|

<HarmO>

|

|

Research

project on the development of new tools for musical expression at

the University College Ghent

Godfried-Willem RAES

2009/2010

|

Technical Description

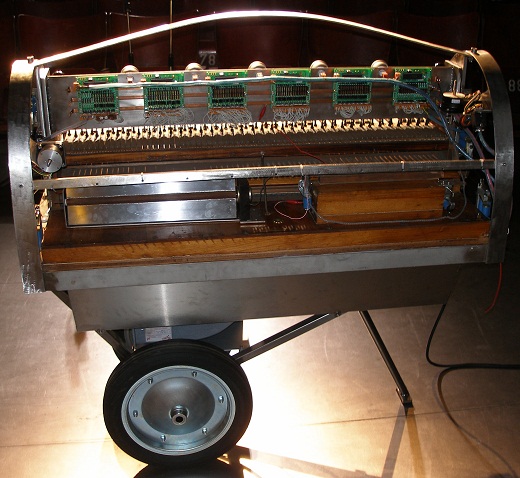

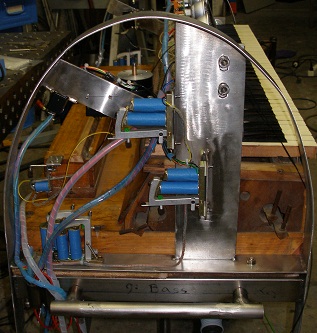

A computer controlled 6-octave reed organ with touch control, swells and individual

registration. The starting point for this construction was an old Emile Kerkhoff

(1887-1956) suction reed organ, of which we only kept the reeds and the key

springs. A new electric compressor was added (a small Laukhuff Ventola, rated

for 80mm H2O pressure (800 Pa) and 3000 l/min) replacing the bellows. The instrument

has 4 sets of reeds for the bass side and 4 sets of reeds on the treble side.

In addition it is equipped with 1 octave (13 reeds) of reeds for a subbass.

These sound the notes 12 -24.  The

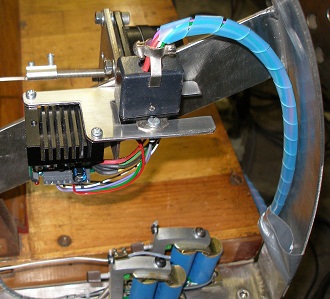

picture shows the note valves for this subbass with the box resonator removed.

Taking the registers into account, the real sounding ambitus ranges from midi

note 12 to 113, or an impressive eight and a half octaves!

The

picture shows the note valves for this subbass with the box resonator removed.

Taking the registers into account, the real sounding ambitus ranges from midi

note 12 to 113, or an impressive eight and a half octaves!

Two swells are provided, as well as a reflective tremulant mechanism. In total

the organ has 305 reeds. Although the instrument is signed and labeled Kerkhoff,

we have doubts with regard to the real builder. It may very well be an American

made Beckwith reed organ (Type: Grand Orchestral Action G, 6 octaves 18 stops).

Embossed in the back of the triplex soundboard, it carries the series number

54938.

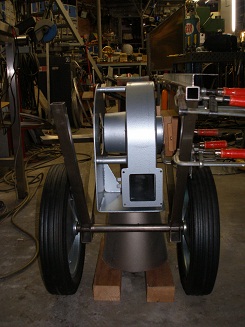

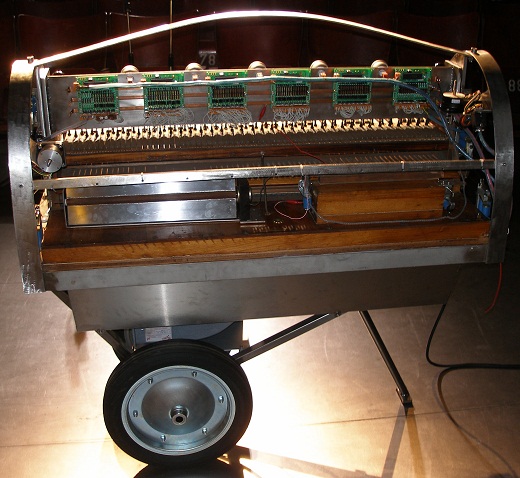

As usual in our automated instrument designs, we designed a sturdy welded

frame made in stainless steel for the entire magnet and electromechanical assembly.

As a reminder: we favor AISI304 stainless steel not only for its visual qualities

and freedom of maintenance, but also because it is a nonmagnetic material. Other

than in our first robot reed organ, here we decided to leave the original keyboard

in place. As a consequence, it becomes possible to play the organ in the traditional

way even in combination with automated playing. For registration and expression

control however, we did not foresee a manual alternative. We used tubular solenoids,

20mm in diameter, to activate the keys here serving as levers to reduce the

required force to push the pallets down. This saved us the work of replacing

all pallet springs with lighter ones as we did in <Harma>. Since the magnets

are wider then the distance between keys/pallets (13.5mm), we had to mount them

on alternating rows. This became another reason for not activating the pallets

directly. The eight registers are each divided in a bass and a discant unit.

So we provided also control for these 8 registers. Although we first wanted

to implement this using solenoids with variable voltage , such that gradual

changes ('expression') would become possible, some experimentation revealed

that the small benefit was not worth the effort and increase in complexity.

Gradual opening of the register shutters did just not produce the expected result.

However, gradual opening of the dynamic shutters appeared to be an interesting

feature worth implementing. Our first attempt using soft shift linear solenoids

to this end were not successful because these solenoids did not produce enough

pulling force to guarantee a smooth action. Therefore we finally decided to

use linear stepper motors with a threaded shaft. This approach makes a smooth

action possible at the expense however, of some extra noise caused by the audible

stepping frequency. Although this mechanism is relatively low in action, the

big advantage of it is that it draws no current to keep position, but only so

on movement. The whole traject from closed to fully opened takes about 500ms.

The design of the tremulant was quite adventurous in some respects. At first

it appeared that we had about four options:

- 1. Leaving the original pneumatic motor driven mechanism in place and switching

it on/off using a solenoid.

- 2. Using a 35mm Laukhuff pallet valve mounted right on the whole in the

windchest.

- 3. Using a softshift solenoid driving a conical valve.

- 4. Using a solenoid driven bellow to modulate air pressure.

The first solution, although the easiest one, suffers from the fact that the

speed of rotation of the tremulant becomes a function of wind pressure and

thus cannot be controlled independently. Also the mechanism tends to be shaky,

fragile and causes some noise.

The second solution - very easy to implement- works pretty well but suffers

from a rather square wave like behavior. Also, when the valve is opened, the

air flowing in makes quite some noise.

The third solution requires the construction of a very well machined conical

valve with a traject of 10 mm. Its operation becomes as smooth as one wishes

since it becomes possible to steer it with a very low frequency sine wave

of variable amplitude. Of course other wave forms would lead to different

amplitude modulation envelopes.

The fourth solution leads to the best results. When a large loudspeaker -a

powerful woofer- is used as a bellow, the pressure in the windchest can be

modulated even at very fast rates. However, the compressed volume should be

in a reasonable proportion to that of the entire windchest, thus dictating

the use of a speaker with a diameter of some 30 cm. This would make the instrument

much larger than what we had in mind. The same size argument does apply to

the solution using a solenoid driven bellow.

Softshift

tremulant.

Softshift

tremulant. - As soon as we tried the second and third options (shown on the picture above),

we discovered that neither of them worked. Mounting the original pneumatic

mechanism, however worked fine... Clearly we made a fundamental mistake in

the way we understood the function of the tremulant. Rather than working on

modulation of the air pressure in the windchest -as usual in pipe organs-

, it worked merely on acoustic reflection of the sound on the large cardboard

blades of the rotator. In fact it makes use of the Doppler effect to create

a slight but real vibrato. Therefore we had to redesign the mechanism completely,

and since we wanted to have autonomous control over the modulation frequency,

we needed to build a reflector mechanism driven by a variable speed motor.

The use of a simple low power stepper, as used for the vibrato drivers on

our <Vibi> robot came into our mind, as these run really silently..

The radial compressor used for the wind supply is equipped with a wind regulating

slide mounted on the inlet of the windchest. This slide can also be controlled

and allows for faster wind pressure changes than can be achieved by regulation

the rotation speed of the motor. This slide is driven by a stepping motor coupled

to a dented belt. In the midi implementation this slide is mapped on the standard

windcontroller (nr. 1), whereas the motor speed is mapped on controller 7, the

general volume controller.

The note range of the instrument is 29 to 101 expressed in midi note commands.

Taking into account the registers (32', 16', 8', 4' and 2'), the real range becomes

17 to 113. Although in the design phase we considered making the instrument fully

polyphonic, we finally decided to limit polyphony on this automate to 32 notes.

For a full 73 note polyphony would have implied the construction of a hefty 45

A / 12 V power supply. Even though possible, the compressor would never have enough

wind to make all the reeds sound. Thus we decided to forsake full polyphony. Even

at 32 notes held simultaneously (particularly in the bass...) the wind supply

is barely powerful enough. The finished instrument has following dimensions: depth

490mm, width 1165mm, height 1000mm. The weight is ca. 60kg.

