|

<Puff>

Godfried-Willem

RAES

2003-2007

|

<Puff>

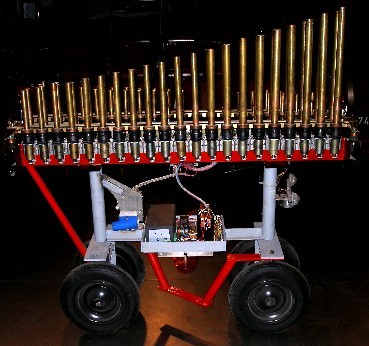

This robot realizes a percussive organ in which every single note is driven

by an individual small bellow. All of these bellows are on their turn driven

by strong and fast operating solenoids and hence, produce a single but precisely

controllable puff of wind on each stroke of the solenoid. The instrument has

no equivalent in existing musical instruments. It has 84 different notes. The

compass is 3.5 octaves and the instrument is tuned in equal temperament quartertones

( 2^(1/24) intervals). The scale starts at midi note 55 (equivalent to the lowest

note on the violin) running upward to 96. Because of its extended range in the

high treble and its quartertone tuning, this robot lends itself particularly

well to music using spectral harmony techniques. If enough energy is send to

the solenoids, the pipes can also be made to overblow. In this case, the duodecimo

will sound, since we used closed pipes.

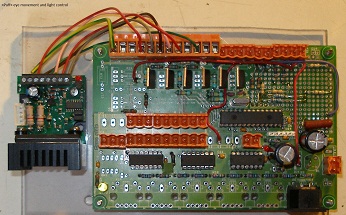

Musical dynamics are implemented by applying pulse width modulation techniques

in the driver circuits. The pulses can vary in the range 1ms to 80ms. The circuitry

used is very similar to that developed for our <Vibi>

, <Player Piano> and <Tubi>

automaton, although in this case, we did not use hardware timers (Intel 8054)

but six PIC controllers, thus avoiding the necessity of yet another dedicated

laptop computer. The picture below shows an assembly of solenoid and bellows

as used in this robot:

The power supply for the solenoids is 24V dc, 120A peak such that simultaneous

strokes on all bellows, does not burn out the power supply. The power for the

solenoids should come up only after initialization of the PIC controllers. Hence

always first switch on the mains power (with the 24V feed fully off) and after

that, the 24V power switch. The piston-cylinder combinations are custom made

by Airpot Corporation. They are made of Pyrex glass (fragile!) and have an outside

diameter of 48.5mm (1.9"). Inner bore: 44,5mm (1.75"). The height

of the cylinders, including the closing caps is 50mm. The stroke is 25.4mm (1")

and thus the volume of air compressed equals 40cc (2.4 cu "). The site

of the manufacturer is at: http://www.airpot.com. If anybody would be interested

in using these devices, a word of warning is not misplaced here: these devices

are terribly expensive (1 airpot costs 322 € and the solenoids go for 180€

each, thus one single note mechanism will cost you no less then 502€)

Each PIC controller steers 16 notes. There are six PIC boards in the instrument,

all working in parallel. Since the PIC's take MIDI as input signal, we do not

need a laptop in this case to control the instrument. The midi channel is fixed

in the firmware to channel 13. The firmware is available from the puff

directory on this site. Look for the puffx.asm files.

Mapping:

Midi note range: 55-96 for the normal chromatic pitches and 7-49 for the notes

a quarter tone higher. Within our programming environment for real time composition,

<GMT>, fractional midi notes can be used: 55, 55.5, ... 60, 60.5, 61,

61.5 ....96, 96.5

Note Off commands are not required. Velocity is implemented and has a wide

control range. On high velocity values, the pipes may overblow. Maximum repetition

rate is compromised by the duration of the pulses and thus by the velocity value

requested. When the pulses are 80ms long, the repetition rate cannot exceed

1/ (80ms + 30ms) = 9Hz, or 9 notes a second. At the smallest practical velocity

values, the maximum repetition rate is limited by the mechanics of the solenoid-bellows

assembly. The fastest possible rate is ca. 30Hz. At velocity levels of 127 (=40ms)

the repetition rate should be kept below 12.5Hz, otherwise the airpot will stick

high and have no audible effect. More over, the solenoids risk burning out.

At velo level 64 (-20ms) 25Hz is the maximum. The mechanical maximal repetition

rate requires velocity levels below 42. The lower values giving the best musical

results.

Midi Implementation Table:

| Midi Command |

byte1 |

byte2 |

remarks |

| Note Off |

notes: (lights)

[53,54],100-105, 120-122

123, 124

|

-

release not implemented

not yet mounted, but implemented in the firmware

|

the note off command is not required for the pitched notes |

| Note On |

7 - 48 (Quartertones)

55-96 (Normal tones)

100, 101,102

104,105 (orange lights)

120

121

122

123, 124

|

velo implemented (0-64)

velo implemented (0-64)

rotating orange flashlight (3-bit binary control)

note on/off only

Red LED under motor ctrl board (on/off)

White LED, Left eye

White LED, Right eye

To be mounted. PWM controlled lights.

|

|

| Note Pressure |

not implemented |

- |

|

| Controllers |

30 |

Eye motor position 0-63= left, 64=center, 65-127=right |

|

| |

31 |

Motor speed (default is 64) |

|

| |

66 |

on/off controller |

|

| |

67 |

calibrate left sensor for motor movement |

|

| |

68 |

calibrater right sensor for motor movement |

|

| |

69 |

calibrate center position for motor movement and eyes |

|

| |

90 |

interactive PIR sensor dependent eye movement

- 0 = disabled

- 1 = integrated behaviour

- 2 = fast direct mapping

- 3 = fast integrator

- 4 = relaxed integrator

|

|

| |

123 |

all notes off |

|

| Channel Aftertouch |

not implemented |

|

|

| Program Change |

not implemented |

|

|

| Pitch Bend |

not implemented |

|

|

The <Puff> robot also has a MIDI Output, used for firmware debug but

also for reading the triggers from the build in movement sensors. The output

channel equals the input channel. Details to be published in due time.

The hard/firmware mapping was designed as:

Power supply circuit:

Quartertone pipes

Our first experiments

were directed to constructing the pipes for <Puff>

from PVC material. Later we decided to go for brass pipes. Long

term tuning stability and clarity of speech being the main concern. The type

of brass used for the pipes became Ms63-F45 (hard) [440-540 M/mm2 tensioning

strength, Brinell Hardness 135, ASTM (USA) 270-274 = AFNOR UZ36 - DIN CuZn37].

