techniek, bleek -althans voor ons- zo

goed als ondoenbaar omwille van de onstabiliteit van de legering (het zink oxydeert

namelijk). Uiteindelijk opteerden we dan maar voor de volledig loodvrije pijpen

uit tin en antimoon, een legering waarmee ook traditionele orgelbouwers goed

overweg kunnen. Omwille van de gewenste hardheid, opteerden we in ultimo nog

voor de toevoeging van 1% koper in de legering: 95% tin, 4% antimoon, 1% koper

werd het dus uiteindelijk.

Omwille van de gewenste mobiliteit van het instrument, werd het integraal op

goed stuurbare grote wielen met massief rubberen banden gemonteerd en werden

de afmetingen toch zo kompakt mogelijk gehouden. Deze voorwaarde dikteerde welhaast

automatisch het gebruik van gedekte pijpen evenals een betrekkelijk hoge winddruk

(100 tot 150 mm waterkolom, of 10 tot 15 mBar).

Het chassis en alle metalen delen voor de beide windladen en de kondukten werd

uitgevoerd in minstens 3 mm dik roestvast staal AISI304L en AISI316 onder gebruikmaking

van het volledig manuele TIG lasproces. Als toevoegmateriaal bij het lassen

werd uitsluitend AISI316 gebruikt. Het snijwerk werd uitgevoerd met een hoogfrekwent

plasma brander. Voor de afwerking werd volstaan met een grove borsteling met

een inox komstaalborstel. Aan de binnenzijde werden alle lasnaden, omwille van

het beperken van ongewenste turbulenties in de windstroom, zorgvuldig gladgeslepen.

Gezien deze opties in materiaalkeuze, moet het instrument kwa duurzaamheid zeker

aan alle stelbare eisen kunnen voldoen.

De volledige MIDI-implementatie, ten behoeve van eenvoudige gebruikers, publiceerden

we aan het eind van de engelse tekst hierboven. Deze implementatie maakt ook

een manuele bespeling via twee elektronische midi-keyboards eenvoudig mogelijk.

Voor het speelkomfort is het wel aangewezen keyboards te gebruiken met een tessituur

van zes oktaven en met individuele touch sensitivity. De beide keyboards worden

via een midi-merger rechtstreeks op <Qt> aangesloten. Een rechtstreekse

netwerkbesturing onder gebruikmaking van UDP/IP is eveneens voorzien. Dit is

vele malen superieur aan Midi, maar in gebruik alleen weggelegd voor technologisch

onderlegde komponisten en musici. Voor wie met hetzij PD hetzij GMT overweg

kan, is dit het aanbevolen besturingssysteem.

Gedetailleerde berekeningen van de mensuren en dimensionering voor

de bouw van het Qt register:

Eerste proef, berekening op grond van proefpijp uit messingbuis. Mensurering

rekening houdend met handelsdiameters en korresponderende materiaaldiktes van

bestaande messing buis.

link to look up table - naar overzichttabel

link to look up table - naar overzichttabel

Tweede proef, berekening op grond van proefpijpen gesoldeerd uit een

legering 95% tin en 5% antimoon. De breedte van het labium werd hier bepaald

op grond van 1/4 van de omtrek van de cilindrische pijpen.

link to look up table - naar overzichttabel

link to look up table - naar overzichttabel

Derde proef, berekening op grond van 5 proefpijpen

(36,48,60,72,84) gesoldeerd uit een legering 95% tin en 5% antimoon. Winddruk

85mm H20. De breedte van het labium werd hier bepaald op grond van 1/4 van de

omtrek van de cilindrische pijpen. Alle pijpen krijgen hier een individueel

verschillende mensuur.

link to look up table - naar overzichttabel

link to look up table - naar overzichttabel

Berekend door dr.Godfried-Willem Raes op 13.03.2006 naar prototypes gebouwd

begin maart 2006. Het volledige register werd in elkaar gezet en gesoldeerd

door Ghislain Potvlieghe in diens atelier. De eerste verzameling pijpen (120)

was klaar op 22 mei 2006. Het kompleterende oktaaf 96-108 op 29.06.2006. De

stemming en intonering vonden plaats in verschillende werkfazen na de montage

van de pijpen op de afgewerkte windladen. (Oktober 2006- Maart 2007) De gebouwde

pijpen werden, na het stemmen (met dichtsolderen aan de bovenzijde) en intoneren

opnieuw exakt opgemeten en vergeleken met de berekeningen.

link

naar definitieve en samenvattende tabel van de mensurering voor Qt.

link

naar definitieve en samenvattende tabel van de mensurering voor Qt.

Bouw- en research dagboek:

- 15.08.2004: eerste tekeningen en berekeningen, uitgaande van het pijpwerk

van <Puff>

- 01.10.2004: Sebastian Bradt in dienst bij het departement muziek en drama

(Hogent) voor onderzoek rond mikrotonaliteit.

- 08.10.2004: bespreking konstruktie pijpwerk met Ghislain Potvlieghe

- 09.10.2004: eerste proefpijp (midi 60) gebouwd door Ghislain. Berekeningsprogramma

geschreven voor de mensurering van de Qt pijpen.

- 20.03.2005: Bespreking van de mogelijkheid de ontwikkeling van Qt als onderzoeksprojekt

voor te stellen, met Jan Rispens.

- 20.08.2005: Eerste ondertekening onderzoeksprojekt kontrakt tussen Hogent

en Logos.

- 01.09.2005: Werk- en overlegvergadering met Ghislain Potvlieghe. Inventarisatie

materialen.

- 03.10.2005: Eerste berekeningen windlade. Officiele start onderzoeksprojekt

Hogeschool Gent. Het projekt loopt over twee jaar en behelst een halftijdse

opdracht voor dr.Godfried-Willem Raes. (@70% weddeschaal..., ondanks kwalifikatie)

- 04.10.2005: Volgens de eerste berekeningen lijkt een gesplitste windlade

de beste oplossing.

- 05.10.2005: Plaatsing in een dubbele rij, eerder dan in rijen van 3 of 4

pijpen is voor de klankprojektie beter dan plaatsing in 3 of 4 rijen. De dubbele

rij organisatie kompromiteert evenwel sterk de transporteerbaarheid.

- 06.10.2005: Eerste tests voor de konstruktie van de elektromagnetische ventielen.

- 07.10.2005: Maximale repetitie-snelheid met een tegendruk van 12 mBar is

ca. 16Hz voor ventielen met een klepzitting van 23 mm en afdichting met kalfsleer

of het sintetisch equivalent, kalopel. Een Flatterzunge effekt is dus wel

haalbaar behalve wellicht op de grootste pijpen, waarvoor immers 35 mm grote

polsters moeten gebruikt worden.

Dit type is afgebeeld op de foto.

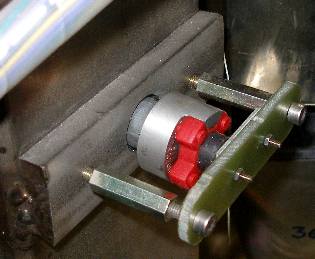

Dit type is afgebeeld op de foto.

- 11.10.2005: Konstruktie van een konisch testventiel voor evaluatie. Kegelventielen

laten principieel een soepele graduele drukregeling toe, maar reageren door

hun grotere massa alvast heel wat trager. Hun toepassing dikteert de toepassing

van tubular solenoids, zoals reeds eerder toegepast bij de bouw van onze player

piano's.

- 14.10.2005: Ontwikkeling software voor berekening van de dynamiek van de

pijpen in funktie van mensuur en winddruk. (PBCC compiler)

- 27.10.2005: research naar vermijding glitches in real time applicaties onder

Windows.

- 28.10.2005: bestudering mogelijkheid tot integratie van Qt in de orkestratie

van Workers Union van Louis Andriessen, een orkestratie uitgevoerd door Sebastian

Bradt.