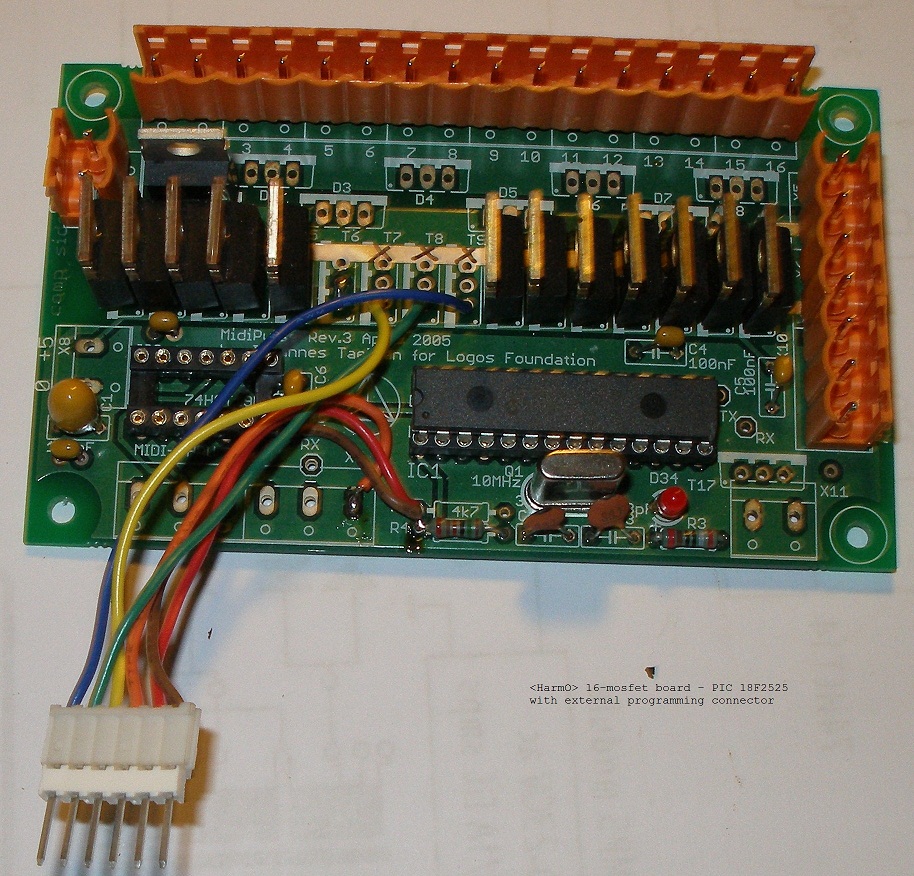

<HarmO> is controlled by no less than 13 PIC microcontrollers (6 for

the notes and the registers, 3 for the linear stepper motor controllers, 2 for

the compressor motor, 1 for the lights, the motor control signals and the tremulant)

and takes midi input directly. Of course the instrument can play standard midi

files. <HarmO> was designed from the beginning on with velocity control,

based on precise timing of an initial high voltage pulse to activate the note

solenoids. The effect of velocity control or touch sensitivity is of course

by far less effective than it is on our player piano or on the organs equipped

with conical windchest valves such as <Bomi>.

The speed wherewith the valves open in a reed organ being generally much faster

than the rather slow build up of a sound from the reeds. However, any touch

sensitivity a reed organ played by a human might have, is also implemented and

at least surpassed in this robot. In fact in this robot reed organ, we realized

a major improvement over the first similar but smaller reed organ robot,

<Harma>. The fact that this robot is tuned to 440Hz, rather than the

435Hz on <Harma>, makes it more suitable for integration in our robot

orchestra.

In 2015 we added a new feature to the wind regulation mechanism: it now is

'intelligent' in that it will automatically adapt windflow to to notes affectively

played as well as to registers drawn and volume setting requested. It is no

longer possible for users to make the mistake to let the motor turn at full

speed (high volume setting) when no notes are being played. The firmware for

the wind motor control was revised a few times, the last revision is dated 27.11.2022.

The circuit overview looks like this:

Circuit details as well as a very detailed building log can be found in the

service manual at the very end of this page.

Design and construction:

Collaborators:

- Kristof Lauwers, GMT coding

- Yvan Vander Sanden

- Moniek Darge

- Troy Rogers, construction assistence (Fullbright PhD student, Virginia University)

- Irs.Johannes Taelman, microcode PIC's.

Nederlands

<HarmO>

Tessituur: 29 (Fa) - 101 (Fa) [ 6oktaven ]

Hiervoor werd uitgegaan van een oud harmonium -volgens

het label althans- gebouwd door Emile Kerkhoff, een ambachtelijk wat aan lager

wal geraakte orgelbouwer gevestigd in Brussel. De gehele bouw lijkt als twee

druppels water op een Beckwith instrument, type 'Grand Orchestral Action

G, 6 octaves 18 stops'. Wellicht heeft Kerkhoff niet veel

meer zelf gebouwd dan de kast rond het instrument... Het instrument is voorzien

van acht onafhankelijke reeksen doorslaande tongen en werkt met zuiglucht, zoals

het gros van de naar Amerikaans model gemaakte 'reed organs'. Vier registers

voor de bas en vier voor de diskant. Als extra is het harmonium uitgerust met

een subbasregister bestaande uit 13 rieten geplaatst in een afzonderlijke bakje

dat als resonator dienst doet. Rekening houdend met de registers, strekt de

eigenlijke muzikale tessituur van dit instrument zich uit over acht en een half

oktaaf (12-113). De balgen en windlade verwijderden we integraal en werden vervangen

door een kompressor met motorbesturing, een Laukhuff Ventola zuigblazer. (3000

l/minuut, bij -80 mm H2O druk). Daar dienden we wel een goede geluidsdemper

voor te ontwerpen want geruisloos zijn deze Ventola blazers bepaald niet...

De kracht vereist om de paletten rechtstreeks, dus zonder

de hefboom gevormd door de toets en het eigen gewicht van de toets, in te drukken

maten we als 2.45 Newton (250 gF). Bij de bouw van <Harma>, ons eerste

robot harmonium, hadden we de kracht van de veren ongeveer gehalveerd teneinde

kleine Laukhuff elektromagneten te kunnen toepassen. Het nadeel van dat opzet

was dat het instrument makkelijk neiging heeft tot lekken wanneer druk in de

lade wordt opgebouwd zonder dat noten gespeeld worden. Dit euvel wilden we hier

vermijden. Buisvormige elektromagneten met een diameter niet groter dan 13mm

(wat vereist zou zijn om de magneten uitgelijnd met de paletduwers te plaatsen)

en een dergelijke kracht (2.45 N) worden niet gefabriceerd. Daarom maten we

de kracht nodig om de toetsen in te drukken en kwamen uit op 1.2 tot 1.5 Newton.

Heel wat minder dus, wat uiteraard te wijten is aan de werking als hefboom en

aan het eigengewicht van de toetsen.

Hartafstand tussen de bedieningspallen voor de rieten

was 13.54mm, waardoor we de magneten om en om (in twee rijen) dienden te monteren.

Wanneer we de bedieningsmagneten om en om monteren, mogen ze dan hooguit 27mm

breed zijn. De gebruikte types zijn 20mm breed. Voor deze montage plooiden we

een inox plaat van 2 mm dikte in een assymetrische U-vorm. In de onderzijde

daarvan werden de 73 gaten voor de montage van de elektromagneten geboord. Om

de automaat goed te kunnen afregelen, werd de gehele elektromagnetendrager zo

gemonteerd op de zijdelingse steunen, dat de hoogte ligging heel nauwkeurig

kan worden ingesteld.

De registers zijn telkens gedeeld in bas- en diskant.

Voor de automatisering daarvan gebruikten we elektromagneten met dubbele spoelen

van de firma Laukhuff. Er zijn 4 registers aan de baskant en 4 aan de sopraankant.

Daarbovenop komt nog het subbasregister. Voor de automatisering van de zwelkasten,

werden twee lineaire stappenmotoren van Nanotec toegepast. De toepassing van

soft-shift lineaire magneten hadden we oorspronkelijk voorzien, maar daarvan

dienden we uiteindelijk af te zien vanwege de te geringe kracht die deze komponenten

kunnen leveren (8 tot 13 Newton, terwijl we eigenlijk meer dan het dubbele nodig

bleken te hebben). Bovendien vormde ook het vermogen nodig om een bepaalde positie

aan te houden (21 Watt) een bezwaar. Lineare stappenmotoren met een schroefgang-as

houden hun positie wanneer ze volledig stroomloos worden gemaakt. De snelheid

van deze mechanismen is echter heel wat lager dan bij soft-shift magneten. Het

hele trajekt met de lineaire motoren neemt ca. 500ms in beslag, terwijl dit

bij toepassing van soft-shift magneten slechts 45ms zou duren.

De radiale kompressor is voorzien van een regelschuif,

gemonteerd aan de inlaat van de windlade. Deze regelschuif werd eveneens geautomatiseerd

en daarvoor ontwierpen we een mekanisme met een stappenmotor en een getande

riem. Hierdoor wordt een snellere regeling (ca. 200ms voor het gehele trajekt)

van de winddruk mogelijk dan wat voorzien is via sturing van het toerental van

de motor zelf. De windregelschuif werd gemapt op midi kontroller nr.1, terwijl

de motor snelheid gestuurd kan worden middels midi kontroller 7.

Voor de elektronische besturingen van de toonkleppen

gebruikten we onze eigen en beproefde ontwerpen voor muziekautomaten, meer in

het bijzonder, de schakelingen ontwikkeld voor onze player pianos en later in

talloze andere robots toegepast. Daardoor kon ook aanslaggevoeligheid worden

geimplementeerd. Hoogst ongebruikelijk voor een harmonium, maar we hadden het

al eerder gedaan bij de bouw van <Harma>, <Qt>, <Bomi> en

<Bako>. <HarmO> kan rechtstreeks via midi zowel als UDP/IP worden

aangestuurd. Ook de winddruk is heel nauwkeurig regelbaar, waardoor crescendos

perfekt mogelijk zijn. Dit effekt is trouwens op een andere wijze ook te bereiken

door gebruik te maken van de beide eerder genoemde zwellers.

Een klein grapje hebben we onszelf bij de bouw van deze automaat toch gepermiteerd:

een klopgeest werd ingebouwd... Ook die klopgeest kan via midi kommandos aan

de praat worden gebracht.

Niet minder dan dertien mikroprocessoren, elk voorzien

van eigen en onderling verschillende firmware, staan in voor de interne besturingen

van de diverse onderdelen van deze robot.

Tot de revizie die <HarmO> onderging in 2015 dienden

komponisten die voor deze robot wilden schrijven er terdege mee rekening houden

dat de winddruk geregeld moest worden in funktie van de gewenste dynamiek enerzijds,

maar ook in funktie van het luchtverbruik. We dienden er telkens wee op te wijzen

dat het luchtverbruik voor lage tonen heel wat groter is dan voor de hoge. De

vroeger meest voorkomende fout in midi bestanden, bestond erin de druk bij aanvang

van de track of partij in te stellen op een vaste waarde. Hierdoor echter werd

druk opgebouwd zonder rekening te houden met het al dat niet spelen van tonen.

Dit leidde niet alleen tot volkomen overbodig lawaai van de motor, maar ook

vaak tot lekken in de toonkancellen. De enige goede metode bestond erin, na

het inbrengen van de muzikale partij, de windkontroller instellingen (nr.7)

voor de gehele track te bepalen in funktie van de notentekst en de gewenste

dynamiek en expressie. In 2015 evenwel voegden we een microprocessor toe in

<HarmO> die de motorsturing volledig afhankelijk maakt van het effektieve

luchtverbruik en van het gewenste volume. Een aantal extra midi controllers

werden aan de implementatie toegevoegd. De meeste recente upgrade van de firmware

voor deze functie werd uitgevoerd op 27.11.2022.

|

Tech-Specs -----------------------------------------------Technische

specifikaties:

Aanvang bouw: september 2009

Operationeel sinds december 2009, volledig

afgewerkt begin 2010.