This is the same material we had used before for the construction of tubular

bells. The blocks where made of brass staff material DIN CuZnPb3 = ASTM 360

= AFNOR UZ39PB2, Brinell Hardness 90). The pipes stand on a round base cut from

red copper staff material, 50mm diameter and 10mm thickness]. The windholes

and reaming for the pipes in the stand were made on a lathe.

Quartertone pipes made of brass:

note: diameters mentioned in the table are internal sizes. Add 2mm for

external diameters!

- Diam: 30 length: 413 L-ak= 431 frequency: 196.8886

Note: 55

- Diam: 30 length: 400 L-ak= 419 frequency: 202.6579

Note: 55.5

- Diam: 30 length: 388 L-ak= 407 frequency: 208.5962

Note: 56

- Diam: 30 length: 377 L-ak= 395 frequency: 214.7086

Note: 56.5

- Diam: 30 length: 366 L-ak= 384 frequency: 221

Note: 57

- Diam: 30 length: 355 L-ak= 373 frequency: 227.4758

Note: 57.5

- Diam: 30 length: 344 L-ak= 363 frequency: 234.1413

Note: 58

- Diam: 30 length: 334 L-ak= 352 frequency: 241.0022

Note: 58.5

- Diam: 30 length: 324 L-ak= 342 frequency: 248.0641

Note: 59

- Heigth of pipe base: 50

- Total length of tube for diameter 30 required = 3301 mm

- Diam: 28 length: 315 L-ak= 332 frequency: 255.3329

Note: 59.5

- Diam: 28 length: 306 L-ak= 323 frequency: 262.8148

Note: 60

- Diam: 28 length: 296 L-ak= 314 frequency: 270.5158

Note: 60.5

- Diam: 28 length: 287 L-ak= 305 frequency: 278.4426

Note: 61

- Diam: 28 length: 279 L-ak= 296 frequency: 286.6015

Note: 61.5

- Diam: 28 length: 270 L-ak= 288 frequency: 294.9996

Note: 62

- Diam: 28 length: 262 L-ak= 279 frequency: 303.6438

Note: 62.5

- Diam: 28 length: 254 L-ak= 271 frequency: 312.5412

Note: 63

- Diam: 28 length: 246 L-ak= 264 frequency: 321.6994

Note: 63.5

- Heigth of pipe base: 46

- Total length of tube for diameter 28 required = 2613 mm

- Diam: 26 length: 240 L-ak= 256 frequency: 331.1258

Note: 64

- Diam: 26 length: 233 L-ak= 249 frequency: 340.8286

Note: 64.5

- Diam: 26 length: 226 L-ak= 242 frequency: 350.8156

Note: 65

- Diam: 26 length: 219 L-ak= 235 frequency: 361.0953

Note: 65.5

- Diam: 26 length: 212 L-ak= 228 frequency: 371.6762

Note: 66

- Diam: 26 length: 206 L-ak= 222 frequency: 382.5672

Note: 66.5

- Diam: 26 length: 199 L-ak= 215 frequency: 393.7772

Note: 67

- Diam: 26 length: 193 L-ak= 209 frequency: 405.3158

Note: 67.5

- Diam: 26 length: 187 L-ak= 203 frequency: 417.1924

Note: 68

- Heigth of pipe base: 42

- Total length of tube for diameter 26 required = 2088 mm

- Diam: 24 length: 183 L-ak= 197 frequency: 429.4171

Note: 68.5

- Diam: 24 length: 177 L-ak= 192 frequency: 442

Note: 69

- Diam: 24 length: 171 L-ak= 186 frequency: 454.9516

Note: 69.5

- Diam: 24 length: 166 L-ak= 181 frequency: 468.2827

Note: 70

- Diam: 24 length: 161 L-ak= 176 frequency: 482.0044

Note: 70.5

- Diam: 24 length: 156 L-ak= 171 frequency: 496.1282

Note: 71

- Diam: 24 length: 151 L-ak= 166 frequency: 510.6659

Note: 71.5

- Diam: 24 length: 146 L-ak= 161 frequency: 525.6296

Note: 72

- Diam: 24 length: 142 L-ak= 157 frequency: 541.0317

Note: 72.5

- Total length of tube for diameter 24 required = 1683 mm

- Diam: 22 length: 138 L-ak= 152 frequency: 556.8851

Note: 73

- Diam: 22 length: 134 L-ak= 148 frequency: 573.2031

Note: 73.5

- Diam: 22 length: 130 L-ak= 144 frequency: 589.9992

Note: 74

- Diam: 22 length: 126 L-ak= 139 frequency: 607.2875

Note: 74.5

- Diam: 22 length: 122 L-ak= 135 frequency: 625.0824

Note: 75

- Diam: 22 length: 118 L-ak= 132 frequency: 643.3987

Note: 75.5

- Diam: 22 length: 114 L-ak= 128 frequency: 662.2517

Note: 76

- Diam: 22 length: 111 L-ak= 124 frequency: 681.6572

Note: 76.5

- Diam: 22 length: 107 L-ak= 121 frequency: 701.6313

Note: 77

- Heigth of pipe base : 40

- Total length of tube for diameter 22 required = 1375 mm

- Diam: 20 length: 105 L-ak= 117 frequency: 722.1906

Note: 77.5

- Diam: 20 length: 101 L-ak= 114 frequency: 743.3524

Note: 78

- Diam: 20 length: 98 L-ak= 111 frequency: 765.1343

Note: 78.5

- Diam: 20 length: 95 L-ak= 107 frequency: 787.5544

Note: 79

- Diam: 20 length: 92 L-ak= 104 frequency: 810.6316

Note: 79.5

- Diam: 20 length: 89 L-ak= 101 frequency: 834.3849

Note: 80

- Diam: 20 length: 86 L-ak= 98 frequency: 858.8342

Note: 80.5

- Diam: 20 length: 83 L-ak= 96 frequency: 884

Note: 81

- Diam: 20 length: 81 L-ak= 93 frequency: 909.9031 Note:

81.5

- Total length of tube for diameter 20 required = 1138 mm

- Diam: 18 length: 79 L-ak= 90 frequency: 936.5654

Note: 82

- Diam: 18 length: 77 L-ak= 88 frequency: 964.0088

Note: 82.5

- Diam: 18 length: 74 L-ak= 85 frequency: 992.2564

Note: 83

- Diam: 18 length: 72 L-ak= 83 frequency: 1021.332

Note: 83.5

- Diam: 18 length: 69 L-ak= 80 frequency: 1051.259

Note: 84

- Diam: 18 length: 67 L-ak= 78 frequency: 1082.063

Note: 84.5

- Diam: 18 length: 65 L-ak= 76 frequency: 1113.77

Note: 85

- Diam: 18 length: 62 L-ak= 74 frequency: 1146.406

Note: 85.5

- Diam: 18 length: 60 L-ak= 72 frequency: 1179.998

Note: 86

- Total length of tube for diameter 18 required = 959 mm

- Diam: 16 length: 60 L-ak= 69 frequency: 1214.575

Note: 86.5

- Diam: 16 length: 58 L-ak= 67 frequency: 1250.165

Note: 87

- Diam: 16 length: 56 L-ak= 66 frequency: 1286.797

Note: 87.5

- Diam: 16 length: 54 L-ak= 64 frequency: 1324.503

Note: 88

- Diam: 16 length: 52 L-ak= 62 frequency: 1363.314

Note: 88.5

- Diam: 16 length: 50 L-ak= 60 frequency: 1403.262

Note: 89

- Diam: 16 length: 48 L-ak= 58 frequency: 1444.381

Note: 89.5

- Diam: 16 length: 47 L-ak= 57 frequency: 1486.705

Note: 90

- Diam: 16 length: 45 L-ak= 55 frequency: 1530.269

Note: 90.5

- Total length of tube for diameter 16 required = 823 mm

- Diam: 14 length: 45 L-ak= 53 frequency: 1575.109

Note: 91

- Diam: 14 length: 43 L-ak= 52 frequency: 1621.263

Note: 91.5

- Diam: 14 length: 42 L-ak= 50 frequency: 1668.77

Note: 92

- Diam: 14 length: 40 L-ak= 49 frequency: 1717.668

Note: 92.5

- Diam: 14 length: 39 L-ak= 48 frequency: 1768

Note: 93

- Diam: 14 length: 38 L-ak= 46 frequency: 1819.806

Note: 93.5

- Diam: 14 length: 36 L-ak= 45 frequency: 1873.131

Note: 94

- Diam: 14 length: 35 L-ak= 44 frequency: 1928.018

Note: 94.5

- Diam: 14 length: 34 L-ak= 42 frequency: 1984.513

Note: 95

- Total length of tube for diameter 14 required = 720 mm

- Diam: 12 length: 34 L-ak= 41 frequency: 2042.664

Note: 95.5

- Diam: 12 length: 32 L-ak= 40 frequency: 2102.518

Note: 96

- Diam: 12 length: 31 L-ak= 39 frequency: 2164.127

Note: 96.5

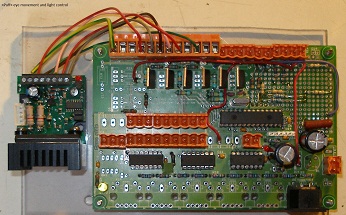

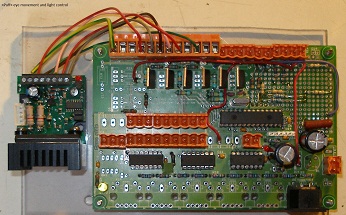

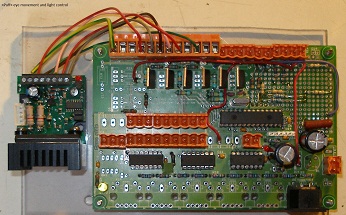

An extra feature of this robot is that we gave it movable 'eyes'.

To achieve this a stepping motor controlling the position of a paired couple

of lights is used. The schematic is very straightforward:

The midi mapping for the control of eye movement will be clear

for the mapping table above. The stepping motor is MAE HY200-2220-018C5, Type

4240593 EC862773D, a four phase type with 200 steps per revolution.

Two orange lights are fitted on the front and back side of the

robot. These are mapped on midi notes 104 and 105. In 2007 we added a rotating

orange light underneath the robot. This light is mapped on notes 100, 101, 102.

Note 100 serves as msb and 102 as lsb, such that a 3 bit speed and light strength

control is possible. As yet, the uses of the one and only free pin on board

4 , mapped on note 103 is still to be determined.

Technical specifications:

- size: 1500mm(L) x 400mm(W) x 1480mm(H)

- weight: ca. 250kg

- Power: 230V ac , 400Watt.

- Tuning: in quartertones, based on A=442 Hz

- Ambitus: 3.5 octaves (Midi 55 to 96)

- Sensors: two PIR movement sensors and two proximity sensors for the motor

control.

- Maximum sound pressure level: to be determined

- control: Puff can respond to midi commands through its midi port. It listens

to channel 13.

- Insurance value: 54.000 Euro.

Design, research and construction: dr.Godfried-Willem

Raes

Collaborators on the construction of this robot:

- Mark Maes (pipe construction, tuning & intonation)

- Bert Vandekerkhove (mounting, requisites)

- Johannes Taelman (firmware PIC microcontrollers, 2003)

- Kristof Lauwers (GMT-coding)

- Moniek Darge (painting and coloring advise)

As soon as it was ready, this robot became an integral part of the <M&M>

robot orchestra.

Music composed for <Puff>:

- Godfried-Willem Raes

- "Geropuff" for <Puff> and invisible instrument (2004)

- "Preliminary Puffs", for <Puff> and invisible instrument.(2003)

- "Qua Puff", for Puff and radar controlled invisible instrument

(2004)

- Sebastian Bradt "The Kobirds" (2004) [available

on CD LPD012]

- Kristof Lauwers "Nieuw interaktief stuk" (2004)

Nederlands:

<Puff>

Puff is een nogal merkwaardig soort robot orgel, waarbij er evenveel

blaasbalgen zijn als orgelpijpen! Door deze aanpak werd een volledige en volstrekt

polyfone aanslaggevoeligheid gerealiseerd. Elke pijp wordt vanuit een eigen,

door een elektromagneet aangedreven balgje, van lucht voorzien. Door pulsbreedte

modulatie van de stroom door de spoel, kan de luchthoeveelheid heel nauwkeurig

worden geregeld. In tegenstelling tot een traditioneel orgel echter, leveren

de hier gebruikte balgjes geen ononderbroken luchtstroom, maar slechts een enkele

windstoot: een puf. Vandaar ook de naam van deze robot. Het gehele instrument

is gestemd in kwarttonen en heeft een tessituur van drie en een half oktaaf.