- 01.11- 21.11.2005: Vedere proeven met kegelventielen en analoge besturing

daarvan. De eigenmassa van de kegels beperkt in hoge mate de repetitiesnelheid

en ook de responstijd van de ventielen. Proefkonstruktie gemaakt met uitgeholde

kegels, ter beperking van de eigenmassa. Dit is echter extreem arbeidsintensief.

Kegels blijken ook erg gevoelig aan vastklemmen, wat een erg hoge precisie

in het hoon- en polierwerk veronderstelt. De kegelventiel technologie blijkt

eerder geschikt voor automatische monofone blaasinstrumenten. De enorme kosten

wegen bij toepassing in orgels niet op tegen de voordelen.

- 25.11.2005: Labo tests met mini ventola blazers (5-7.5mBar) en Siemens M410

programmeerbare motor controllers voor fleksibele regelingen van de winddruk.

Een snelle regeling wordt beperkt door de inertie van de kompressorschoepen.

Hierdoor wordt de motor generatorisch in de afremfaze. Ook met DC injektie

in de wikkelingen blijft de regeling stug.

- 01.12.2005: proefopstelling voorbereiding met het reeds bestaande chassis

van <Harma>.

- 02.12.2005: programmering PIC's voor de pp boards zoals gebruikt voor de

player piano en voor <Harma>. PIC's 2- 8 zijn voor de aanslaggevoelige

ventielsturingen bedacht, terwijl PIC voor de sturing van de motor controller

moet instaan.

- 03.12.2005: experimentele opstelling met mini ventola blazer van Laukhuff

op een frekwentie van maximaal 75Hz. (Proeven gedaan op de bestaande <Harma>

automaat).

- 08.12.2005: bespreking met Ghislain Potvlieghe. Hij stelt voor een legering

van 95% tin en 5% antimoon te gebruiken voor de pijpen. Dit is makkelijker

te bewerken dan messing en is mechanisch behoorlijk sterk.

- 09.12.2005: Mensuurtabellen voor tin/antimoon pijpen opnieuw berekend met

de gegevens van Ghislain Potvlieghe.

- 10.12.2005: Materiaal onderzoek voor het bovenblad van de windlade. Geschikte

kunststoffen blijken problematisch. Tegen hout pleit eeuwig weer de gebrekkige

vormvastheid, homogeniteit en de gevoeligheid voor aantasting door insekten.

(houtworm). Beuk moet op grond daarvan in elk geval worden afgekeurd.

- 20.12.2005: ontwerp midi input board.

- 23.12.2005: werkvergadering met Johannes Taelman. Elektronikaontwerpen voor

de besturing van motoren en ventielen.

- 25.12.2005: Ventieltesten op de windlade van <Krum>.

- 10.01.2006: tests voor de bepaling van een optimale winddruk voor de pijpen.

- 11.01.2006: montage manometer met een bereik tot 25mBar (250mm H20 in orgelbouweenheden)

op de windlade van Krum die we gebruiken voor de experimenten. Zoektocht naar

geschikte elektronische sensoren: het blijkt nodig een idee te hebben van

de turbulenties in de windlade. Een manometer is daarvoor te traag. De pijpen

hebben behoefte aan een zo rustig mogelijke windvoorziening. Het vergroten

van de inhoud van de luchtlade is daarvoor een voor de hand liggende oplossing,

maar die moeten we verwerpen als we de idee van eenvoudige verplaatsbaarheid

willen handhaven. Immers voor een perfekte uitmiddeling en integratie van

de drukvariaties, zou een voorraadvat nodig zijn van een kubieke meter (integratie

tijd 7.5s, voor een kompressor met een opbrengst van 8 kubieke meter per minuut).

- 13.01.2006: testopstelling voor de meting van de kracht van elektromagnetische

kleppen in funktie van de ankerafstand, de aandrijfspanning en de kracht uitgeoefend

door een drukveer werkend in tegengestelde richting van de magneetkracht.

De drukveer bllijkt onontbeerlijk voor de implementatie van aanslaggevoeligheid

in dit soort kleppen.

- 16.01.2006: Nieuw ontwerp voor een PIC controller board met midi input doorgestuurd

naar Plot & Go. De files werden gemaakt door Johannes Taelman in Eagle.

- 17.01.2006: proeven met door een Dunkel servomotor aangedreven 3-schoeps

kompressor voor de opwekking van extreem lage tonen met een voldoende resolutie

voor gebruik als kwarttoonsbas instrument. Plot & Go order betaald aan

Europrint.

- 23.01.2006: Levering van de PC boards voor de midi-input buffers en de motor

besturings PIC. (Printproduktie in Hongarije!).

- 25.01.2006: Bestukking en soldering van het midi hub board.

- 26.01.2006: midi hub board blijkt niet te werken... Bug ontdekt in het printontwerp:

DIN midi ingang was verbonden met pin 3 i.p.v. pin5. Fout hersteld met draadbrugje

en doorkrabben printspoor. De midi hub werkt nu perfekt.

- 27.01.2006: Experimenteel onderzoek naar individuele PWM sturing voor elk

ventiel. De PWM waarde zou dan overeenkomen met de waarde van het velo byte.

Aftertouch wordt dan ook een mogelijkheid. Daarvoor kunnen we gebruik maken

van het reeds ontwikkelde PC board voor <Sire>. Die hebben evenwel slechts

8 uitgangen voor PWM, waardoor we niet minder dan 36 boards zouden nodig hebben...

- 31.01.2006: Paragraaf over bouw van fluiten toegevoegd in kursus akoestiek.

Morgen praktische demonstratie voor de studenten. cfr.:4021.html.

- 04.02.2006: Proeven met lineaire tandwielen voor proportionele klepbesturing.

Proeven uitgevoerd op de experimentele windlade van <Krum>, Voor <Qt>

zouden we best een autoreguleringsmechanisme voorzien uitgaand van een druksensor

in de windlade zelf. Een diafragmabesturing behoort ook tot de mogelijkheden.

- 21.02.2006: Zoektocht materialen en onderdelen bij Farnell en RS components.

- 24.02.2006: levering BYV32 dubbeldiodes.

- 09.03.2006: levering Weidmuller konnektors Farnell.

- 10.03.2006: Nieuwe proefpijpen klaar in atelier van Ghislain Potvlieghe.

Test, dit weekend.

- 12.03.2006: werkvergadering en evaluatie proefpijpen met Ghislain Potvlieghe.

Mensuurgegevens voor de testreeks uit tin/antimoon:

-

| Noot |

diameter (buitenmaat) |

sprekende lengte |

wanddikte |

labium breedte |

| 36 |

115.0mm |

124.0 cm |

0.9mm |

90mm |

| 48 |

62.5mm |

61cm |

0.9mm |

54mm |

| 60 |

41mm |

29.5cm |

0.9mm |

32mm |

| 72 |

25mm |

14.5cm |

0.9mm |

18mm |

| 84 |

16.8mm |

65mm |

0.9mm |

12mm |

Werkdruk: 80mm H20. (Te verhogen tot 90mm, met een maximum tot 150mm)

- 13.03.2006: Berekeningprogramma aangepast aan nieuwe meetgegevens en een

per individuele pijp verschillende mensuur. Ook bij toepassing van een hogere

winddruk moet deze behouden kunnen blijven.

- 14.03.2006: Berekening benodigde kompressor: 8 kubieke meter lucht per minuut

moet volstaan voor grote klusters. Bij een maximale winddruk van 120mm H20

komen we dan uit op een motor vermogen van 0.4Pk. Laukhuff type 6008-12 kan

voldoen. Gewicht van de machine: 23kg. Het voortgebrachte ruisnivo ligt dan

op maximaal 47dBA. Dempingsmaatregelen zullen zeker nodig zijn.