Laatste software upgrade: 27.11.2022

Size------------------------------------------------------------------------------Afmetingen

van het afgewerkte instrument:

- diepte: 500 mm

- breedte 1165 mm

- hoogte 1080 mm

- Gewicht: 115 kg

Power--------------------------------------------------------------------------------------------------------Stroomvoorziening:

Insurance value (for organisors):

25.000 Euro

Rental / concerts:

This instrument can be rented from Logos Foundation. A technician from

logos will allways accompany the automate. The tariff is 750 Euro a

day. Transportation is possible with a normal not too small liftback

car.

|

|

Midi

Implementation

Midi Implementatie:

The midi channel for <HarmO> is set to

9 (if counting channels from 0, otherwise, 10)

- Note ON/ Note Off notes 29 to 101 with velocity byte. (real sounds:

17 - 113) The velocity byte steers the speed wherewith the keys are

depressed. This has no effect on sound volume but affects legato versus

staccato playing.

- The ghost beaters are mapped on midi notes 0

and 1 and have velocity implemented. Note off is not required here.

- 1: Wind controller: 176 + channel, 1,

value (This controls the wind slide) The full traject takes some 250ms

to complete. This controller can be used for moderately fast modulation

of the amplitude within the limits set by controller 7. The usefull

traject goes from 24 to 100.[temporarely disabled

- 2021]

- 7 : Volume controller: 176 + channel,7, value (This controls the frequency

for the compressor motor and thus the maximum windpressure). The default

value for wind pressure value is 64. (Motor frequency 44 Hz)

- 66: Motor ON/OFF: 176 + channel, 66, value (0 or any value between

1 and 127). The green LED on the motor controllerboard will lite up

when controller 66 is on.

- 67: One-shot controller used to reset the motor

controller if it stopped working due to a failure. [for expert use only].

To restart the motor after this acknowledge, controller 101 can be used.

- 68: Windpressure mode of operation. When set to 0 (the default] the

motor control will be 'intelligent', that is, motor speed will automatically

adapt to the register settings as well as to the notes played. When

set to 1, the motor will run only at a speed determined by controller

#7 (volume controller). As a warning, the blue led on the motor controller

board will light up when this controller is set to any other value than

zero.

- 69: not implemented in HarmO

- Registration makes use of controllers:

- 70: bass reg 1 (On/Off) ( 2' cor anglais, frontal swell ) (real notes

53 - 76)

- 71: bass reg 2 (On/Off) (8' diapason, frontal swell ) (real notes

29 - 52)

- 72: bass reg 3 (On/Off) (16' bourdon, back swell ) ( real notes 17

- 40)

- 73: bass reg 4 (On/Off) (4' principal , back swell) (real notes 41

- 64)

- 74: sub bass register (On/Off) (32' real notes 12 - 24)

- 75: treble reg 1 (On/Off) (4' cremona, frontal swell) (real notes

65 - 113)

- 76: treble reg 2 (On/Off) (8' forte, frontal swell) (real notes 53

- 101)

- 77: treble reg 3 (On/Off) (16' clarinet, back swell) (real notes 41

- 89)

- 78: treble reg 4 (On/Off) (8' oboe, back swell) (real notes 53 - 101)

- 79: frontal swell (0-127, value 0 closes the shutter completely, so

pp. )

- 80: back swell (0-127), value 0 closes the shutter completely, so

pp.)

- 82: Tremulant (0-127) analog output voltage for doppler tremulant

speed control. (0- 18Hz) Note that the tremulant is only effective for

notes higher than midi 67. Also for best effect the back swell has to

be opened and any one or more of the register controllers 77 and 78

have to be selected.

- 100: selection of lookuptable for the airflow

control This controller is for research purposes only. The default value

is 16. This value should only be set to different values by users that

are thoroughly familiar with the coding in the firmware of the motor

microcontroller. Unthougthfull use can crash the microcontroller. Check

the firmware in HarmO_motor.bas

before using this.

- 101: This controller, for expert use only, switches

the motor controller on or off, irrespective of the setting for controller

66. It can be used after an error occurs with the motor controlller

that is reset with controller 67, to switch the motor back on without

resetting other controllers.

- 123: AllNotesOff: 176 + channel, 123, 0. No controllers are affected

by this command.

- Program change command (192 + channel, patch)

Program changes with patch numbers between 122 and 127 let users select

different lookup tables for the velocity scaling of this instrument.

The lookup tables can be changed using sysex commands. Pincode: horm.

The optimum velocity scaling will be obtained by sending a program

change nr.122 command.

- Lights: mapped on notes 119-127

- 127 = yellow/amber light under Vorsetzer mechanism (LED strip).

Light intensity mapped on the velocity byte.

- 126-122 = orange/yellow LED spots

frontal on the Vorsetzer mechanism

- 121 = bright red light on tremulant mechanism

- 120 = white LED spot underside. Note that

this light, by design, always switches between dim and full on.

It cannot be fully off. [2021: now replaced with a red light!]

- 119 = frontal blue light, floor oriented

|

| note: features printed in white

are still to be implemented on the date of this writing. |

Repertoire (all

repertoire playable on <Harma> can also be played on <HarmO>:

| Johann Sebastian Bach: |

Goldberg Variationen (available on CD in a limited edition LPD-001 ('minus

1')

a specific version for <HarmO> is available as well.

|

|

| |

Das Wohltemperierte Klavier |

|

| Ludwig Van Beethoven |

Waldsteinsonate |

|

| Tango's |

La Cumparsita Tango |

|

| |

El choclo Tango |

|

| |

Jealousy Tango |

|

| |

Uno |

|

| Godfried-Willem Raes |

<Harm> for Harma |

2001 |

| |

<Hidden (c) Harms>

MP3

encoded recording of this piece (on Harma) MP3

encoded recording of this piece (on Harma)

|

2001

2010

|

| |

<Vibes> for Vibi, Piperola and Harma |

2001 |

| |

<Trio Paradiso>, for Vibi, Harma and Klung |

2001 |

| |

<Paradiso>, for automat orchestra and backing vocals |

2001 |

| |

<Tekne>, for automat orchestra and devils dance |

2002 |

| |

<Eary Lis Trimbl>, for automat orchestra and musicians |

2002 |

| |

<Flexes>, for automat orchestra and musicians |

2003 |

| |

<Wandern>, for radar controlled automat orchestra and a nude dancer |

2003 |

| |

<Pic Harm>, for picradar controlled Harma and a nude dancer |

2005 |

| |

<Gestrobo Study #HarmO>, for invisible instrument HarmO and a nude

dancer |

2010 |

| Kristof Lauwers |

<Sonata>, for automat orchestra |

2002 |

| Sebastian Bradt |

<Dedication Harma> |

2004 |

| |

<Early Messages> |

2004 |

Service manual & detailed circuit

and maintenance documentation

Following information and documentation is not intended for the general public.

Radial compressor: August Laukhuff, Ventola type 612380. Motor 130 Watt, aussenlaufer.

Star connected for 3-phase operation with Siemens motorcontroller. Windpressure

800 Pa, 3000 l/min when operated on 50 Hz. Rotation speed at 50Hz: 2800 rmp.

Machine number: 6082-8129. Price: 1.309,12 Euro (11/2009)

Tubular solenoids (73): Black Knight 121-420-620-620 (100% duty cycle voltage

12V, diameter 20mm, push type). Resistance: 20ω

Register solenoids (8): Aug.Laukhuff Trakturmagnet, 300810, 24V (10 Newton,

10mm traject) Price: 39,86 Euro (11/2009)

Subbass register solenoids (2): Aug.Laukhuff Ventilmagnet, 24V

Linear stepper motors (2): Nanotec L5609X2008- M6x0.5 (Farnell order nr.: 474-3234).

Shaft: ZSM6-0.5-200 spindle, M6x0.5 (Farnell order nr.: 837-5682). Corresponding

motor controllers: Nanotec SMC42-2,0-1 (Farnell order nr.: 474-3131). Wiring

details:

Windvalve inlet motor: Burroughs Sonceboz type nr. 1251 0228, rated 0.6A/phase

and 0.5 Ohms/phase. Bipolar stepper motor. Dented belt: 78mm length, Gates powergrip.

Connected to the 24V power, the motor draws 1.2A when running with a 186Hz clock.

At 240Hz, it draws 840 mA. This seems to be the optimum clock frequency for

this motor.

Doppler tremulant motor: Canon, 6V type R17CN-EQCB, diameter 41mm, fully screened,

made in Taiwan.

Circuit boards overview:

Power supply:

2 Siemens Sitop Smart 24 V/10 A, nr.6EP1334-2AA01 (Output voltage adjustable

from 22.8 to 28 V) Farnell order nr.: 121-6632

1 Mascot 8921 12 V PSU, desktop 290 W, 20A ( http://www.mascot.no ) Farnell

order nr.: 118-3937

1 5 V/ 1 A, encapsulated module.VxI 14438/000 (http://www.vxipower.com). Farnell

order nr.: 118-6397

3 analog panel meters are provided for power supply monitoring. Therefore Kyuritsu

KM-48 voltmeters, rated 10 V DC, are used. For monitoring the 12 V, a 1% series

resistor of 5 k was used such that a reading of 8 V on the original scale now

corresponds to 12 V. For the two 24 V supplies, the 1% series resistor becomes

20 k. The meters Ri being 10 k and sensitivity 1 mA.

6 boards for the note pallets:

All note solenoids have a common positive voltage connection. The second wires

come together in Weidmueller 6-pole connectors (one for each set) to the note/velo

boards. To get access to the reeds and the springs, first disconnect all these

connectors. Next, remove the U-shaped stainless steel protectors. Then loosen

the bolts joining upper and lower part of the instrument. The solenoid assembly,

the vorsetzer, can be lifted up vertically from the soundboard containing the

reeds. Always keep components in a horizontal position! When the vorsetzer is

taken out, always take care to place it on two stand off blocks such that the

mechanism never comes to rest on the solenoid pushers.

The positive voltage can be adjusted on the power supply (Mascot) printed circuit

board with the multiturn trimmer. The voltage should be adjusted such that when

no velocity pulses are applied, the solenoids develop just enough force to hold

the keys down. Initially we found 8V to be a suitable minimum setting. The maximum

allowable voltage here is +12V. The negative voltage (the first Sitop power

supply) should be adjusted between 20V and 28Volts. Initially we had it set

to 24V. Changing this voltage will change the velocity scaling of the instrument.

The second Sitop power supply is adjusted to 24V positive and feeds the stepping

motors.