De basisdiapason voor het instrument is 442Hz. De laagste noot komt overeen

met de laagste noot van de viool, in midi termen, noot 55. De tessituur loopt

door tot noot 96. De intervallen zijn telkens 2^(1/24) groot. De toonhoogte

is in enige mate afhankelijk van de aanblaassterkte, wat inflekties mogelijk

maakt. Bij grote aanblaassterktes, kunnen de pijpen ook overgeblazen worden.

Aangezien we gesloten (gedekt, in het orgeljargon) pijpen gebruikten, klinken

de noten dan een duodeciem hoger, wat de tessituur uitbreidt tot 115. De gemonteerde

kombinatie van elektromagneet (Lucas Ledex Inc. type FRUXAC64700, cat. nr. 195115-002)

en balg (Airpot 73710-6) ziet eruit als:

Een kleine waarschuwing voor potentiele nabouwers: deze kombinaties kosten

502€ per stuk...

Voor het pijpmateriaal werd een harde soort messing gebruikt: Ms63-F45 (DIN

CuZn37 = werkstof 2.0321). Voor de kernen, handmatig gevijld uit massief messingstaaf,

de zachtere legering Ms58 (DIN CuZn39Pb3 = werkstof 2.0401), die echter niet

te lassen is. De pijpassemblage werd dan ook met zilver-solderen uitgevoerd.

Het uitfrezen van de pijpvoeten in roodkoper en van de windgaten gebeurde op

de draaibank.

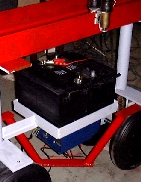

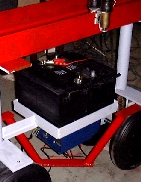

De voeding werd aanvankelijk opgebouwd met twee heel zware 12V loodakkus (100Ah)

voorzien van een permanent aangesloten lader, maar zowel om ekologische als

ekonomische redenen, voorzagen we Puff in 2007 van een geheel nieuwe voeding.

De akkus hadden immers een levensduur van twee tot hooguit drie jaar en waren

aan vervanging toe. De nieuwe voeding maakt gebruik van een Siemens Sitop 24V/20A

schakelende voeding met konvektiekoeling gebufferd middels twee 150mF/40V bekerelkos.

In 2010 werden aan <Puff> enkele nieuwe features toegevoegd: twee PIR

sensors stellen de robot nu in staat om menselijke bewegingen te volgen en daarop

te reageren middels bewegingen van de twee ogen. Voor de besturing van de stappenmotor

en de witte LED's in de ogen, werd een extra PIC microcontroller ingezet.

<Puff> luistert naar midi kommandos op kanaal 13.

Bouwdagboek:

Omdat ons vaak wordt gevraagd hoeveel werk en tijd kruipt in,

en nodig is voor, het bouwen van een muzikale robot, hebben we ook voor <Puff>

een beknopt bouwdagboek bijgehouden:

- 03.11.2003: eerste ideen en konkrete tekeningen naar aanleiding van een

aanbieding van een stel elektromagneten met balgen uit een fabrieksrestant.

- 05.11.2003: Levering van de partij elektromagneten; 84 stuks blijken intakt

en bruikbaar.

- 06.11.2003: opmetingen karakteristieken elektromagneten, luchtdruk en debiet

van de balgjes. De elektromagneten zijn type 195115-002 van Lucas Ledex Dormeyer

(dat bedrijf, gevestigd in Vandalia, Ohio, lijkt wel zowat een monopolie positie

te hebben op de markt van kwaliteits elektromagneten...) en zijn gewikkeld

voor een nominale spanning van 23.5V. De DC weerstand, koud, is 3.6 Ohm. De

nominale stroom per spoel komt daarmee op 6.5A te liggen. De repetitiesnelheid,

bij aansturing met pulsen gaande van 3 tot 80ms, kan maximaal 30Hz zijn. De

voeding zal behoorlijk zwaar dienen te zijn: bij gelijktijdige aansluiting

van alle spoelen, zouden we gedurende 80 ms een stroombehoefte hebben van

maar liefst 798A... Buffering met heel grote elektrolieten en/of met een zware

loodakku (24V/ 100Ah) lijkt dan ook aangewezen, evenals uiteraard, een limitering

via serialisatie in de software. In elk geval zal voor de bedrading een behoorlijk

zware draadsektie gebruikt moeten worden.

- 07.11.2003: begin konstruktie stalen chassis. De spoelen worden om en om

gemonteerd op twee lengtes L profiel 100x100x8, met een lengte van 1390mm.

Er zijn vier rijen spoelen en elke rij telt 21 spoelen. Hoofdchassis geboord,

zijstukken in kokerprofiel (100x50*x380) uitgezaagd en klassiek gelast, vanwege

de eerder grote profielsterkte. Besprekingen mogelijkheid tot gebruik van

PIC controllers voor direkte aansturing vanuit midi met Johannes Taelman.

Specifikatie van de nodige schakelfunkties. Minstens zes PIC controllers zijn

nodig.

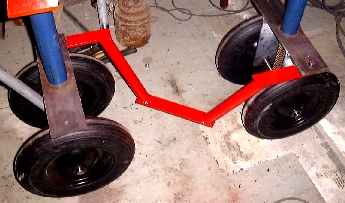

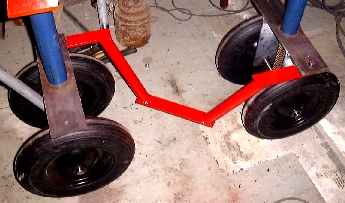

- 08.11.2003: Ontwerp en bouw wielstel. Wielassen: geharde as, 25mm diameter,

doorlopend per wielpaar. Vork uit plat 10mm dik. Kruisdisselbesturing uitgewerkt.

Vertikale draaiassen: 2" (60mm) koncentrisch met 6/4" buis (52mm):

lagering in Teflon. Duw- en trekveren te monteren. Wielen 38cm diameter.