- 16.03.2006: Ontwerp en berekening mogelijkheden tot plaatsing van de pijpen

op de windladen. Aanpassing ontwerpsoftware voor direkte html output.

- 17.03.2006: dummy plattegrond gemaakt uit papier, voor de beoordeling van

de mogelijke organisatiewijzen van de pijpen.

- 18.03.2006: lay out (letterlijk) van de pijporganisatie, met inachtname

van de afmetingen van de te gebruiken ventielen.

Het eerste probleem hier is natuurlijk het feit dat op grond van het gebruik

van gedekte pijpen, de afstraling van het geluid sterk gelokaliseerd is ter

hoogte van de labia van de pijpen. Hierdoor kan een uiterst kompakte opstelling

van de pijpen in meer dan twee rijen niet doorgevoerd worden.

- 19.03.2006: Opmaak bestelbon voor Demar Lux (inox). Lay out alternatief

voor de pijpopstelling: twee cirkels: 400mm en 600mm doorsnede verbonden door

een licht kegelvormig middendeel. Inventarisatie van de benodigde ventielmagneten.

Het kostenplaatje alleen voor de ventielen beloopt zo'n 3800 Euro.

De onderkanten van de beide ronde gedeelten kunnen worden vervaardigd met holle

bodems in standaard afmetingen, inox 304L of 316, 3mm dikte.

- 21.03.2006: Hout voor de bovenplaat van de windlade besteld. Uiteindelijk

opteerden we voor een tropische (afrikaanse) houtsoort. De levertijd blijkt

behoorlijk lang te zijn...

- 23.03.2006: labowerk: metingen aan optocouplers voor de midi data ingang.

Het 6N137 type blijkt bij een ingangsstroom doorheen de LED van 5mA ruimschoots

sneller dan de 6N138. Pin 7 blijft onverbonden en pin 6 krijgt een weerstandje

van 280 Ohm naar de +5 voeding. Een 1MHz blokpuls verschijnt met behoud van

de symmetrie goed op de uitgang. De datasheet garandeert Baudrates tot 100kB.

Noteer dat de stroom in de midi standaard in 1983 werd vastgelegd en bepaald

op 5mA.

- 04.04.2006: soldeerwerk testschakeling met pulse en hold.

- 12.04.2006: pulse-hold board ontwerp nagezien. Nu per board goed voor 14

noten.

- 13.04.2006: levering elektromagneetkleppen vemtielen August Laukhuff.

- 22.04.2006: levering inox demar lux: flenzen en boorden 700mm en 500mm..

- 26.04.2006: nogmaals geinformeerd naar levering hout voor bovenkant windlade...

- 04.05.2006: werkplan TIG laswerk aan onderzijde windlade.

- 11.05.2006: mail naar Laukhuff i.v.m. levertermijn kompressor.

- 12.05.2006: Start TIG laswerk en assemblage windlade.

- 17.05.2006: kompressor zou morgen moeten geleverd worden... Betaling o.k.:

1700 Euro....

- 18.05.2006: de naar onze specifikaties bestelde kompressor is geleverd,

getest en goed bevonden: 0.45 Pk, 230/400 V, 1.5/0.9 A - 2800 rpm @ 50 Hz.

Debiet 8 kubieke meter per minuut bij 120 mm H2O druk.

- 19.05.2006: metingen motorkarakteristieken en bepaling van de specifikaties

voor de te gebruiken motorcontroller.

- 22.05.2006: Het pijpwerk voor de eerste 120 pijpen is klaar in het atelier

van Ghislain Potvlieghe. Draaiwerk hoofdassen: resp. 700 mm en 500 mm, dikte

25 mm, in gehard inox.

- 23.05.2006: start uittekenen lasplan onderstel en wielbasis. Levering hout

voor bovenkant windlade: Wawa hout (obeche, of met de latijnse benaming triplochiton

scleroxylon) uit Afrika. Het is een betrekkelijk lichte en ook lichtgekleurde

houtsoort die uitermate geschikt is voor houtsnijwerk. Kostprijs hout: 180

Euro. Bodemplaat (AISI 304L, 150x310x8, voor montage motor gesneden en geboord.

Motor montage met M6 trillingsdempers.

- 24.05.2006: Uitvoering lasplan volgens technische tekening

De in oranje ingekleurde delen stellen het wawa-houten bovenblad van de windlade

voor. De motor projektie is in het blauw aangegeven. Uitgevoerd: plasma snijwerk

verbinding voorste holle bodem met 150x100x3 inox kokerprofiel evenals TIG

laswerk van beide komponenten. Laswerk motor flens uitgevoerd in 15 x 10 x

150 inox met voorgeboorde bevestigingsgaten voor M5. Draaiwerk assen met eind

sleuven voor omega ringen.

- 25.05.2006: Laswerk draaiwielstel achterstuk. Draagchassis motor en motorflens

gelast. Kokerprofiel 150x100x3 vertikaal uitgesneden en dichtgelast. Voorste

as definitief gepositioneerd en afgelast. Motor moet met een 4mm dikke rubber

of neopreen dichting gemonteerd worden op de flens (trilvrij!). Onderkant

chassis afgelast. Werkfotos gemaakt

- 26.05.2006: Laswerk kraagflens op voorste holle bodem. Rondom gelast aan

de binnenzijde. Inpassen kompressor in chassis.

- 27.05.2006: Proefmontage houtwerk voor de 24 voorste pijpen (laagste oktaaf)

op flens en passing met dichtingsspanring voorzien van 12 lange M6 bouten.

Dichtingstest met kruipolie op laswerk. De vertikale as waarmee het achterwielstel

onder het chassis draait, kan worden gemaakt uit een inox M24 binnenzeskant

cilinderschroef. Eventueel kan hier een kogellager geplaatst worden. Het horizontaal

glijden kan worden verzekerd met een teflon ring.

- 28.05.2006: Foto wawa hout op frontale windlade en gezaagd en geschaafd

hout voor de bovenste windlade. De gaten kunnen slechts geboord, gezaagd en

gehoond worden wanneer de pijpen hier afgeleverd zijn. Eerste voorlopige afdichting

frontale windlade met neopreen.

- 29.05.2006: Nieuwe bepaling dispositie van de pijpen op de windlade. Voorste

windlade: 24 pijpen (1 oktaaf). Cirkelsegment in bovenlade krijgt 48 pijpen

( de hoogste twee oktaven en dus de kleinste pijpen, voor de noten 84 tot

108. De minimale afstand tussen de pijpen onderling wordt in dit gebied volledig

bepaald door de afmetingen van de magneetventielen en niet door de diameters

van de pijpen zelf). Het rechthoekig gedeelte van de bovenste windlade krijgt

dan de resterende 60 pijpen in een vier-rijige opstelling. De opstelling van

de pijpen levert wel een ontwerp dilemna op: wanneer we de pijpen van de 440Hz

diapason reeks aan een kant opstellen en de kwarttoonspijpen aan de andere

kant, dan ontstaat er een assymetrie in de klankprojektie wanneer het instrument

niet centraal wordt opgesteld, maar bvb. tegen een wand. Wanneer we de pijpen

in oplopende volgorde van toonhoogte opstellen dan zullen deze dynamische

onregelmatigheden van toon tot toon opleveren. Alleen bij een lineaire opstelling

zou dit kunnen vermeden worden, maar dan zou het instrument een lengte moeten

krijgen van bijna zes meter... Een dringend noodzakelijk experimenteel onderzoek

dringt zich trouwens op n.a.v. de bepaling van de minimale afstand tussen

de pijpen. Het is duidelijk dat een te dichte plaatsing de vlotte toonopwekking

en ook de stemming in het gedrang kan brengen. De labia van de pijpen zouden

op teoretische gronden minstens een kwartgolflengte van elkaar (of eender

welk ander obstakel) moeten verwijderd zijn.