The circuitry on the midi input board and the PIC with the motor control worked

out like this:

Wiring tables for the six PIC 18F4620 controller boards:

Board 1:

| board output |

connector pin |

mapping |

remarks |

PIC pin |

| 1 |

2 |

reg, ctrl 70 - 2' |

gnd- -24V |

3 |

| 2 |

3 |

reg, crtl 71 - 8' |

gnd- -24V |

5 |

| 3 |

4 |

reg, ctrl 72 - 16' |

gnd- -24V |

7 |

| 4 |

5 |

reg, ctrl 73 - 4' |

gnd- -24V |

9 |

| 5 |

7 |

reg, ctrl 74, 32' subbass

|

gnd- -24V |

37 |

| 6 |

8 |

light, note 127, Yellow LED strip under pushers

|

keys bottom 12V |

36 |

| 7 |

9 |

note 29 |

pulse/hold |

34, 33 |

| 8 |

10 |

note 30 |

pulse/hold |

30, 29 |

| 9 |

12 |

note 31 |

pulse/hold |

28, 27 |

| 10 |

13 |

note 32 |

pulse/hold |

24, 23 |

| 11 |

14 |

note 33 |

pulse/hold |

22, 21 |

| 12 |

15 |

note 34 |

pulse/hold |

15, 16 |

| 13 |

17 |

note 35 |

pulse/hold |

17, 18 |

| 14 |

18 |

note 36 |

pulse/hold |

19, 20 |

Board 2:

| board output |

connector pin |

mapping |

remarks |

PIC pins |

| 1 |

2 |

note 37 |

hold/velo |

4, 3 |

| 2 |

3 |

note 38 |

|

2, 5 |

| 3 |

4 |

note 39 |

|

6, 7 |

| 4 |

5 |

note 40 |

|

8, 9 |

| 5 |

7 |

note 41 |

|

10, 37 |

| 6 |

8 |

note 42 |

|

36, 35 |

| 7 |

9 |

note 43 |

|

34, 33 |

| 8 |

10 |

note 44 |

|

30, 29 |

| 9 |

12 |

note 45 |

|

28, 27 |

| 10 |

13 |

note 46 |

|

24, 23 |

| 11 |

14 |

note 47 |

|

22, 21 |

| 12 |

15 |

note 48 |

|

15, 16 |

| 13 |

17 |

note 49 |

|

17, 18 |

| 14 |

18 |

note 50 |

|

19, 20 |

Board 3:

| board output |

connector pin |

mapping |

remarks |

| 1 |

2 |

note 51 |

|

| 2 |

3 |

note 52 |

|

| 3 |

4 |

note 53 |

|

| 4 |

5 |

note 54 |

|

| 5 |

7 |

note 55 |

|

| 6 |

8 |

note 56 |

|

| 7 |

9 |

note 57 |

|

| 8 |

10 |

note 58 |

|

| 9 |

12 |

note 59 |

|

| 10 |

13 |

note 60 |

|

| 11 |

14 |

note 61 |

|

| 12 |

15 |

note 62 |

|

| 13 |

17 |

note 63 |

|

| 14 |

18 |

note 64 |

|

Board 4:

| board output |

connector pin |

mapping |

remarks |

| 1 |

2 |

note 65 |

|

| 2 |

3 |

note 66 |

|

| 3 |

4 |

note 67 |

|

| 4 |

5 |

note 68 |

|

| 5 |

7 |

note 69 |

|

| 6 |

8 |

note 70 |

|

| 7 |

9 |

note 71 |

|

| 8 |

10 |

note 72 |

|

| 9 |

12 |

note 73 |

|

| 10 |

13 |

note 74 |

|

| 11 |

14 |

note 75 |

|

| 12 |

15 |

note 76 |

|

| 13 |

17 |

note 77 |

|

| 14 |

18 |

note 78 |

|

Board 5:

| board output |

connector pin |

mapping |

remarks |

| 1 |

2 |

note 79 |

|

| 2 |

3 |

note 80 |

|

| 3 |

4 |

note 81 |

|

| 4 |

5 |

note 82 |

|

| 5 |

7 |

note 83 |

|

| 6 |

8 |

note 84 |

|

| 7 |

9 |

note 85 |

|

| 8 |

10 |

note 86 |

|

| 9 |

12 |

note 87 |

|

| 10 |

13 |

note 88 |

|

| 11 |

14 |

note 89 |

|

| 12 |

15 |

note 90 |

|

| 13 |

17 |

note 91 |

|

| 14 |

18 |

note 92 |

|

Board 6:

| board output |

connector pin |

mapping |

remarks |

pic pin |

| 1 |

2 |

note 93 |

hold/pulse |

4, 3 |

| 2 |

3 |

note 94 |

|

2, 5 |

| 3 |

4 |

note 95 |

|

6, 7 |

| 4 |

5 |

note 96 |

|

8, 9 |

| 5 |

7 |

note 97 |

|

10, 37 |

| 6 |

8 |

note 98 |

|

36, 35 |

| 7 |

9 |

note 99 |

|

34, 33 |

| 8 |

10 |

note 100 |

|

30, 29 |

| 9 |

12 |

note 101 |

hold/ pulse |

28, 27 |

| 10 |

13 |

light

note 121

|

bright red (LED assembly, oriented to tremulant)

|

24 |

| 11 |

14 |

reg, 8' forte |

gnd- -24V |

21 |

| 12 |

15 |

reg, 16' |

gnd- -24V |

16 |

| 13 |

17 |

reg, 8' clarinet |

gnr- -24V |

18 |

| 14 |

18 |

reg. 4' oboe |

gnd- -24V |

20 |

Detail of the three different ways these boards are populated, depending on

the functionality:

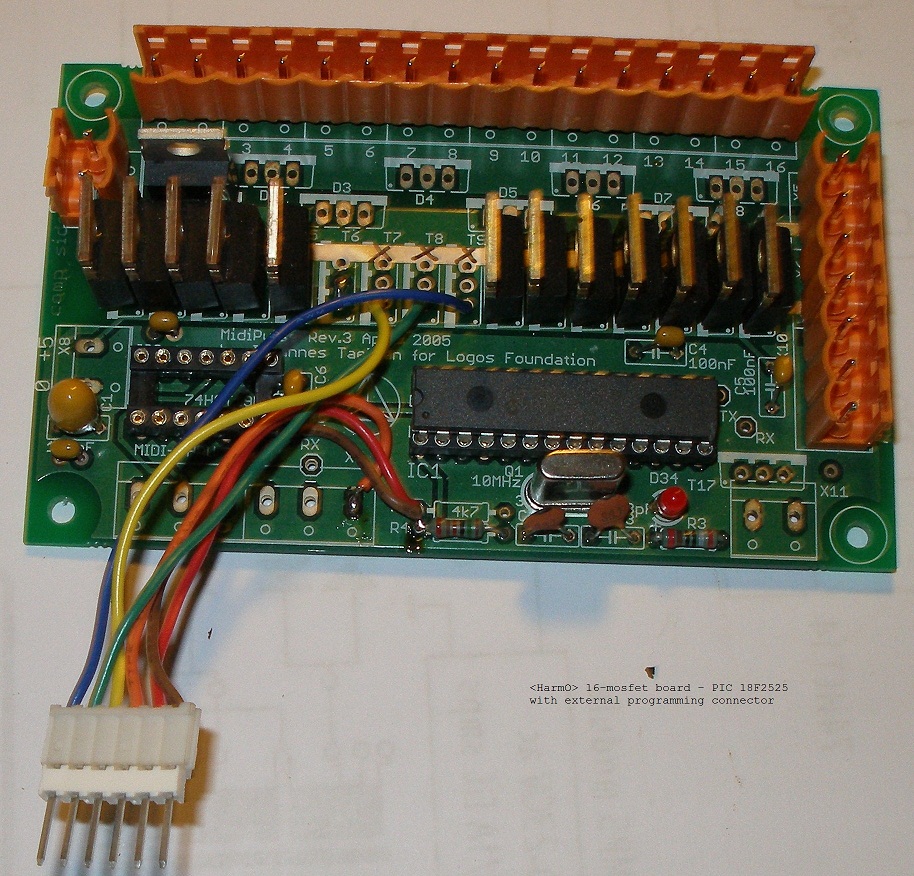

Board 7 - Midi-hub board: (PIC 18F2525), board version 2006.This board originally

controled the radial compressor motor, now it does the swell motors and the

tremulant DC-motor. The board is mount under the windchest on a piece of polycarbonate.

| board output |

connector pin |

mapping |

remarks |

wire color |

pic pin |

| |

X17-1 |

- |

GND |

|

- |

| 1 |

X17-2 |

ctrl 7 |

motor speed (0-10V) |

|

13 |

| 2 |

X17-3 |

ctrl 82 |

tremulant (0-10V) this mosfet has a small cooling

fin. |

DC motor Canon (6V) |

12 |

| |

X17-4 |

- |

+10 V from motor ctrl. |

|

- |

| |

X11-1 |

|

GND |

|

- |

| 3 |

X11-2 |

ctrl 66 |

wind motor ON/OFF |

|

5 |

| 4 |

X11-3 |

|

spare (optional sensor input front swell) |

|

4 |

| |

X11-4 |

|

+ 24 V from motor ctrl. |

|

- |

| |

X12-1 |

|

GND |

black/white |

- |

| 5 |

X12-2 |

|

frontal swell enable |

gray |

3 |

| 6 |

X12-3 |

|

frontal swell clock |

green |

2 |

| |

X12-4 |

- |

nc |

|

- |

| |

X15-1 |

- |

GND |

green/yellow |

- |

| 7 |

X15-2 |

|

frontal swell direction |

purple |

25 |

| |

X15-3 |

|

back swell enable |

brown |

24 |

| 8 |

X15-4 |

|

nc |

|

- |

| |

X16-1 |

GND |

|

|

- |

| 2 |

X16-2 |

=X17-3 |

tremulant (0-10V pwm) |

yellow

|

12 |

| |

X16-3 |

+ power |

tremulant positive supply +12V |

pink |

- |

| 9 |

X16-4 |

|

back swell clock |

orange |

16 |

| 10 |

X16-5 |

|

back swell direction |

yellow |

15 |

| |

X16-6 |

input |

sensor input back swell |

white |

7 |

Board 8 - Pulse board (PIC 18F2525) [board version rev.3, april 2005, modif..21.12.2009]

This board controls the ghost beaters, the windslide (ctrl.1), the ghost beaters

and the lites. This board is located on the same polycarbonate plate as the

midi-hub board and is located in the back of the mains power entry. The board

did in its original design not have a programming connector, but in this version

we constructed a 'flying' 6-pin connector such that in circuit debugging and

programming becomes possible as for all other processor boards in <harmO>.