- 09.11.2003: Stalen draagstruktuur afgelast. Kruisdissel met besparing bovenruimte

voor akku gelast. Houders ventielen op L profiel gespoten (Rood RAL 3000).

Trekveer gemonteerd in voorwielas (6mm draad, diameter 45mm, lengte 35 cm)

. Stuurstang met inox handgreep gelast. Ook hier veren voorzien zo dat de

handgreep wanneer niet in gebruik geen extra ruimte inneemt.

- De werkfotoos hierboven geven de details van de eerste atelierwerkzaamheden

vrij goed weer.

- 10.11.2003: Inkoop 2 nieuwe 12V akkus en lader voor 24V vrachtwagenakkus.

Draagstruktuur gelast voor akkus. De lader kan nu plaatsvinden onder de accus.

Het grote gewicht van <Puff>, met gemonteerde akkus, noodzaakte ons

tot de konstruktie van een loopkat voor de ateliertakel.

- 11.11.2003: Montage automatische akkulader onder akkukompartiment. Modifikatie

schakeling akkulader. Test voedingsschakeling. Schilderwerk ondergedeelte

chassis. (Zinkoxyde coating). Mail met printontwerp en schema binnengekomen

van Johannes Taelman. De export van Gerber plots schijnt nog problemen op

te leveren.

- 12.11.2003: Montage eerste puff-ventielen op rubber trillingsdempers. Boutjes:

Inox 4mm x 35mm, Hex-inbus. Montage akkuklemmen en verbinding met lader. Konstruktie

en montage zekeringenkast. (Zekeringen: 6 x 40A, 1x 3A, 1x 10A). Eindontwerp

uitvoering bedrading vermogenselektriciteit. Schema: zie engelse kommentaartekst

hierboven.

- 13.11.2003: Zoektocht naar een geschikte wals programmaschakelaar. Montage

42 puff-ventielen. Test 5V voeding. Montage massa kontaktstrips (omgebouwde

auto zekeringenkast). Software geschreven voor de berekening van de kwarttoonspijpjes.

De berekende lengtes zijn toegevoegd in de engelse tekst hierboven. Pijpdiameters

kunnen varieren van 40mm tot 10mm. De voeten kunnen konisch worden gedraaid

in kunststof op een metaaldraaibank.

- 14.11.2003: Montage 2e rij puff ventielen. Ongeluksdag. Enkele pyrex puffers

gebroken... PCB ontwerp verstuurd naar Digit printservice.

- 15.11.2003: Opzoekwerk naar de site van de fabrikant: http://www.airpot.com.

- 16.11.2003: Pyrex cilinders besteld bij Airpot corp.

- 17.11.2003: Koncentrische messingpijp besteld. Walsschakelaar besteld.

- 18.11.2003: berekeningssoftware ontworpen voor de kwarttoonspijpen en hun

mensurering voor messingbuis, wanddikte 1mm..

- 19.11.2003: 3 gebroken pyrex airpots van gebroken glas ontdaan.

- 21.11.2003: Nylon staaf ingekocht voor fluitkernen. Rem gemonteerd op voorwiel.

Draaibank besteld.

- 26.11.2003: PC boards geleverd voor PIC controllers. Start bestukking en

soldeerwerk.

- 27.11.2003: soldeerwerk PC boards

- 28.11.2003: Konstruktie inox draagplaat voor walsschakelaar , midi konnektoren

en CEE netstekker. Bedrading netstroom gedeelte en walsschakelaar. Montage

MIDI-konnektors (1 x IN, 2x THRU).

- 29.11.2003: Konstruktie draagstruktuur voor de zes processor boards. Soldeerwerk

processor boards. Uitwerking midi bedrading. Montage en afregeling 5V voedingsgedeelte.

- 30.11.2003: 18u kwazi ononderbroken bedrading gesoldeerd... Alle puffers

zijn nu verbonden met de Weidmueller konnektors en met de gemene plus van

de voeding. Voedingsaansluitingen aangesloten op zekeringenkast.

- 01.12.2003: Levering messing voor pijpwerk. Marc Maes: Bestudering materialen.

Levering eerste geprogrammeerde PIC controller voor board 1 door Johannes

Taelman. Bedrading logic power supply naar PIC boards voor eerste tests. Poging

tot herstelling met epoxy van gebroken puffer.

- 02.12.2003: Bedrading MIDI input en Thru. Levering Contimac metaaldraaibank.

Montage draaibank.

- 03.12.2003: Test midi input en buffering.

- 05.12.2003: Start konstruktie pijpen: Marc Maes. Vooras in gehard staal

afgedraaid op draaibank. Omega ringen gemonteerd. Konstruktie toegelicht in

interview voor BBC radio.

- 06.12.2003: Achteras afgedraaid op draaibank. Omega ringen gemonteerd. Puff

kan nu rijden. Nieuw assortiment metaalvijlen ingekocht voor konstruktie pijpwerk.

Circliptang gekocht.

- 07.12.2003: Bestaande verstorven rubberdempers afgesneden en vervangen door

viltkussentjes. Twee airpot's gelijmd met doorzichtig epoxyhars (Loctite 3430).

Kabelboompjes aangelegd.

- 08.12.2003: Levering IRL640 Power Mosfets. Verlijming reserve airpot met

Loctite 3430. Onderzoek fel witte LED's voor licht. Alle power mosfets ingesoldeerd.

Op de ontbrekende PIC controllers na, is het hart van <Puff> nu volledig

operationeel. Verder werk aan pijpen door Marc Maes.

- 09.12.2003: Start konstruktie lichten met felwitte LED's. Ontwerp stappenmotor

sturing voor lichtpositionering. Test elektronika op soldeersluitingen.

- 10.12.2003: Mapping 'eyes' changed. All controlls should be implemented

with the spare drivers on board 3: Weidmueller pins 0,1,2,8 each control a

phase of the stepping motor (pulsed operation), whereas pins 9 and 10 (ON/OFF)

controll the bright LED lights. This requires the midi note mapping to be

changed as: notes 49,50,51,52: motor phases and note 53,54: light switches.

- 11.12.2003: Konsole gelast voor stappenmotor oog-lichten. Bedrading stappenmotor

en lichten gelegd. Alle besturingen hiervoor komen voor rekening van board

3.