- 30.05.2006: Extra ventielen besteld bij Laukhuff: polstermaten 35mm, 30mm

em 25mm ontbraken voor een regelmatige overgang tussen de maten van de pijpvoeten.

Materiaal- en onderdelenlijst toegevoegd aan bouwverslag in funktie van onderhoud

en technische dokumentatie.

- 31.05.2006: Herberekening en konstruktie vertikale achterwielstel as zo

dat de draaicirkel ten volle 90 graden kan zijn. Verbindingsstuk tussen oplegger

(300 x 10 x 450) en voorste deel van het chassis onder 60 graden. M24 x100

cilinderkop inbus bouten en moeren, evenals bijhorende schotelveren in inox

besteld.

- 01.06.2006: Verder las- en plasmasnijwerk. Schuine opstand stukken 60 graden

gesneden en gelast. Nieuwe, vervolledigde tekening van het frontaal aanzicht

gemaakt:. De ruimte tussen de bovenste windlade en het achterwielstel is voorbehouden

voor de besturingselektronika.

- 02.06.2006: Extra ventielen Laukhuff geleverd. Eerste positionering voorste

gedeelte chassis tegenover achterdeel. Natrekken van alle ontwerpmaten in

de reeds gelaste konstruktie. Vanaf nu moeten alle positioneringen met takels

gebeuren. Uittekenen bouwplan voor de bovenste windlade. Alles uit te voeren

in inox plaat AISI304L, dikte 3mm.

- 03.06.2006: Start laswerk aan bovenste windlade. Legframe voor houten pijpdrager

uit inox 25x10 staaf, uitgefreesd voor passing in inox boordrand, dikte 3mm.

Boorwerk spangaten voor luchtdichte afsluiting.

- 04.06.2006: Plasmasnijwerk bovenste windlade, opstanden. Aanmaak plooimallen.

Uitzetten snijstukken. Plaatslagwerk hoekstukken. Dichtlassen naden.

De konstruktie moet nog spanningsvrij gemaakt worden! Bij gebrek aan oven,

zal dit met een gasvlam moeten gebeuren... (Acetyleen brander)..

05.06.2006:

eerste voorlopige assemblage van het gehele chassis. De hoogteligging van

de bovenwindlade tegenover de onderste windlade is op de foto nog niet bepaald.

Begin uitsnijden kleppen voor de tremulant. Hiervoor moeten nog praktische

proeven worden opgezet, meer bepaald m.b.t. benodigde krachten en windafdichting

van de assen.

05.06.2006:

eerste voorlopige assemblage van het gehele chassis. De hoogteligging van

de bovenwindlade tegenover de onderste windlade is op de foto nog niet bepaald.

Begin uitsnijden kleppen voor de tremulant. Hiervoor moeten nog praktische

proeven worden opgezet, meer bepaald m.b.t. benodigde krachten en windafdichting

van de assen.- 06.06.2006: Proefkonstruktie windklep met stappenmotorbesturing.. As 6mm,

voor de afdichting moeten gasdichte kogellagers worden gebruikt. De overbrenging

naar de motor kan via een gekartelde riemschijf gebeuren. Een positiesensor

zal nodig blijken in deze aanpak. De bevestiging van de klep op de as is bijzonder

moeilijk uit te voeren.

- 07.06.2006: M24 bouten geleverd. Grootste sterkteklasse (DIN912). Deze kosten

zomaar eventjes 50 Euro per stuk... M2 inox boutjes ingekocht voor montage

klep op as. Kogellagers voor as: FAG 626.2RS, asmaat 6mm, buitenmaat 19mm

in een gasdichte uitvoering. Hele dag gewerkt aan zuiver slijpen van de klepzitting

en het balanceren van de as met gemonteerde klep.

- 08.06.2006: Opzoekwerk naar geschikte stappenmotoren en bijhorende kontrollers.

Alvast bij Farnell van Sanyo Denki, type 103H7123-0440/1 besteld voor evaluatie.

(ca. 90 Euro per stuk). De bijhorende kontrollers kosten 250 Euro per stuk.

Konstruktie bevestigingsflenzen voor de kogellagers van de tremulanten / windkleppen.

(uit inox plaat 8mm dik, gat 19.0mm, gehoond). Opzoekwerk naar een geschikte

positiesensor voor montage op de 6mm as. De Sanyo steppers zien eruit als

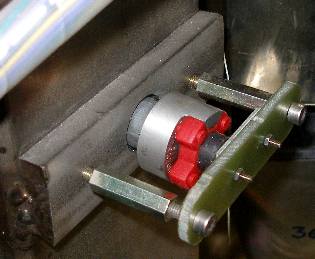

op de foto hierbij:

- 09.06.2006: Konstruktie tweede windklep voor montage in de kondukten van

de bovenste windlade. Opzoekwerk naar datasheets voor de motorcontrollers

van Sanyo Denko, ze werden niet bijgeleverd... Berekening extra voedingsbehoeften

24/36V supply. Schema uitgetekend voor het PIC board nodig voor de besturing

van de motorcontrollers. De pulse inputs cw en cww moeten een blokgolf krijgen

met duty cycle van niet meer dan 50% en een minimale pulsbreedte van 20 microsekonden.

De maximale frekwentie is 20kHz, voor een toerental van 3000 rpm.. Dat is

in elk geval ver boven het maximaal wenselijke in deze tremulant toepassing.

16Hz of, 960 rpm is ons maximum, maar aangezien de klep bij elke omwenteling

de luchtstroom tweemaal onderbreekt, moeten we de helft hiervan nemen als

maximum, dus 480 rpm, of een pulse frekwentie kleiner dan 3.2kHz (in full-step

bedrijf). Het power down signaal maakt de motor stroomloos. Bij logisch 0

op de input gebeurt dit. De step angle input laat de motor in half-stap modus

draaien wanneer het logisch nivo 0 is. Wanneer het 1 is draait de motor in

vol-stap modus. In onze toepassing is vol-stap modus aangewezen en hoeft de

PIC dit signaal dus niet te sturen..

- 14.06.2006: Pijpen voor <Qt> allemaal afgeleverd door Ghislain Potvlieghe.

Nu kunnen we de gaten in de windlade boren en frezen.. Het stemmen en intoneren

moet later gebeuren. Daarna pas kunnen de pijpdeksels allemaal dichtgesoldeerd

worden. De uiteindelijk gebruikte legering bestaan uit 95% tin, 4% antimoon

en 1% koper.

- 15.06.2006: Overleg met Johannes Taelman m.b.t. de stappenmotor sturing

van de kleppen en tremulanten. Bespreking van de toe te passen positiesensortechnologie.

- 16.06.2006: Uittekenen boorplan voor de onderste windlade uitgaand van de

werkelijke maten van de pijpvoeten in het onderste oktaaf. Levering inox schotelveren

voor montage achterwielstel (kostprijs 334 Euro!). Specifikatie en bestelling

hoofdschakelaar bij Holderbeke.

- 17.06.2006: Konstruktie inox draagbrug voor onderste stappenmotor windlade.

Uitlijning assen windklep en motor. Aanmaak askoppeling 6mm -> 1/4"

motor as.

18.06.2006:

nameten pijpen en definitieve bepaling van het hoogteverschil tussen beide

windladen: 600mm. (640mm is de hoogste mogelijkheid). Vast- en gasdicht lassen

van de bovenste windlade aan de windinlaat-kolom uit kokerprofiel 100x150.

Laswerk draagbeugel voor de stappenmotor van de bovenste windlade. Eerste

proefmontage en voorlopige uitlijning van de assen. Als asverbinding passen

we hier een 15mm Spinax elastische koppeling toe. Dit moet ook het bijgeluid

verbonden aan stappenmotoren wat dempen.

18.06.2006:

nameten pijpen en definitieve bepaling van het hoogteverschil tussen beide

windladen: 600mm. (640mm is de hoogste mogelijkheid). Vast- en gasdicht lassen

van de bovenste windlade aan de windinlaat-kolom uit kokerprofiel 100x150.