| board output |

connector pin |

mapping |

remarks |

wire color |

pic pin |

| 1 |

X1-1 |

note 0 |

pulse beater 24V |

grey |

4 |

| 2 |

X1-2 |

note 1 |

pulse beater 24V |

purple |

3 |

| 3 |

X1-3 |

enable windslide motor

(green)

|

no BYV32 diode !

mosfet

|

green |

2 |

| 4 |

X1-4 |

windslide motor clock

(brown)

|

no BYV32 diode !

mosfet

|

brown |

5 |

| 5 |

X2-1 |

windslide motor dir

(blue)

|

no BYV32 diode !

mosfet

|

blue |

6 |

| 6 |

X2-2 |

analog input (R-sensor)

AN4 in PIC specs

|

no BYV32 diode

no mosfet!

|

nc |

7 |

| 7 |

X2-3 |

ICP - external connector |

avoid use |

yellow |

28 |

| 8 |

X2-4 |

ICP - external connector |

avoid use |

green |

27 |

| 9 |

X3-1 |

ICP - external connector |

avoid use |

blue |

26 |

| 10 |

X3-2 |

lite yellow. note 126 |

12V led spot |

brown |

25 |

| 11 |

X3-3 |

lite yellow. 125 |

12V led spot |

orange |

24 |

| 12 |

X3-4 |

lite yellow , 124 |

12V led spot |

yellow |

23 |

| 13 |

X4-1 |

lite yellow, 123 |

12V led spot |

green |

22 |

| 14 |

X4-2 |

lite yellow, 122 |

12V led spot |

blue |

21 |

| 15 |

X4-3 |

lite blue , 119 front lite above mirror |

12V led large spot |

blue |

16 |

| 16 |

X4-4 |

ac solid state relay

lite 120, white

|

white LED spot (230V) |

yellow |

15 |

| pwm |

X11 |

controller 81 |

analog pwm out

|

|

13 |

The 'flying' connector for in circuit debugging and programming is shown in

the picture below:

Power supplies:

- +12V dc (positive hold voltage): 20A, 260 Watt - SMPS power supply (Mascot)

- - 24V dc (negative pulse voltage): 10A Sitop (Siemens)

- +24V dc (register solenoids, stepper motors): 10A Sitop (Siemens)

- +5V dc logic power, 2A (Encapsulated module)

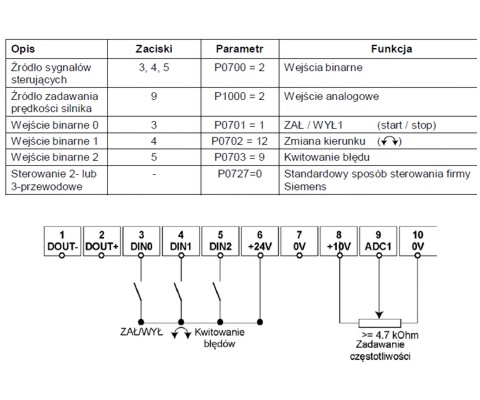

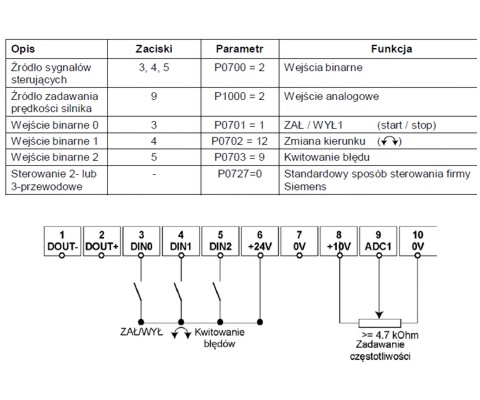

Programming information and settings for the Siemens Sinamics G110 motor

controller:

| Parameter nr. |

setting |

comment |

| P0003 - User Access level |

3 |

- 1= standard

- 2 = extended

- 3 = expert

|

| P0004 - access control filter params |

0 |

allow access to all parameters of P0003 = 3 |

| P0005 - display parameter |

21 |

display motor frequency |

| P0010 - commisioning params |

0 |

must be set to 1 to change motor params.

For access to P4 params and normal operation, must be set to 0

|

| P0100 - Europe/ US |

0 |

= default value (Europe, 50Hz) |

| P0210 - voltage |

230V |

mains voltage |

| P0304 - nominal motor voltage |

230V |

motor specs. (star connected) |

| P0305 - motor current |

0.56A |

motor specs. |

| P0307 - motor power |

0.130 kW |

motor specs.motor specs. (name plate says 75W, but current

is 0.55A at 230V) |

| P0310 - nominal motor frequency |

80Hz |

50 Hz after motor specs., but otherwise we cannot speed up... |

| P0311 - nominal motor rpm |

2800 |

motor specs. |

| P0700 - ctrl. via control panel or digital I/O |

2 |

use digital inputs for ctrl. |

| P1000 - select frequency setpoint |

2 |

set analog setpoint (1= operator panel f-ctrl) |

| P1080 - min.. motor frequency |

10 Hz |

|

| P1082 - max. motor frequency |

80Hz |

the practical maximum freq. will be ca. 60Hz |

| P1120 - ramp up-time |

2" |

|

| P1121 - ramp down time |

4" |

|

| P3900 - end quick commisioning |

1 |

resets P0010 |

With these settings we obtain the following midi correspondence:

| midi value for ctrl.7 |

motor frequency |

musical result |

| 1 |

10 Hz |

pppp |

| 5 |

|

|

| 10 |

|

|

| 20 |

|

|

| 30 |

28 Hz |

p |

| 40 |

35.5Hz |

mp |

| 50 |

40 Hz |

mf |

| 60 |

44 Hz |

mf |

| 70 |

|

|

| 80 |

50 Hz |

f |

| 90 |

|

|

| 100 |

56 Hz |

ff |

| 127 |

60 Hz |

fff |

Note that when no notes are being played, wind pressure should always be reduced

to the smallest practical value. Also, required wind pressure is a function

of the number of notes playing as well as of their pitch, since lower reeds

require a lot more wind than the high ones. With wind pressures higher than

midi value 60, leaks can occur when no notes are played. Since 2015 all these

problems have been adressed with a new intelligent motor controller. The remarks

are still valid, but are now solved in the firmware.