- 12.12.2003: levering 18F252 PIC controllers.Experimenteersessie kwarttoonspijpen

uit messing.

- 13.12.2003: Test board 1 with midi input: works fine but all notes are shifted

offset 1...

- 14.12.2003: PIC debug sessie met Johannes Taelman. Persistent probleem met

output 15 op de Weidmuellers... Experimentele set pijpen aangebracht ter evaluatie

van de aanslag.

- 15.12.2003: Prototype hoge pijp gemaakt in messing. Kernblok en inblaasvoet

in een enkel stuk. Atelier werk met Marc Maes en Johannes Taelman.

- 16.12.2003: Eerste publieke demo van het <Puff> projekt: bijna half

af... Stappenmotor en lampjes werken naar behoren. Enkele puffers doen het

nog niet en er zijn nog wat problemen met de mapping.

- 17.12.2003: hardware en mikrokode debug. Alles lijkt nu naar behoren te

werken. Alle zes PIC's zijn geprogrammeerd en de mapping lijkt te kloppen.

- 18.12.1003: Verdere test kode toegevoegd aan GMT in module g_gorgel.exe.

(source: puff.inc).

- 19.12.2003: Konstruktie pijpwerk in messing.

- 05.01.2004: vervolg pijpkonstruktie in messing door Marc Maes.

- 09.01.2004: Pijpkonstruktie Marc Maes

- 13.01.2004: Pijpkonstruktie: 7 pijpjes klaar. Voetsstukjes in roodkoper

ontworpen met bevestiging aan chassis.

- 14.01.2004: Tweede publieke demo: <GeroPuff> gedemonstreerd met Emilie

De Vlam.

- 19.01.2004: Pijpkonstruktie: 14 pijpjes klaar.

- 22.01.2004: Pijpkonstruktie: 16 pijpjes klaar.

- 23.01.2004: Pijpkonstruktie 19 pijpjes klaar.

- 25.01.2004: Pijpkonstruktie 24 pijpjes klaar.

- 29.01.2004: Levering nieuwe lastafel Welda.

- 30.01.2004: Levering massief roodkoper, 2m lengte 50mm diameter. Begin zagen

in plakjes van 10mm. Centeren op draaibank. Boren doorlaat 5.5mm en frezen

opzetkonus voor Airpot puffers. In te kopen: vingerfrezen in maten overeenkomstig

pijpbuitendiameters. Levering nieuw Argon gas.

- 31.01.2004: Alle 84 plakjes roodkoper afgezaagd. Draaiwerk roodkoper pijpvoeten:

alle konussen onderzijde afgedraaid. Vlak draaiwerk voor pijpen 16mm en 18mm

afgewerkt. In te kopen: boren met morsekonus MK2, diameters 16mm, 18mm, 20mm,

24mm, 26mm.

- 01.02.2004: 9 pijpvoeten ingefreesd op 20mm met vlakke houtboor (vlinderboor)

in vast gedeelte draaibank (met koelvloeistof). Ridgid metaalzaag op gelaste

zaagtafel gemonteerd.

- 02.02.2004: Bevestiging pijpen op chassis ontworpen. Draaiwerk pijpvoeten

diameters 28,24,22mm, telkens 9 stuks afgewerkt. Nog te doen: diameters 30,32,

26 en 14mm.

- 03.02.2004: Draaiwerk pijpvoeten 26, 30 en 32 mm uitgevoerd met vlinderboren.

Marc Maes: enkele extra pijpjes afgewerkt.

- 12.02.2004: Pijpwerk Mark Maes. 29 pijpjes afgewerkt. Puff operationeel

gemaakt binnen M&M orkest.

- 15.02.2004: Puff partij geimplementeerd in Descent, als akt in Technofaustus.

- 23.02.2004: Werksessie pijpen Mark Maes.

- 24.02.2004: Werksessie pijpen Mark Maes. 47 pijpen afgewerkt. Sokkels voorzien

van inslagnummers.

- 26.02.2004: Soldeerproeven pijpen met hete lucht bunsenbrander. Vijf pijpen

gesoldeerd.

- 27-28.02.2004: Soldeerdagen. Alle 46 reeds afgewerkte pijpen gesoldeerd.

Basis plaat met 2.8mm Zilver-Tin (AgSn) soldeer, labium naad met SnPb soldeer

0.6mm.

- 29.02.2004: soldeertechniek gedokumenteerd

in kursus...

- 01.03.2004: pijpvoeten van inslagnummers met de (midi) noten voorzien.

- 04.03.2004: zaagwerk laagste 9 pijpen (vanaf midi noot 55): Messing buis

32/30. Bouwplan pijpvoeten:

- 05.03.2004: laagste 9 pijpen gemonteerd en gesoldeerd.

- 06.03.2004: pijpen voor noten 59.5 tot en met 63.5 gebouwd, gemonteerd en

gesoldeerd. Onderdelen voor pijpen 64 tot en met 68 gedraaid, gezaagd en gefreesd.

- 07.03.2004: Extra pijp voor noot 88 gebouwd. Pijpen 64-68 afgewerkt. Voetblokken

voor diameter 26/24 gedraaid, gefreesd en gevijld. Messing buis 26/24 blijkt

niet geleverd... Er blijven nog 9 pijpen af te werken. Op de foto hieronder

zijn de inwendige onderdelen van de pijpvoeten te zien. Op de bovenste rij

liggen de stoppen voor het uiteinde van de pijpen. Op de onderste rij, de

pijpbasissen.

- 08.03.2004: Zijsteunen pijpwerk ontworpen.

- 09.03.2004: Pijpje 96.5 gebouwd en gesoldeerd. Zijsteunen voorzien van oranje

lichten: midi mapping op noten 104 en 105. De zijsteunen worden gemonteerd

op trillingsdempers M10, 40mm diameter. Test software g_gorgel.exe in GMT

aangepast.

- 10.03.2004: 24V/15W bajonet lamp geplaatst in lampvoet voorkant. Koperen

voetstukken gedraaid diam.41mm, hoogte 13mm voor plaatsing messing profielen

uiteinde.

- 11.03.2004: Schilderwerk: rood en zwart.

- 12.03.2004: Bevestiging schakelingen op chassis. Bestelling betere remschoenen.

Puf 96.5 uitgebrand... (Stuk Sebastian Bradt).