Laswerk draagbeugel voor de stappenmotor van de bovenste windlade. Eerste

proefmontage en voorlopige uitlijning van de assen. Als asverbinding passen

we hier een 15mm Spinax elastische koppeling toe. Dit moet ook het bijgeluid

verbonden aan stappenmotoren wat dempen.- 19.06.2006: Verder werk aan de windklep voor de bovenste windlade. Korrektie

van de nodige vooropening van de klep en uitlijning van de as. Om loskomen

van de drie boutjes waarmee de klep op de as vastzit te voorkomen, moet die

as op de klep worden gekleefd met silikonenrubber. (Loctite blue). Flens van

het tegenlager voor de bovenste motor vastgelast Spinax koppeling in spuitgiet

aluminium met cyaanakrylaat gelijmd op de assen. Tweede Spinax askoppeling

besteld bij MEA.

- 20.06.2006: Montage manometer op de vertikale kondukt, voor de windkleppen

en tremulanten. De drukoverbrenging is zijdelings via een aangelaste haakse

bocht. Hoewel de bocht een diameter heeft van 25mm, is het luchtgat in de

koker toch slechts op 10mm uitgeboord. De manometer heeft een gevoeligheid

van 25 mBar (250 mm H2O). Schaaldiameter 100 mm. De

behuizing is geheel in roestvast staal. De bevestiging van de (afgevijlde)

1/2" messing schroefdraad in het inox bochtstuk werd gemaakt met silikonenrubber.

Gezien de erg lage druk is daarbij geen enkel gevaar voor lekken. Ook de hechting

van de achterwand van de manometer op de vertikale kolom werd uitgevoerd met

hetzelfde materiaal. Indien ooit vervanging nodig zou zijn, moet dit met een

paletmes gebeuren. De manometer werd aan de motorzijde van de kompressor geplaatst,

naast de motorkontroller, waardoor de elektronische afregeling en het programmeren

van de kontroller wordt vereenvoudigd. (Bij <Krum>

hadden we ze elk aan een andere zijde geplaatst, wat erg onkomfortabel bleek...)

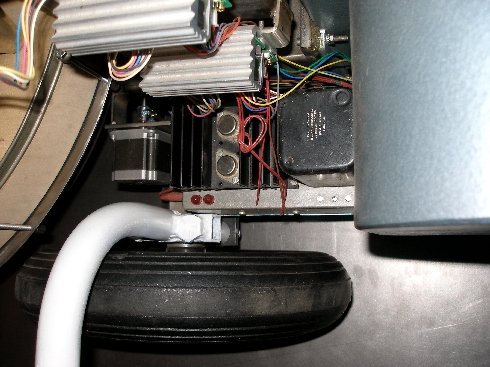

21.06.2006: Konstruktie draagbruggen voor de Sanyo motorkontrollers. Geplooid

uit inox 30x3 , beugelbreedte 100mm, opstand aan beide zijden 20mm. Montagegaten:

4mm. Draagplaat voor de kompressormotorkontroller (Leroy Somer) gesneden,

geboord (4mm) en aangelast aan de vertikale kondukt. Studie van de plaatsingsmogelijkheden

voor de diverse voedingseenheden. Bedrading kompressormotor in driehoeksschakeling.

Eerste plaatsing Sanyo motorkontrollers. De stappenmotoren, in full-step bedrijf

draaien 1.8 graden per stap. Voor 90 graden zijn dus 50 stapjes nodig. Elke

puls moet minstens 20microsekonden duren, duty cycle 50%, dus in totaal 40

microsekonden per stap. De teoretisch maximaal haalbare snelheid voor een

hoek van 90 graden (open/toe trajekt) is dan ook 2 ms..... Dit cijfer kan

natuurlijk in onze toepassing niet worden gehaald.. De wrijving op de as,

de winddruk zelf, en de eigenmassa van de windklep veroorzaken uiteraard een

inertie waardoor de motor nooit met een dergelijke snelheid kan opstarten.

Indien de motor teveel bijgeluiden zou veroorzaken, moet overwogen worden

mikrostap modus te gebruiken, ook al gaat dit ten nadele van de maximaal haalbare

kracht. De kracht op de windklep is maximaal wanneer deze in de gesloten stand

staat en de andere zijde onbelast is, een omstandigheid die zich alleen kan

voordoen bij het spelen van volledige klusters op het instrument, en dan nog

voor zover we het maximale debiet van de kompressor (8m3 / min) niet overschrijden.

Immers in dit laatste geval, zakt automatisch de geleverde druk. De worst

case kracht op de gesloten klep bij een winddruk van 100mmH20

(= 10mB = 1kPa = 1000N/m2) is, wanneer we de oppervlakte van de klep berekenen

als 100mmx150mm = 1.5dm2, 15Newton. De kracht versus snelheid kurves van de

fabrikant (Sanyo) voor de motor kontroller en stappenmotor kombinatie zoals

hier toegepast, zien eruit als:

21.06.2006: Konstruktie draagbruggen voor de Sanyo motorkontrollers. Geplooid

uit inox 30x3 , beugelbreedte 100mm, opstand aan beide zijden 20mm. Montagegaten:

4mm. Draagplaat voor de kompressormotorkontroller (Leroy Somer) gesneden,

geboord (4mm) en aangelast aan de vertikale kondukt. Studie van de plaatsingsmogelijkheden

voor de diverse voedingseenheden. Bedrading kompressormotor in driehoeksschakeling.

Eerste plaatsing Sanyo motorkontrollers. De stappenmotoren, in full-step bedrijf

draaien 1.8 graden per stap. Voor 90 graden zijn dus 50 stapjes nodig. Elke

puls moet minstens 20microsekonden duren, duty cycle 50%, dus in totaal 40

microsekonden per stap. De teoretisch maximaal haalbare snelheid voor een

hoek van 90 graden (open/toe trajekt) is dan ook 2 ms..... Dit cijfer kan

natuurlijk in onze toepassing niet worden gehaald.. De wrijving op de as,

de winddruk zelf, en de eigenmassa van de windklep veroorzaken uiteraard een

inertie waardoor de motor nooit met een dergelijke snelheid kan opstarten.

Indien de motor teveel bijgeluiden zou veroorzaken, moet overwogen worden

mikrostap modus te gebruiken, ook al gaat dit ten nadele van de maximaal haalbare

kracht. De kracht op de windklep is maximaal wanneer deze in de gesloten stand

staat en de andere zijde onbelast is, een omstandigheid die zich alleen kan

voordoen bij het spelen van volledige klusters op het instrument, en dan nog

voor zover we het maximale debiet van de kompressor (8m3 / min) niet overschrijden.

Immers in dit laatste geval, zakt automatisch de geleverde druk. De worst

case kracht op de gesloten klep bij een winddruk van 100mmH20

(= 10mB = 1kPa = 1000N/m2) is, wanneer we de oppervlakte van de klep berekenen

als 100mmx150mm = 1.5dm2, 15Newton. De kracht versus snelheid kurves van de

fabrikant (Sanyo) voor de motor kontroller en stappenmotor kombinatie zoals

hier toegepast, zien eruit als:

Het moge duidelijk zijn dat de rotatie frekwentie, voorzover we het maximaal

koppel nodig zouden hebben, zeker niet groter zal mogen zijn dan 4 Hz, wat

een tremulant frekwentie oplevert van ca.. 8 Hz. Indien haalbaar op PIC-kode

nivo zullen we wel pogen versnellingstabellen te gebruiken, om deze snelheden

zeker te kunnen halen en misschien te overschrijden.- 22.06.2006: Test stappenmotor bestuurde windkleppen. Voedingseenheid: Siemens

24V/20A Zoals te verwachten was, treden bij bepaalde pulsfrekwenties sterke

hoorbare resonanties op. Lage toerentallen blijken trouwens meer storingsgeluiden

op te leveren dan de hoogst haalbare. Uiteraard zullen deze later sterk worden

gedempt vanzodra de windlade op de inox konstruktie wordt gespannen. Kleppen

vastgezet en trillingsvrij gemaakt met Loctite Silicone Blauw (5926). Lagerhouders

definitief gepositioneerd en vastgelast. Lagers in flenzen gefixeerd met Loctite

638.