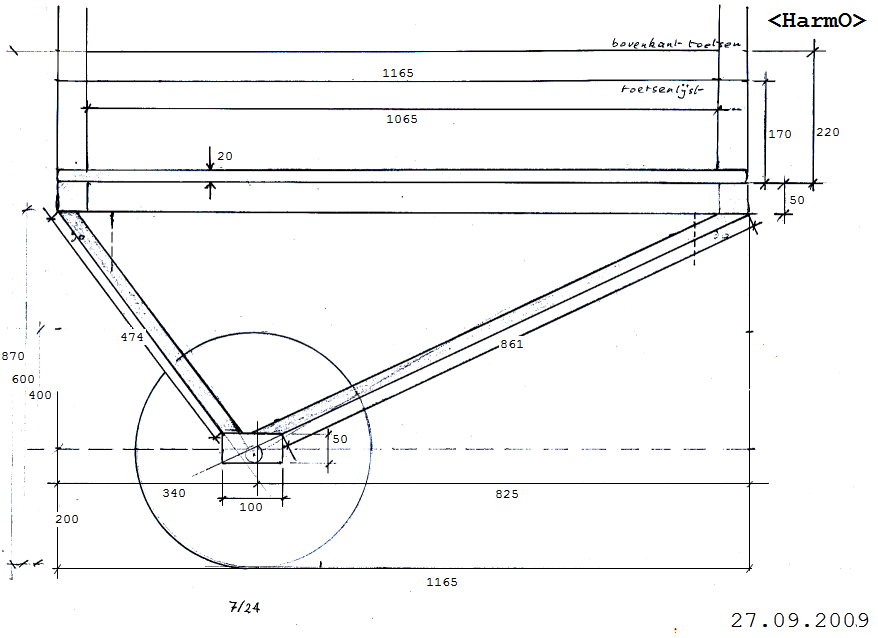

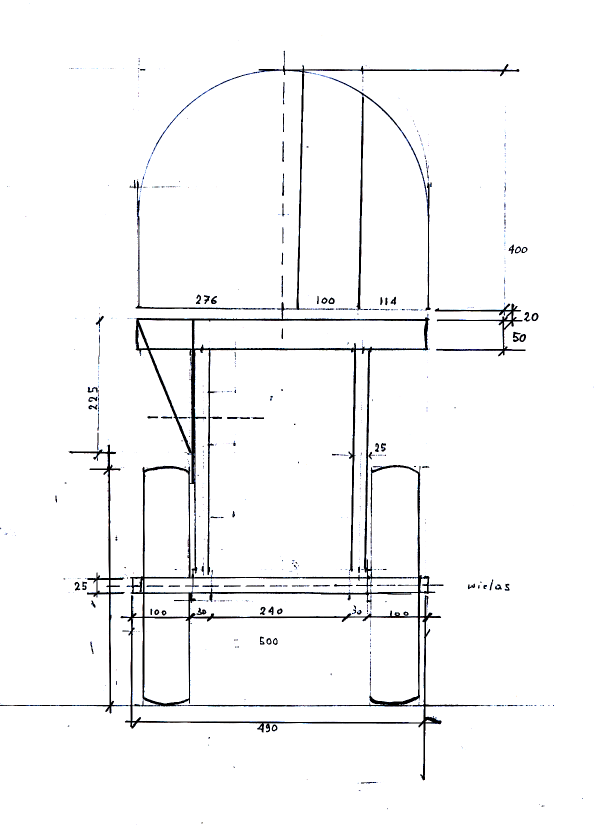

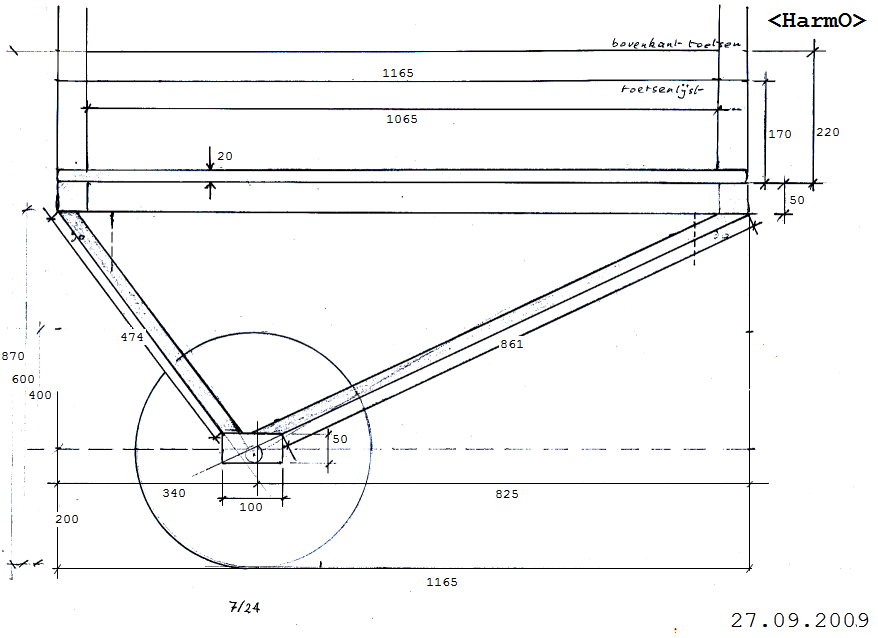

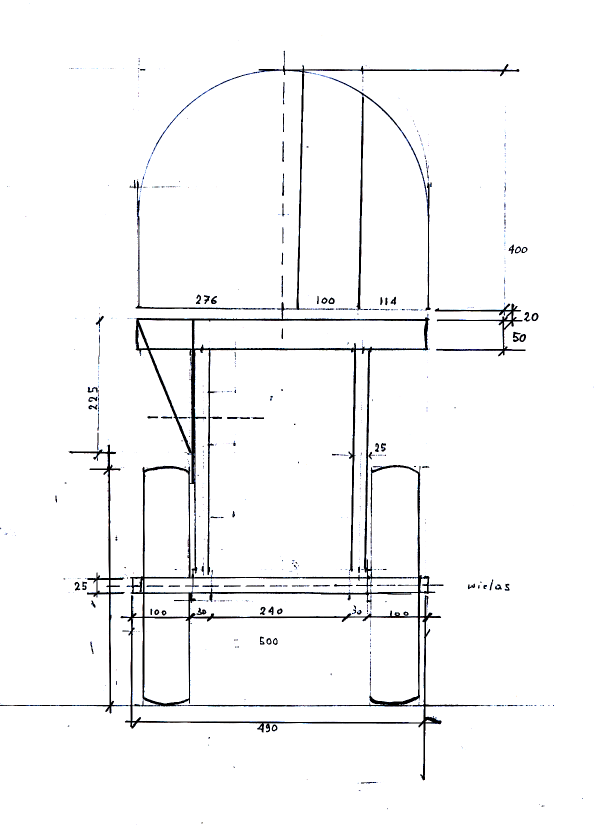

Metal parts sizing and drawings:

View from the bass side:

Lights:

- Five frontal yellow lights: 1W high power LED reflectors. Lifetime: 50000h.

GU5.3 socket, view angle 25 degrees, diameter 50mm. Voltage 12V. Forward current

350 mA. Operating temperature:-40C to +80C. Type: HomeStar 574568. Source:

Conrad.

- White LED spotlight on the bottom: QRB111. Voltage 230V ac. Switched with

a solid state relay. Lamp base: GU10. As a replacement, Verbatim #52045, 1206-162

can also be used.

- Yellow LED strips (flexible self adhesive strips with SMD LED's) rated for

12V dc.

- Bright red LED light oriented towards tremulant: LRW5SN VPA1A, 120 degrees,

Vf=3.3V. Two such LED's in series with current limiting wirewound power resistor.

(mapped on midi note 121)

Technical revisions and maintenance notes:

- 18.09.2009: Instrument signaled to us by Zimcke Van de Staey.

- 19.09.2009: purchase of the original Emile Kerkhoff instrument in Herselt.

Brought to Ghent by Yvan Vander Sanden. Basic tuning checked to be 440 Hz.

The case had to be taken apart in order to make the transport possible.

- 22-24.09.2009: Measurement of components, further dismantling of the original

instrument, first sketches for a new design.

- 26.09.2009: original instrument further taken apart and analyzed.

On the picture the instrument is shown in the state we received it in the

workshop.

On the picture the instrument is shown in the state we received it in the

workshop. The sound board has a series number: 54938. After removal of the keyboard

assembly the box containing the 13 reeds for the subbass extension becomes

visible. The problem will be to make all the mechanics such that noise is

minimized. We decided to preserve the keyboard, since it seems to help reducing

the required solenoid forces for they function as levers. Solenoids ordered

from Farnell: Black Knight type 121-420-620-620.

The sound board has a series number: 54938. After removal of the keyboard

assembly the box containing the 13 reeds for the subbass extension becomes

visible. The problem will be to make all the mechanics such that noise is

minimized. We decided to preserve the keyboard, since it seems to help reducing

the required solenoid forces for they function as levers. Solenoids ordered

from Farnell: Black Knight type 121-420-620-620.

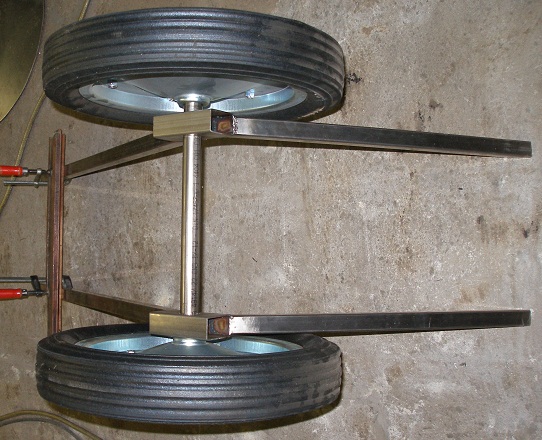

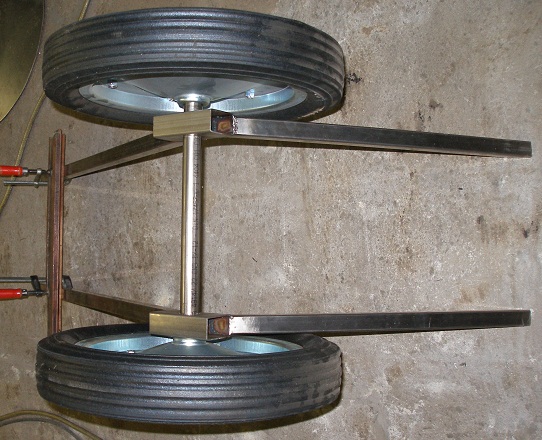

- 27.09.2009: TIG welding of the support frame for the bottom plate of the

windchest: 2 pieces 50x50x2 square tube, length 484mm welded on 50x3x1165mm,

flat stainless steel. Wheel axis tubing: 25 x 2 x 500. Wheels: 400mm diameter.

Ventola blower ordered from August Laukhuff. (order number 612380). This blower

will be mounted vertically, under the windchest. The bottom plate of the windchest

is to be mounted on this frame in a permanent way.

- 28.09.2009: Harmo building project shown and explained to Kristof Lauwers

and Troy Rogers. Further design of the wheelbase.

- 29.09.2009: TIG welding work on the frontal square tubing connecting the

wheel assembly to the windchest carrier.

- 30.09.2009: Further TIG welding work on the trolley. Some tuition given

to Troy Rogers on welding technology, metal working and robot construction.

- 01.10.2009: drawing of circuit overview. Estimation of board real estate

required.

- 02.10.2009: design session for the mechanics of the registers and expression

mechanism.

- 03.10.2009: Further work on the trolley construction.

- 04.10.2009: design of wind-inlet and motor mounting. Varnish restored with

polyvinyl alcohol.

- 05.10.2009: Drawing of the welding plan.

- 06.10.2009: Start construction of the solenoid holding structure. The structure

is a piece of stainless steel plate, 2mm thick bend in an asymmetric U shape:

140mm x 60mm x 50mm, cut to a length of 1050mm. Drawing, marking, centering

and drilling of the 73 holes, diameter 14.5mm, with the help of Troy Rogers.

Delivery of a first set of 29 solenoids from Farnell.

- 09.10.2009: Drilling and centering works.

- 11-12.10.2009: More drilling work... all 14.5mm holes drilled.

- 13.10.2009: 10mm thick side-plates for the 'vorsetzer' cut out. Placement

of the six note-control PC-boards decided: the will lean against the back

of the solenoid assembly. The wires from the solenoids will get through the

PC boards via large holes drilled in the backplate. This gives us space for

some lights on the frontal side.

- 14.10.2009: Further work on the vorsetzer design.

- 15.10.2009: T-shaped back bounce bar designed. This can be either made of

hardened brass or stainless steel 30x30. The flat side should have 6 to 10mm

thick felt. Measurement of required force to pull the registers: 5 Newton

(peak <=10 Newton) Thus August Laukhuff - Trakturmagnet, 24 V 0.5 A @ 100%DC

- 10 Newton

can be used for all 8 registers. The power supply at 24V therefore will have

to be dimensioned for at least 4A at 24V continuous. A 100 Watt SMPS type

can be used. The front and back swell require a force smaller than 3 Newton,

when the needle return springs are removed. With the springs, the required

force is 10 to 15 Newton. We will try softshift solenoids: Ledex Softshift

type 5EP, number 193015-026. Cold DC resistance 10.3 Ohm. Nominal working

voltage at 100% duty cycle: 14 V (force = 8 Newton), at 50% (force = 18 Newton)

, 20 V, at 25% (force= 30Newton) , 28 V at 10%, 44 V (force= 50 Newton) .

Price (no joke): 144 US $ a piece... Since we expect most users to have the

swells opened most of the time, we should design for operation at 100% duty

cycle.

can be used for all 8 registers. The power supply at 24V therefore will have

to be dimensioned for at least 4A at 24V continuous. A 100 Watt SMPS type

can be used. The front and back swell require a force smaller than 3 Newton,

when the needle return springs are removed. With the springs, the required

force is 10 to 15 Newton. We will try softshift solenoids: Ledex Softshift

type 5EP, number 193015-026. Cold DC resistance 10.3 Ohm. Nominal working

voltage at 100% duty cycle: 14 V (force = 8 Newton), at 50% (force = 18 Newton)

, 20 V, at 25% (force= 30Newton) , 28 V at 10%, 44 V (force= 50 Newton) .

Price (no joke): 144 US $ a piece... Since we expect most users to have the

swells opened most of the time, we should design for operation at 100% duty

cycle.

- 17.10.2009: Construction of the power supply bars in red copper. Drilling

of the 12 mm holes in the mounting flanges. Vorsetzer assembly welded together.