- 13.03.2004: Herstelling noot 96.5: hele werkdag... (Mosfet doorgebrand,

spoel uitgebrand, Airpot gebarsten...). Nieuwe airpot gebouwd uit chroombuis

(uitgedraaid), met zuiger uit aluminium. De velo scaling in de PIC's moet

gewijzigd worden. Bereik 1 to 20ms lijkt ruimschoots voldoende.

- 16.03.2004: Puff gedemonstreerd aan Christian Wolff. Achteraf, ongeval bij

afrijden Puff van hellend vlak in tetraederzaal vanwege de nog niet vast gemonteerde

pijpen: pijpen omgedonderd als een kegelspel met breuk in 5 pijpen voor gevolg.

Opnieuw gesoldeerd.

- 23.03.2004: try out met 'Quadrada Vectorial'. Voorlopige pijphouderlat gemonteerd

in staal.

- 25.03.2004: Levering 26/24 messing buis. Ontbrekende 9 pijpen verder afgewerkt.

Messing T-profiel gezaagd en bewerkt voor vasthouder pijpwerk. Definitief

stemwerk kan beginnen...

- 26.03.2004: Werksessie Godfried & Marc: Pijpen 55-72, kromatische reeks

gestemd en dichtgessoldeerd met zilver. Rem ontwerp gewijzigd: nu met kogelgewricht

op M12 schroefdraad. Opgelet: de bouten (messing) waarmee de pijphouder vastzit

zijn 5/8", engelse schroefdraad. Vastzetten met vleugelmoeren in messing.

Niet verwarren met M10. Pijpreeks 73 - 78 heeft wellicht oortjes nodig ter

verlaging van de grondtoon. (Mensuurfout!)

- 27.03.2004: Pijpen 55-75,5 gestemd en stoppen gesoldeerd. Pijp 73.5 volledig

nieuw gemaakt. Transportbeveiliging ontworpen.

- 28.03.2004: Grof stemwerk pijpen 75 tot 80 (kwarttoons) en tot 96, kromatisch.

Enkele pijpen opnieuw gebouwd, wegens mensuurprobleem. Nieuwe rem gemonteerd.

- 29.03.2004: Pijp 73 (24/22mm) volledig opnieuw gebouwd (eerste versie gaf

teveel ruis). Ringbeugels gezaagd voor de laagste 9 pijpen.

- 30.03.2004: Verder stemwerk met Marc Maes. Rubberbanden voor bevestiging

pijpen verbeterd. Viton ringen 1.78mm dik, diameter 15.6mm, Shore hardheid

70, rond spoelkernen aangebracht ter demping van de aanslag. Pijpklemrek voor

transport gebouwd in hout.

- 31.03.2004: verstevigingsbeugels gemaakt voor alle pijpen tot en met diameter

20mm. Eerste verpakkingstest: Puff klaargemaakt voor transport naar Parijs.

- 01.04.2004: Puff naar Parijs...: Exit festival. Schitterende performance

van <GeroPuff> met Emilie De Vlam.

- 05.04.2004: Puff terug uit Parijs.

- 09.12.2004: Mosfet voor noot 93 doorgebrand, door teveel overlappende repeats

met hoge velocity waarden... Hersteld.

- 07.02.2005: Observatie okkazionele oscillatieproblemen van de akkulader.

- 15.02.2007: De transfo in de akkulader (franse makelij...) begint vervaarlijk

veel te zoemen. We zoeken een alternatief voor de lader.

- 08.04.2007: Nieuwe automatische 24V lader besteld bij Farnell.

- 12.04.2007: Nieuwe lader geleverd. Tests.

- 16.04.2007: Montage nieuwe automatische 24V lader. Type: EA-BC524-11RT,

Elektro-Automatik, Viersen, Deutschland. De akku's blijken echter totaal versleten

te zijn... Ook de antieke nieuw gemonteerde voltmeter blijkt niet te werken.

- 17.04.2007: de ventilator van de nieuwe lader blijkt nu weer problemen op

te leveren... Hij blaast periodiek. Voltmeter hersteld: de draadgewikkelde

precisieweerstand (uit 1938...) was gekorrodeerd en stuk. We vervingen hem

door een modern 0.1% metaalfilm exemplaar van 4999 Ohm. De draaispoelmeter

zelf is een milliamperemeter met een schaalbereik van 10mA. Een alternatief

voor de Puff voeding zou zijn: een Siemens Sitop 24V/20A SMPS voeding met

konvektiekoeling met 500mF aan bufferelkos... We bestelden alvast bij Farnell

enkele 150mF/40V elkos (ca.75 Euro per stuk...) voor de ombouw van de voeding.

Dit blijkt evenwel heel wat goedkoper dan om de drie jaar twee nieuwe 100Ah

akkus.

- 18.04.2007: Verdere herberekening voeding.

Layout plan nieuwe voeding uitgetekend en ingepast in bestaande laskonstruktie.

Layout plan nieuwe voeding uitgetekend en ingepast in bestaande laskonstruktie.

- 20.04.2007: Nieuw inox subchassis gebouwd voor de voeding. Zwaailicht ondersteboven

onder de robot gemonteerd. De nokkenschakelaar die we hadden - eigenlijk een

ster driehoekschakelaar- blijkt onbruikbaar in de nieuwe kontekst, tenzij

we er alleen de primairen mee zouden schakelen. We beslisten het gehele akku-gedeelte

met lader uit het ontwerp te schrappen.

- 21.04.2007: Afzonderlijke netspanningsschakelaar gemonteerd. De paneelmeter

-voltmeter- wijst nu de spanning op de elkos aan. De zwaailicht schakeling

is nu aangesloten op konnektor 4b. Pic assembler kode aangepast aan nieuwe

mapping.

- 22.04.2007: Nieuwe PIC gemonteerd en getest: werkt o.k. Harley-Davidson

lamp gemonteerd aan de low-side van Puff: nieuwe fitting gemonteerd en kogelkopverbinding

gesoldeerd op de messing drager. Lampje: 24V/10W halogeen.

- 31.08.2008: Upgrade doorgevoerd van de GMT testkode.

- 27.05.2010: Puffs right eye needs a checkup. It does not turn on anymore...

- 18.08.2010: Pipe 84.5 needs retuning and soldering of its endcap.

- 01.10.2010: Revision of the eye motor movement and the eye's themselves.