- 23.06.2006: Konstruktie nokkenschakelaar en 3-prong EEC netingang voor de

netspanningsvoorziening. De behuizing van deze schakelaar is tevens verdeeldoos

voor de verschillende komponenten die rechtstreeks netspanning nodig hebben.

Op deze schakelaar voorzien we eveneens een felrode verklikker.

24.06.2006: Bouw 5 V / 5 A voeding voor alle TTL schakelingen en de PIC boards.

Voor de transfo gebruikten we een oud militair in olie ingegoten exemplaar

uit de jaren '60. De regeling is erg rechtoe- rechtaan en maakt gebruik van

twee 78K05 regulators (2 A/ stuk). Een van de geregelde uitgangen gaat naar

de stappenmotor kontrollers (elk vraagt 500 mA). De aansluiting gebeurt met

gewone banaanstekkers (4 mm, Hirschmann). De gehele voeding werd in, en deels

buiten (koelprofiel en transfo), een spuitgiet aluminium BIM box gemonteerd.

De module wordt naast een van de voorwielen op een gelaste inox drager gemonteerd.

Alle onderdelen werden omwille van de trilvastheid met exopy (Araldite) of

blauwe silikonen vast gezet in het chassis. Het schema toont de opbouw van

de analoge voeding evenals de zes blauwe led's die vanuit het midihub board

kunnen worden geschakeld onder MIDI kontrole. Opname exakte pijpmaten door

Sebastian Bradt. Bij inventariering blijken nog 24 pijpen te ontbreken, met

name die voor het zesde en hoogste oktaaf (96.5-108)

24.06.2006: Bouw 5 V / 5 A voeding voor alle TTL schakelingen en de PIC boards.

Voor de transfo gebruikten we een oud militair in olie ingegoten exemplaar

uit de jaren '60. De regeling is erg rechtoe- rechtaan en maakt gebruik van

twee 78K05 regulators (2 A/ stuk). Een van de geregelde uitgangen gaat naar

de stappenmotor kontrollers (elk vraagt 500 mA). De aansluiting gebeurt met

gewone banaanstekkers (4 mm, Hirschmann). De gehele voeding werd in, en deels

buiten (koelprofiel en transfo), een spuitgiet aluminium BIM box gemonteerd.

De module wordt naast een van de voorwielen op een gelaste inox drager gemonteerd.

Alle onderdelen werden omwille van de trilvastheid met exopy (Araldite) of

blauwe silikonen vast gezet in het chassis. Het schema toont de opbouw van

de analoge voeding evenals de zes blauwe led's die vanuit het midihub board

kunnen worden geschakeld onder MIDI kontrole. Opname exakte pijpmaten door

Sebastian Bradt. Bij inventariering blijken nog 24 pijpen te ontbreken, met

name die voor het zesde en hoogste oktaaf (96.5-108)- 25.06.2006: Montage Siemens SITOP 24 V/ 20 A voeding. De vereiste DIN rail

werd op een inox staaf 30x10 gemonteerd met 4 M4 boutjes. De inox staaf zelf

werd vastgelast in het chassis. Op deze staaf lasten we 2 voorgeboorde draagplaatjes

voor 50 mm LED of halogeen spotlites. Deze spotjes worden in serie geschakeld

en werken dan op 24 V. De stappenmotoren hebben een worst case stroomverbruik

van 2x3A=6A terwijl de stroombehoefte voor de velo-pulsen maximaal 6.5A beloopt.

De vermogensreserve (7.5A) staat ter beschikking voor verder nog toe te voegen

ingebouwde lichteffekten.

Eerste voorlopige opmeting en uittekening van de boormal voor de pijpen op

de onderste windlade.

- 26.06.2006: Opstelling PIC specifikaties voor de stappenmotorbesturing op

grond van het tijddiagram hieronder:

Boren van de gaten voor de pijpvoeten in de cirkelvormige windlade voor de

laagste 24 pijpen. Boormaat (voor het honen) 22 mm, behalve pijp 36.5 waarvoor

het gat werd uitgeboord op 26.5 mm. Eerste proefopstelling van pijpen. Een

mechanische versteviging aan de bovenzijde van de pijpen lijkt wenselijk,

met het oog op veilige transporteerbaarheid. Gaten geboord in de onderwindlade.

Boormaat 22 mm, behalve het gat voor pijp 36.5, dat werd uitgeboord op 26.5mm.

Na het boren werden de gaten geschuurd en gehoond tot een precieze passing

van de pijpen werd verkregen.

- 27.06.2006: Overlegvergadering met Ghislain Potvlieghe: mensurering van

de 25 pijpen in het hoogste oktaaf. Hierbij wordt overwogen deze als open

pijpen uit te voeren. Immers, voor gesloten pijpen zou de eerste spektraalkomponent

dan op 6.6kHz ligen (duodecieme op noot 97) en voor de hoogste pijp (108)

op 12.5 kHz. Voor open pijpen echter op 4.4 kHz en 8.3 kHz, gevolgd door de

eerder vermelde spektraal komponenten. Het is onwaarschijnlijk dat we het

verschil als een breuk in de kontinuiteit van de klankleur zullen kunnen waarnemen.

Uitgewerkte PIC specifikatie voor de midihub-board PIC ter verifikatie bezorgd

aan Johannes Taelman. Extra kettingtakels aangeschaft voor verdere montage

van Qt.

- 28.06.2006: Schikking van de pijpen op de lage windlade definitief en gedokumenteerd,

ten behoeve van de stemmers en onderhoud. Op de tekening werd ook de schikking

van de elektromagneten aan de binnenkant aangeduid. Begin montage van de elektromagnetische

ventielen op deze windlade. Voor de pijpen/noten 36-41.5 worden Laukhuff ventielen

type 3007 08, met een doorsnede van de zitting van 35mm gebruikt. Voor de

noten 42 tot 47.5, zittingen met een doorsnede van 30mm.

De

afdichting van de zittingen werd uitgevoerd met sintetisch kalopel. De spoelen

worden trilvrij gemonteerd met tussenvoeging van 2 M4 moeren op een kussentje

uit Loctite blue siliconen. De bevestiging op het hout van de windlade wordt

uitgevoerd met voor elk ventiel twee 3 mm x 30 mm PZD kruiskop houtschroeven.

Gezien de zachtheid van het wawa hout, bleek voorboren overbodig en konden

we volstaan met het inprikken van het centergat met een els.

De

afdichting van de zittingen werd uitgevoerd met sintetisch kalopel. De spoelen

worden trilvrij gemonteerd met tussenvoeging van 2 M4 moeren op een kussentje

uit Loctite blue siliconen. De bevestiging op het hout van de windlade wordt

uitgevoerd met voor elk ventiel twee 3 mm x 30 mm PZD kruiskop houtschroeven.

Gezien de zachtheid van het wawa hout, bleek voorboren overbodig en konden

we volstaan met het inprikken van het centergat met een els.

- 29.06.2006: Afwerking ventielplaatsing onderste windlade. Test op lekken

met lichtbron. Eerste afregeling van de klepzittingen. Verwijdering van de

VDR weerstanden en de gele gekrulde aansluitsnoertjes.De VDR weerstanden spreken

immers de funktionaliteit van onze velocity sturing, waarvoor een vijfvoudige

overspanning wordt gebruikt, tegen. Soldering van de kleurgekodeerde aansluitdraden.