- 18.10.2009: Test assembly.

Exact measurement of required solenoid travel on the different components

to be automated. The hold voltage for the key-solenoids will definitely not

have to be greater than 12V. If we would want to allow full clusters, this

would entail a power supply capable of delivering some 45 A. (500 Watt).The

velocity pulse voltage can be a relaxed 24 V and certainly not more than 48

V.

Exact measurement of required solenoid travel on the different components

to be automated. The hold voltage for the key-solenoids will definitely not

have to be greater than 12V. If we would want to allow full clusters, this

would entail a power supply capable of delivering some 45 A. (500 Watt).The

velocity pulse voltage can be a relaxed 24 V and certainly not more than 48

V.

- 19.10.2009: In place check & verify design:

Sideplates to

carry the vorzetzer.

Sideplates to

carry the vorzetzer.

Left en right side

pushing solenoids with rubber feet.

Left en right side

pushing solenoids with rubber feet.

- 20.10.2009: Wiring tables fixed for the pulse/hold boards. Bending of the

limiting side arc profiles (50 x 3 stainless steel) with Troy Rogers.

- 22.10.2009: News from Laukhuff: the compressor, as ordered, will be delivered

week 44, that is first week of November.

- 23.10.2009: Cutting and drilling of the four vertically mounted register

solenoid holding plates.

- 24.10.2009: further work on the carrying structure for the vorsetzer and

the register solenoids. The two solenoids on each side placed in a horizontal

plane are mounted with M3 bolts. The holes in the chassis are threaded. The

vertical ones are mounted with bolt and nut, M3. Mounting slots drilled and

filed out.

\

\

- 25.10.2009: Mounting slots bass side filed out. Solenoids ordered from Laukhuff:

Trakturmagnet 24V, catalog number 300810. TIG welding work on the bass side

vorsetzer holder.

- 26.10.2009: Welding work on the arc, treble side after cutting out the arc

section in the thick vertical holding plate. Construction of a guiding wheel

with a 16mm outer diameter ball bearing for the movement of the frontal shutters.

- 27.10.2009: Bass side finished similarly as the treble side: arc cut out

and welded on the thick vertical plate. Removal of all needle springs on the

registers and the shutters. Experiments with the soft shift solenoids (Size

5EP, Lucas Ledex, order number 193015-026) carried out. At 100% duty cycle

operated on 14V dc these have a starting force of 8.8 Newton, at the end of

the 10mm stroke traject the force goes up a bit, reaching 13.3 Newton. Power

consumption under these conditions is about 21 Watt. Speed (unloaded) is ca.

45ms for the full traject. Wheel mounted on the key-holder plate. Pulling

thread connected to the frontal shutter.

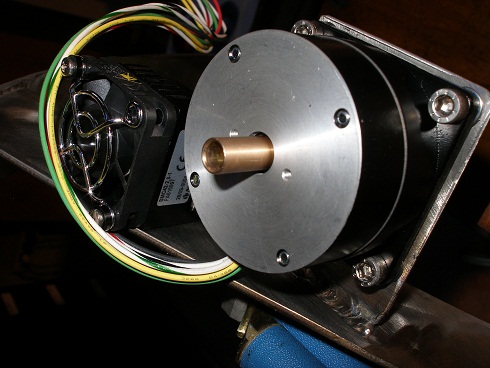

- 28.10.2009: Linear stepper motors ordered as an alternative for the soft

shift solenoids: Nanotec L5609X2008-M6x0.5. This type has a thrust of 85 Newton,

a resolution of 0.00125 mm and a feed of 20 mm/s. Current per winding is 2

A. ( http://www.nanotec.com ). The cost (including the spindle, with a M6

x 0.5 thread, which is to be ordered separately) is about 120 Euro a piece.

We ordered stepper controllers for these motors (Type SMC42) and these cost

93 Euro a piece, bringing the price for the entire mechanism to about 426

Euro. Mounting plates with holes for either softshifts or these linear motors

made and welded into the treble side chassis.

- 29.10.2009: Design of the mechanism for the back shutters to be mounted

on the bass side chassis. Here the traject can be kept pure vertical without

any need for a guiding wheel. The way it looks now, we can probably go without

using sensors, on the sole condition that on startup, the shutter valves will

always be in a fully closed position. They can be brought there by hand, by

rotating the cylindrical part of the hollow bronze motor shaft. The midi controller

range 0-127 should be remapped on the number of rotations required for the

full traject. A counter should be kept in the software. Welding and mounting

works on the bass side chassis for the linear stepping motor.

The pictures

show the welded and roughly brushed assembly for the bass side chassis with

no parts mounted.

The pictures

show the welded and roughly brushed assembly for the bass side chassis with

no parts mounted.

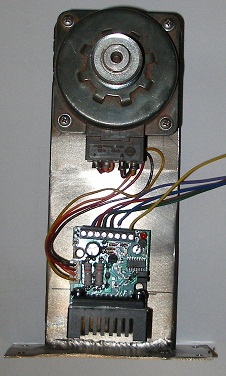

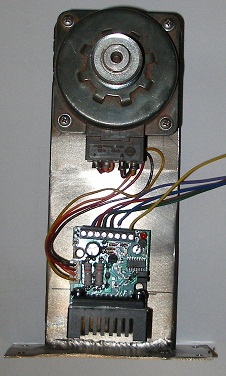

- 30.10.2009: Nanotec stepper motor controller delivered.

The fan will have to be removed since it is noisy and in this application

not even required, taking into account the duty cycle applicable to the shutter

valves. The controllers will be mounted right on the curved side chassis in

order to reduce possible EMC from the otherwise long wire bundles to the motors.

The motors have 8 wires and the windings are connected in series for full

bipolar operation. Mounting holes drilled in the side chassis. The controllers

are mounted with two M3 x 10 bolts.

The fan will have to be removed since it is noisy and in this application

not even required, taking into account the duty cycle applicable to the shutter

valves. The controllers will be mounted right on the curved side chassis in

order to reduce possible EMC from the otherwise long wire bundles to the motors.

The motors have 8 wires and the windings are connected in series for full

bipolar operation. Mounting holes drilled in the side chassis. The controllers

are mounted with two M3 x 10 bolts.

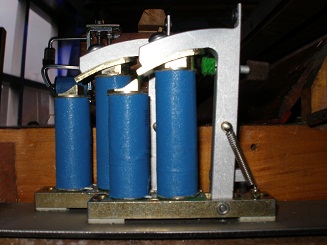

- 31.10.2009: Construction of the register lifter for the subbass box.

The picture shows the construction, but the felt washers are missing. The

solenoid is a small Laukhuff pallet lifter rated for 24V. The force at the

nominal voltage is too small to securely lift up the register valve, but when

driven with 30V it opens smoothly. The hold voltage can be kept at 24V. Another

solution would be to add a second solenoid -operating in parallel- at the

other side of the valve, thus doubling the force. That's the way we decided

to go, for it saved us complications with too many different power supply

voltages. Experiments did reveal that it would be possible to use the registers

in a gradual way, provided they are always switched off with the full voltage

and then lowering this voltage with PWM. The down traject is very well controllable,

not the upwards traject.

The picture shows the construction, but the felt washers are missing. The

solenoid is a small Laukhuff pallet lifter rated for 24V. The force at the

nominal voltage is too small to securely lift up the register valve, but when

driven with 30V it opens smoothly. The hold voltage can be kept at 24V. Another

solution would be to add a second solenoid -operating in parallel- at the

other side of the valve, thus doubling the force. That's the way we decided

to go, for it saved us complications with too many different power supply

voltages. Experiments did reveal that it would be possible to use the registers

in a gradual way, provided they are always switched off with the full voltage

and then lowering this voltage with PWM. The down traject is very well controllable,

not the upwards traject.

- 01.11.2009:

Construction

of the tremulant mechanism using a softshift solenoid and a conical valve.

The seating for the valve was milled out in hard wood, such that it can be

glued right on the 16mm hole for the original tremulant, in the soundboard.

Start mounting of the key pressing solenoids on the Vorsetzer chassis. The

nuts are fixed with Loctite 243 (blue).

Construction

of the tremulant mechanism using a softshift solenoid and a conical valve.

The seating for the valve was milled out in hard wood, such that it can be

glued right on the 16mm hole for the original tremulant, in the soundboard.

Start mounting of the key pressing solenoids on the Vorsetzer chassis. The

nuts are fixed with Loctite 243 (blue).

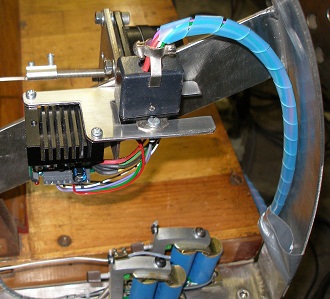

- 02.11.2009: Assembly of the spindle motors and controllers:

The fans have

to be removed. The first picture shows the horizontal spindle motor driving

the frontal swell, the second the vertical spindle motor driving the backside

swell. Start soldering work on the note driver boards. The bass side board

is only fully populated for the highest 8 outputs. Series diodes here are

BYV28 - 200V. Mosfets: all IRL640, P-channel mosfets: BSP254A. It is harmless

to mount all P-channel mosfets, regardless the way the board is used. Troy

Rogers is helping us out with the soldering works on these boards. Boards

2-5 are identical, boards 1 and 6 have a slightly different component selection

due to the use of outputs for the register solenoids. Just for the sake of

comparative measurement and evaluation, we populated the high note board (board

6) with BS250 P-channel mosfets and did all soldering lead-free.

The fans have

to be removed. The first picture shows the horizontal spindle motor driving

the frontal swell, the second the vertical spindle motor driving the backside

swell. Start soldering work on the note driver boards. The bass side board

is only fully populated for the highest 8 outputs. Series diodes here are

BYV28 - 200V. Mosfets: all IRL640, P-channel mosfets: BSP254A. It is harmless

to mount all P-channel mosfets, regardless the way the board is used. Troy

Rogers is helping us out with the soldering works on these boards. Boards

2-5 are identical, boards 1 and 6 have a slightly different component selection

due to the use of outputs for the register solenoids. Just for the sake of

comparative measurement and evaluation, we populated the high note board (board

6) with BS250 P-channel mosfets and did all soldering lead-free.

- 03.11.2009: Continuation of soldering works. We run out of diodes... fast

order to Farnell. Three board are already fully populated and finished. Three

more to go... The picture shows board 6, with special component selection

in order that the same board can be used for switching 4 registers, one light

and nine notes.