We are considering using a dedicated PIC processor for this task. Movement

sensing can than be integrated as well.

- 03.10.2010: Assembly of a modified midi-hub board (version 3) to use as

a controller board for the eye movements and some sensors. Construction of

a mounting plate for the Pepperl+Fuchs end position sensors. Construction

of a mounting system for the PIR sensors.

- 04.10.2010: Further mounting works. Final assembly of the PIR sensor carrier.

First experimental mounting of the Pepperl+Fuchs proximity sensors. Note that

these operate on 24V DC and hence need an attenuator network for interfacing

to our PIC board.

- 05.10.2010: Wiring of the midi hub board used:

- 06.10.2010: First debugged version flashed into the motor control board.

This be version 1.0

- 13.10.2010: Tests in GMT seems ok Some adjustments on the sensors required.

- 09.11.2010: Code in motor control board improved. Now version 1.3. Some

bugs in the interpretation of the PIR signals removed. Sampling rate for the

PIR's lowered.

- 16.11.2015: Cleanup and check of power supply. Puff still works fine.

- 27.08.2021: <Puff> goes to the SMAK museum for all of the month september.

- 01.09.2021: Dust removed from the cicuit boards.

- 02.09.2021: Opening of the robot exhibition at SMAK.

- 27.09.2021: <Puff> returned from SMAK. It has been playing for 25

days continuously. Some solenoid/pump assemblies found to be loose on the

back row.

- 14.09.2023: <Puff> joins the robot orchestra in its trip to the Deutsche

Oper Berlin. The 'Zeroth Law' production by Gamut Inc. was performed in 27,

28 and 29th of september 2023 at the Tischlerei. All performances were fully

sold out.

- 02.10.2023: <Puff> returned heavily wounded from its trip to Berlin.

Many of the blow-out nipples on the pumps found broken off by heavy shaking

and improper securing during transportation. This will be a complicated repair

involving some preparatory study work. However, the electronics and the valves

themselves seem all to work fine.

Afmetingen & andere technische specifikaties:

- hoogte: 1480mm (gemeten aan de langste pijp)

- breedte: 1500mm (exakt)

- diepte: 400mm (exakt)

- gewicht: ca. 200kg (na te wegen)

- maximale geluidsdruk: te bepalen

- Vooraleer de robot aan te schakelen, verifieer de stand van de hefboomschakelaar:

deze moet op off staan en de door de voltmeter aangewezen spanning moet kleiner

zijn dan 5V. Pas onder deze voorwaarden mag met de wipschakelaar onder het

voedingsgedeelte, de netspanning worden ingeschakeld en daarna pas, de hefboomschakelaar

in de aan-stand gezet. Bij uitschakelen, steeds eerst de hefboomschakelaar

in de off-stand zetten en dan pas de netspanningsschakelaar uitzetten.

- stemming: kwarttoons vertrekkend van een diapason van La = 442Hz

- tessituur: midi 55 tot en met 96 in kwarttonen. Bij overblazen 55 tot 115.

- zwaailicht: gemapt op midi noten 100, 101, 102 (msb-lsb, 3 bits snelheidskontrole)

- data-poort: Midi port. (hardwired to listen to midi channel 13 only)

- Transport: een vrachtwagen met laadlift is noodzakelijk. De pijpen moeten

beschermd worden met de daarvoor speciaal voorziene bekistingen. Deze worden

vastgeschroefd op de messing pijphouder profielen met de bijhorende vleugelmoeren.

- Verzekeringswaarde (produktiekost): 55.000 Euro.

Design, research en staalkonstruktie: dr.Godfried-Willem

Raes

Atelier medewerkers:

- Bert Vandekerkhove (montage en requisitering)

- Marc Maes (messing pijpkonstruktie, stemming en intonatie)

- Johannes Taelman (PIC microcontrollers)

- Kristof Lauwers (test kode in GMT)

- Moniek Darge (inkleuring)

Last update: 2023-10-11

by Godfried-Willem Raes

Maintenance information:

- Light bulbs used:

- back side brigth orange light: Halogen Lamp, type JC G4, 24V - 10W (110

Lumen, 2000h)

- front side dark orange light: Halogen Lamp, type JC G4, 24V - 10W (110

Lumen, 2000h)

- Rotary light: Halogen Lamp 24V/ 70W, mapped on midi notes 100,101,102

(msb-lsb)

- LED spotlites inside chassis: 2 x 12V, mapped op midi note 103

- 1W LED Red mounted under motor control board, mapped on midi note 120

- Eye lights: 1W power LED. Left eye mapped on midi note 121, right eye

on midi note 122

PC-board layout:

The hefty electrolitic capacitors used as high current buffers in the power

supply are rated as 'long life'. That seems to mean a guaranteed lifetime

of 20000h. So, in continuous operation one can expect these components to

fail after two and a half years... If replaced, they have to be rated 150mF

each at 40V dc. They are fixed to the chassis with M12 nuts. The negative

pole is connected to the can and to the nut/bolt.

Detailed steering details for the rotating flashlight:

| note 100 |

note 101 |

note 102 |

current |

power |

| off |

off |

off |

0 |

0 |

| off |

off |

on |

1.08A |

26W |

| off |

on |

off |

1.37A |

33W |

| off |

on |

on |

1.76A |

42W |

| on |

off |

off |

1.89A |

45W |

| on |

off |

on |

2A |

48W |

| on |

on |

off |

2.1A |

50W |

| on |

on |

on |

2.2A |

53W |

Eye & Motor mechanism (rev. 10.2010)

2 PIR-STD passive infrared movement sensors (Hygrosens. http://www.hygrosens.com).

Mounted in a thick aluminium profile with epoxy resin. The power supply voltage

for these is taken from the logic +5V.

2 Pepperl+Fuchs proximity sensors (NBB2-V3-E2)

Midihub board Version 3, with modifications for sensor inputs. Pic processor

18F2525. Firmware written in Basic and compiled with the Proton+ compiler

under MPLAB. Circuit diagram.

Pic source code in assembly language

(Eye control PIC) Version 1.1

Pic source code & downloads for high

resolution pictures

Layout plan nieuwe voeding uitgetekend en ingepast in bestaande laskonstruktie.

Layout plan nieuwe voeding uitgetekend en ingepast in bestaande laskonstruktie.