Regenboog kode: noot 36 = zwart, 37= bruin, 38- rood, 39= oranje, 40= geel,

41= groen, 43= blauw, 44= violet, 45= grijs, 46= wit, 47= zwart. De kwarttoonventielen

hebben dezelfde kleurkode, maar worden als een afzonderlijke kabelbundel behandeld

en naar buiten gevoerd doorheen een extra 13mm gat in de bovenplank van de

windlade.

- 30.06.2006: Bedrading onderste windlade.

Aanmaak

kabel boom en doorvoer doorheen windlade. Boren 20mm gaten voor plaatsing

quad blue LED dekoratie lampen. Bestelling van de daarvoor bestemde lampes

(Philips, 24V 0.5W). Inkoop porcelijnen lampvoetjes met extra lange aansluitdraden

voor de blauwe LED spots op het chassis. Levering van de 24 hoogste pijpjes

voor de noten 96-108. Bestelling 2 Sitop voedingen 24V/ 10A voor rail montage.

Er stak een elektrische ontwerpfout in ons eerste idee om met een enkele 24V/20A

te kunnen volstaan: de 24V voor de velo-pulsen moet immers de positieve pool

aan massa hebben, wat diametraal staat tegenover de eisen gesteld door de

stappenmotorkontroller.

Aanmaak

kabel boom en doorvoer doorheen windlade. Boren 20mm gaten voor plaatsing

quad blue LED dekoratie lampen. Bestelling van de daarvoor bestemde lampes

(Philips, 24V 0.5W). Inkoop porcelijnen lampvoetjes met extra lange aansluitdraden

voor de blauwe LED spots op het chassis. Levering van de 24 hoogste pijpjes

voor de noten 96-108. Bestelling 2 Sitop voedingen 24V/ 10A voor rail montage.

Er stak een elektrische ontwerpfout in ons eerste idee om met een enkele 24V/20A

te kunnen volstaan: de 24V voor de velo-pulsen moet immers de positieve pool

aan massa hebben, wat diametraal staat tegenover de eisen gesteld door de

stappenmotorkontroller.

- 01.07.2006: Konstruktie poten binnenzijde windlade, nodig voor de montage

enerzijds en voor het opmeten van het trajekt van de ventielen, die immers

ondersteboven moeten werken. De kracht uitgeoefend door het eigen gewicht

van de polsters moet in die positie afgetrokken worden van de aandrukkracht

van de sluitveer. De poten in de windlade werden gemaakt uit M10x120 inox

bouten, gehecht in het hout met Loctite blauwe siliconen. Indien nodig zijn

ze dus verwijderbaar door hard te trekken. Kabelgat met de bedrading langs

een zijde luchtdicht afgekit. Verder werk aan deze windlade ligt voorlopig

stil, tot de blauwe LED lampen geleverd zijn. Die moeten immers aan de binnenzijde

bedraad en afgedicht worden.

- 02.07.2006: Uittekenen op het werkstuk zelf van de exakte posities van de

pijpen voor de bovenste windlade, rekening houdend met de afmetingen van de

ventielen, de breedte van de boord en de projektie van de pijpen zelf. 18u

gewerkt aan het uitmeten en uittekenen... De boorplekken werden geprikt met

een els en met duimspijkers gemarkeerd. Om het overbrengen van de tekening

op de andere zijde van het werkstuk te vereenvoudigen, gaan we alle gaten

eerst voorboren met een 6mm boor, de kleinste maat die net lang genoeg is

om doorheen de dikte van het hout te geraken.

- 03.07.2006: Doorboren met 6mm van alle 120 gaten. Overtekenen werkplan op

de andere zijde van de bovenplank van de windlade. Uitboren van de pijpgaten

op een diepte van 45mm. Te gebruiken boormaten: 22mm [MK3] (voor de noten

48-76.5), 17mm [MK2] (voor de noten 77-84.5), 13.5mm [MK2] (voor de noten

85-108). Tegenboren van de luchtgaten ( 20mm diep) en de ventielzittingen

in kleinere boormaten: 16mm [MK2](voor de noten 48-53.5), 14mm [MK2](voor

54-59.5), 13.5mm [MK2] (voor 60-62.5), 13mm (voor 63-76.5), 11.5mm (voor 77-84.5)

en 10mm (voor 85-108). De ventielopeningen kunnen op deze wijze kleiner worden

genomen van de diameter van de pijpvoet. Bovendien kunnen de pijpen nu zonder

gevaar volledig diep op de windlade worden gezet. Nameten breedte van het

labium en opname van deze meetgegevens in de mensuurtabel.

- 04.07.2006: Proefplaatsing van de ventielen. Bepaling van de plaatsing van

de kabelboomdoorvoeren en de eventuele pijpbelichting. Inkoop Loctite siliconen

voor de plaatsing van de ventielen op de windlade. Inkoop: Houtschroeven 3.0

x 30, kruiskop, voor bevestiging ventielen. Monteren en afregelen van de 24

ventielen voor het hoogste oktaaf. (96-108) Montage zoals in de onderste windlade:

op 2 M4 moertjes ingekleefd met Loctite blauw.

- 05.07.2006: Montage en afregeling 24 ventielen voor de noten 84-95.5

Berekening van de benodigde ruimte voor de plaatsing van de besturingsprinten.

Berekening van de schuine opstand naar de onderzijde van de schaal van de

hoge windlade. Dit verbindingsprofiel (30x50x3) wordt onder 60 graden geplaatst

en raakt het centrum van de achtercirkel van de bovenste windlade. Levering

van de tien bestelde blauwe quad-LED lampjes. Kost 350 Euro...

Berekening van de benodigde ruimte voor de plaatsing van de besturingsprinten.

Berekening van de schuine opstand naar de onderzijde van de schaal van de

hoge windlade. Dit verbindingsprofiel (30x50x3) wordt onder 60 graden geplaatst

en raakt het centrum van de achtercirkel van de bovenste windlade. Levering

van de tien bestelde blauwe quad-LED lampjes. Kost 350 Euro...

- 06.07.2006: Montage en afregeling ventielen 72-83.5. Plaatsing blauwe quad-LED's

van Philips op de onderste windlade. Volgieten van het overblijvende deel

van deze 20mm gaten met een mortel uit 50% epoxyhars en 50% zuiver wit kwartszand.

Op deze wijze kunnen de cilindervormige gaten alvast geen turbulenties en

sekondaire resonanties meer doen ontstaan in de windlade. Vanzelfsprekend

garandeert dit tevens ook een perfekte luchtdichte afsluiting. Aansluitdraden

lampjes aangesoldeerd op de soldeerlippen gemonteerd in het midden van de

binnenkant van de windlade. De dikke rode draad is de gemeenschappelijke positieve

pool van de 24V voeding, terwijl de zwarte draad de schakeldraad is voor de

lampjes aan de kromatische kant en de blauwe draad die voor de lampjes aan

de kwarttoonskant. Vastlassen van de schuine drager van de bovenste windlade.

Finalisatie van het printontwerp voor de kleppen sturingen met aanslaggevoeligheid.

(PIC boards)

- 07.07.2006: Uitgutsen en beitelen van de passing van de bovenwindlade op

het inox deel. Dit moet op een halve millimeter nauwkeurig gebeuren, zodat

de dichtingsband in neopreen een gelijkmatige druk uitoefent op alle plaatsen

van het hout. Zoniet bestaat immers gevaar op kromtrekken na verloop van tijd.

Bestelling bij Europrint van de twaalf nodige PC boards voor de ventielbesturing.

Levering extra spinax elastische askoppelingen voor de stappenmotoren door

MEA.

- 08.07.2006: Gladschuren van de passing met een schuurblok. Boren gaten voor

de drie quad-led's in de bovenste windlade evenals van de twee doorvoergaten

voor de kabelbomen (2 x 68 geleiders). Montage en eerste afregeling ventielen

60-71.5. Vast monteren met silicone-kit van de halogeen LED sockets onderaan.

(Inox M3 boutjes).

- 09.07.2006: Montage en eerste afregeling ventielen 48-59.5 op de bovenste

windlade. Ingieten met kwarts-epoxymortel van de LED-gaten. Meteen M8 oogbouten

voor de kabelgeleiding mee ingegoten. Solderen van de gemeenschappelijke positieve

voedingsaansluitingen van alle 121 ventielen.

- 10.07.2006: Bedrading nokkenschakelaar en voedingsspanningsvoorziening naar

alle komponenten.

Plaatsing van de twee 24V Siemens Sitop voedingen op opgelaste DIN rail. Plaatsing

van de 12V/ 50A Sunpower SPS600-P12 voeding. Lassen van draagprofiel daarvoor.

Aanmaak kabelbundel voor de netspanningsvoerende bedrading. In de nokkenschakelaar

bouwden we meteen de enige nog overblijvende quad LED in, als monitor voor

de spanning. Werkvergadering met Johannes Taelman. Op zoek naar geschikte

Hall-effekt positiesensoren en data acquisitie chips voor de positionering

van de windkleppen. De Melexis MIX90316 geintegreerde Hall sensor met DSP

aan boord ziet er veelbelovend uit. (cfr.http://www.melexis.com )

Plaatsing van de twee 24V Siemens Sitop voedingen op opgelaste DIN rail. Plaatsing

van de 12V/ 50A Sunpower SPS600-P12 voeding. Lassen van draagprofiel daarvoor.

Aanmaak kabelbundel voor de netspanningsvoerende bedrading. In de nokkenschakelaar

bouwden we meteen de enige nog overblijvende quad LED in, als monitor voor

de spanning. Werkvergadering met Johannes Taelman. Op zoek naar geschikte

Hall-effekt positiesensoren en data acquisitie chips voor de positionering

van de windkleppen. De Melexis MIX90316 geintegreerde Hall sensor met DSP

aan boord ziet er veelbelovend uit. (cfr.http://www.melexis.com )

- 11.07.2006: Berekening toepasbaarheid van de Melexis draaipositie sensor..

Zoektocht naar geschikte lateraal gemagnetiseerde permanente magneten voorzien

van een gecenterd gat van 6mm. Bestelling regenboogkleurdraden bij Farnell.

Bedrading motorcontroller (kabelboom naar het midihub board).

- 12.07.2006: Levering kleurdraden Farnell. Start bedrading in regenboog draad

van alle ventielen op de bovenste windlade. Kleurkode bedrading: zwart = 48,

58, 68, 68, 88, 98, 108 in de kromatische bundel en eveneens zwart voor 48.5,

58.5, 68.5, 78.5, 88.5, 98.5 in de kwarttonenbundel. Ontwerp schakelingen

rond de positiesensor van Melexis (MLX90316). Bedradingsplan

opgesteld.

- 13.07.2006: Eerste elektrische test van het netspanningsgedeelte. De nokkenschakelaar

blijkt intern te knisperen en geeft ozon vrij... Eerste voorlopige programmering

van de motorkontroller. Eerste test van de motor: draairichting aangepast,

grondige smering uitgevoerd met syntetische olie. Zonder de windladen erop,

gaan de windkleppen vanzelf meedraaien en veroorzaken en spektakulair infrasoon

geluid.... Klaarblijkelijk zit het goed snor met hun lagering. Manometer blijkt

het ook goed te doen. Opstelling eerste volledige midi-implementatie tabel

in overleg met komponisten en gebruikers.

- 14.07.2006: Verdere uitwerking van de volledige bedradingstabellen voor

de windladen, met aangegeven van de gebruikte kleurkodering en de aansluitingen

van de Weidmuller konnektoren. Solderen draadbundel bruin voor de noten/ventielen

49, 49.5, 59, 59.5, 69, 69.5, 79, 79.5, 89, 89.5, 99, 99.5. Konstruktie draagpoten

voor omkering windlade. Aansluiting Weidmuller konnektor voor de kwarttonen

op de onderste windlade. Positionering van de de pijpen op de bovenste windlade

ziet eruit als:

- 15.07.2006: Lassen draagbeugels voor de velo/hold boards onder de windlade.

Inox 15 x 2 strip met inleg in 15 x 10. In deze beugels worden de polykarbonaat

dragers voor de gedrukte schakelingen opgehangen en vastgezet. Solderen draadbundel

bruin voor de noten/ventielen 50, 50.5, 60, 60.5, 70, 70.5, 80, 80.5, 90,

90.5, 101, 101.5. Inlassen L-profiel 30x30 voor de montage van de printen

voor de lage windlade op een stuk polykarbonaat. Uitsnijden print dragers

in polykarbonaat. Aansluiting Weidmueller konnektor voor de normale tonen

op de onderste windlade.

- 16.07.2006: Ontwerp draagstruktuur en voedingsrails voor de velo/hold boards..Aanlassen

draagprofielen voor het midihub board en en midi ingangskonnektors.Solderen

draadbundels rood en oranje voor de noten/ventielen 51 - 103

- 17.07.2006:Solderen draadbundels geel / groen/ blauw voor de noten/ventielen

52-53-54 -> 104,105,106. Elektrische test van alle ventielen in werkingspositie.

- 18.07.2006: Solderen draadbundels grijs/wit. Dichten kabelboomgaten.. Totaal

draadverbuik: 362m. Aansluiting Weidmueller konnektoren voor de kwarttoonspijpen

op de bovenste windlade. (Q-side). Zoektocht naar geschikte neopreen afdichtingsband.

- 19.07.2006: Bundeling Weidmueller konnektoren naar polykarbonaat montageplaat

voor de PC boards. Bedrading kabelboom stappenmotorkontrollers naar midihub

board. Levering PC boards van EuroCircuits.

- 20.07.2006: Aanmaak kabelbundels. Een bundel voor de normale kromatische

notenreeks, een andere voor de kwarttonen. Bestukking van de eerste testprint

voor de velo/hold besturing van de toonventielen. Inventarisatie van de nodige

onderdelen: nazicht voorraden. BS250's moeten zeker besteld worden. Het data

sheet staat in Philips Semiconductor Book SC07, 1994.

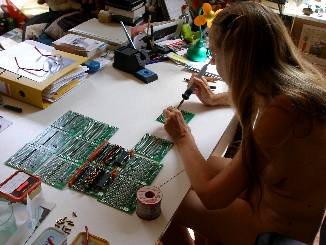

- 21.07.2006: Ontbrekende onderdelen besteld bij Farnell. Moniek Darge helpt

mee met het soldeerwerk van de twaalf velo/hold boards.

Boards voor de besturing van de onderste windlade zo goed als afgewerkt. Polykarbonaat

drager daarvoor uitgeboord (4.1mm gaten voor messing M4 bouten) en voorzien

van roodkoperen voedingsrails.Draaien van de koperen verbindingsbussen op

de draaibank. BS250 is niet te vinden bij Farnell. Een alternatief type is

BSP254A, waarbij de A suffix belangrijk is want het gewone BSP254 type heeft

een andere pinning! Het moet in elk geval een P-channel enhancement mode vertical

D-MOS transistor type zijn.

Boards voor de besturing van de onderste windlade zo goed als afgewerkt. Polykarbonaat

drager daarvoor uitgeboord (4.1mm gaten voor messing M4 bouten) en voorzien

van roodkoperen voedingsrails.Draaien van de koperen verbindingsbussen op

de draaibank. BS250 is niet te vinden bij Farnell. Een alternatief type is

BSP254A, waarbij de A suffix belangrijk is want het gewone BSP254 type heeft

een andere pinning! Het moet in elk geval een P-channel enhancement mode vertical

D-MOS transistor type zijn.