Since

the register solenoids are switched to the negative 24V supply, the protection

diodes (BYV32) have their central pin connected to ground. In order to gain

some more experience in future technologies (Sn/Pb solder may disappear...)

, we soldered this board leadless. It looks dull...

Since

the register solenoids are switched to the negative 24V supply, the protection

diodes (BYV32) have their central pin connected to ground. In order to gain

some more experience in future technologies (Sn/Pb solder may disappear...)

, we soldered this board leadless. It looks dull...

- 04.11.2009: Work on the red copper power supply bars connecting the boards

on the backside of the vorsetzer. The missing tracker solenoids from Laukhuff

have flown in and thus the register automation can be finished as well. Orders

placed for two Siemens Sitop 24V/10A supplies as well as for a 20A 12V supply,

made in Norway. Lets pray they come without fans and can cope with the surges

caused by the switching solenoids... With these components in the power supply,

polyphony will be limited to 32 notes simultaneous. We decided not to provide

full 73 note polyphony (requiring a 45A power supply for the +12V) because

the compressor would never be capable to provide enough wind to make all those

reeds sound properly.

- 05.11.2009: delivery of the compressor as ordered, only... Laukhuff did

mount the regulation valve on the suction side, whereas we wanted it on the

wind inlet side... This way it does not fit on the trolley we have already

welded together. Finalisation of the board soldering works after delivery

of the missing diodes by Farnell. The power supplies came flowing in and they

are fan-less!

- 06.11.2009: Preliminary mounting and assembly of the entire robot with clamps.

Verification of the construction drawings. Start construction of the windchest

inlet for the compressor.

Opening of

the original windchest and pallet/reed check. We took the decision to leave

the slider wind control on the suction side.

Opening of

the original windchest and pallet/reed check. We took the decision to leave

the slider wind control on the suction side.

- 07.11.2009: Welding works on the trolley. Design of an automation for the

windvalve; a motor driven dented belt seems appropriate here.

The windchest slider can be seen on the picture. The motor, the rotor is clearly

visible, mounted on its supporting bars:

The windchest slider can be seen on the picture. The motor, the rotor is clearly

visible, mounted on its supporting bars:

We may even have enough space for the power supply (12V/20A) under the bottomplate

of the motor. Closing blocks made from teakwood for the closing sides of the

windchest inlet. These are glued on with silicone compound. After curing,

we will close the windchest with a plate of 2mm thick stainless steel, 960mm

x 24mm.

We may even have enough space for the power supply (12V/20A) under the bottomplate

of the motor. Closing blocks made from teakwood for the closing sides of the

windchest inlet. These are glued on with silicone compound. After curing,

we will close the windchest with a plate of 2mm thick stainless steel, 960mm

x 24mm.

- 08.11.2009: Positioning of the power supply components and the Siemens motor

controller. Mounting brackets made for motor controller, two Siemens power

supplies (rail mount) and the 12V power supply. Power wiring can start now.

The 5V power supply still has to be given a place. Windchest closed with 2mm

stainless steel plate. Recycled antique power switch mounted under the windchest.

In this picture we see the 12V power supply mounted under the motor:

This picture shows the two Siemens 24V power supplies:

This picture shows the two Siemens 24V power supplies: This is a view from underneath, showing the now completely closed windchest

inlet:

This is a view from underneath, showing the now completely closed windchest

inlet:  This

picture shows the positioning of the motor controller such that it is easy

accessible for the programming of the motor parameters:

This

picture shows the positioning of the motor controller such that it is easy

accessible for the programming of the motor parameters:

- 09.11.2009: Placement of 5V power supply. Design of the mounting of the

power inlet, the midi hub board and the extra required board for the ghost

and the steppers. Wiring of the all mains connections as well as the power

switch. The motor is now star-connected for operation on 3-phase 230V.

- 10.11.2009: Mounting of the mains power inlet (male CEE blue). Cutting out

of a polycarbonate carrier plate for the midi input board. Check of motor

operation. Should we provide build in metering/monitoring of the critical

voltages? Start of the design and construction of the third standing leg.

- 11.11.2009: Construction of the standing leg. This leg is demountable and

fixed to the chassis with two 12mm bolts. Programming of the motor controller

and test. The motor to windslide connection is still a bit leaky. Fixing bolts

mounted for the windchest closing plate (M4 x 35). White LED spotlight mounted

on the underside, pointing to the floor.

- 12.11.2009: Construction of the steering handle and the wire feedthroughs

to the upper side of the robot. Design of a metering panel. Design of the

poltergeist... Construction of the power feeds in red copper strips mounted

under the windchest. The screw heads (brass screws) are soldered to the copper

strips.

- 13.11.2009: The spindles with the M6x0.5 thread came in. Wiring of the spindle

steppers. Mounting of the ghost solenoids on the back of the windchest. Beaters

are made of wood. Cables bundled on the underside.

- 14.11.2009: Wiring of the midi-input board. We may run out of Weidmueller

connectors today... Mounting of an experimental drive for the windvalve on

the motor. It's using a recycled Burroughs Sonceboz motor (type 1251 0228)

rated 0.6A /phase and 9.5 Ohm/phase and a Nanotec motor controller. Furthermore

it drives a dented belt (cut) length 78cm that connects at both ends to the

slide with two M3 bolts.

Cutting out

of the front panel for the analog meters for power supply monitoring. Welding

of the stand off's.

Cutting out

of the front panel for the analog meters for power supply monitoring. Welding

of the stand off's.

- 15.11.2009: Finish of the analog power supply voltage metering panel. Mounting

of the Nanotec stepping motor controller for the Burroughs stepper. Tests

of this motor in combination with the controller: the optimum clock frequency

for this motor seems to fall in the range 186 Hz to 240 Hz. At 186 Hz it draws

(both phases together) 1.2 A from our 24 V bench supply. At 240 Hz, the current

sinks to 840 mA. Higher clocks reduce the torque such that it becomes unusable

in this application. It it essential to set the enable pin to high whenever

the motor is not running. The holding current at halt is way too high, and

we do not need any holding torque anyway. For the potentiometer sensor, we

need a dented wheel with a diameter of minimum 30 mm, since we should have

less than 300 degrees of rotation for a movement traject of 65 mm. Start writing

out of the PIC programming specifications.

- 16.11.2009: Up to MEA for ordering the missing mechanical parts... Check

of component placement and lay out of midi hub board recycled from the previous

version of Autosax. This board can take care of the compressor motor as well

as the two linear steppers for the swells.

- 17.11.2009: Component selection and placement for the small pulse board.

Since this board does not have programming pins, we make sure not to use those

pins on the pic, such that we preserve the goodies of in circuit debugging.

Wiring windslide motor controller to mini-PIC board. Finishing of the horizontal

movement of the windslide, using an extra dented guiding wheel in nylon. Belt

cut to size and fixed to the slide with M3 bolts and an insulating washer.

- 18.11.2009: M&M darkness concert: no HarmO works. To to: change the

Burroughs motor bolts to M3.5 x40 types. (Now: M3 x 50)

- 19.11.2009: further work on PIC-specs. Further work on wiring as well as

mounting of the pulse/hold boards on the vorsetzer. Copper power supply rails

fitted to the six boards with assistance from Troy Rogers. Saturday promises

to become PIC programming day with Johannes Taelman...

- 20.11.2009: Weidmueller connectors delivered. Further wiring... First test

of the reeds and registers with the new wind supply. In the high treble, there

are quite many problems with the reeds. The design of the tremulant using

a conical valve was a big mistake as it came out. The tremulant in a reed

organ does not work at all in the same way as in pipeorgans, but simply works

by waving a reflective surface in front of the sound source... We are up for

a new design now.

- 21.11.2009: Reed testing. First programming session on the PIC's with Johannes

Taelman. All note/velo boards programmed (boards 1 to 6) . Midi-hub board

PIC programmed for compressor motor functions. To be done: stepper motors

for swells as well as the PIC processor on the 16-output board. Mounting of

the five frontal yellow 1W high power LED reflectors.

- 22.11.2009: Wiring of the 5 frontal lights. Experiments with different doppler-based

tremulant drives. Wiring of the solenoids finished by Troy Rogers. Found a

nice DC motor from an old portable tape recorder very suitable for driving

the doppler-tremulant. The advantage of using a DC motor here being silent

operation and ease of control: it just requires a single PWM output from a

PIC. The motor is rated for 6V, but can be driven at much higher voltages.

As an alternative, a Crouzet stepper could be used with a steering circuit

as:

The

50k pot could be exchanged for an optor and thus the circuit would become

compatible with the PWM PIC output drive.

The

50k pot could be exchanged for an optor and thus the circuit would become

compatible with the PWM PIC output drive.

- 24.11.2009: Design and construction of a connector for the high side spindle

motor (Bulgin 8-way connector), such that the side parts can be taken of without

having to loosen screws. Two connector contacts are as yet uncommisioned.

Final wiring of the high side register solenoids.

- 25.11.2009: Design of a similar connector for the low side. The support

for the 12-pole Bulgin connectors selected here, welded on the structure.

The input signal for an optional sensor is connected in the male connector

(white wire). Wiring of the bass-side. Wire bundling.

- 26.11.2009: further wiring: subbassregisterbox. Corrections of the attack

points of the solenoids on the keys. Fixation of the rubber feet on the anchors

with cyanoacrylate glue (Loctite 431). GMT test code written by Kristof Lauwers

tested on the instrument. HarmO played already its first complete scale...

Some reeds need fixing however. There is a noticeable difference in the required

velocities for the front row solenoids as compared to those on the back row.

This must be fixed in the sysex lookups.

- 27.11.2009: Wiring of the two super bright red led's for the tremulant mechanism.

This will work as a rotating flashlight. Construction of tracker wires for

the register solenoids using guitar strings. This is as yet not an optimum

solution and the registers may need a small spring or counter weight to make

sure they always return to a fully closed position. Construction of the wings

and the motor mount for the tremulant mechanism. The wings are made from Hasberg

measurement steel, 50mm wide and 0.5mm thick.

- 28.11.2009: Search for a solution for the 2-pole connector required for

demounting the subbasbox register solenoid assembly. Rewiring of the ground

connections for the high side register solenoids. Rotator for the tremulant

mounting with a PTFE spacer. Fixed on 2 mm motor shaft with cyanoacrylate.

The motor mount was made from black tropical hardwood, glued to the stainless

steel baseplate with silicon glue.

- 29.11.2009: Wiring and mounting of the tremulant mechanism. Test controller

82.

Something

must go wrong, because our +12V supply lead went into flames... Shorted mosfet?

Something

must go wrong, because our +12V supply lead went into flames... Shorted mosfet?

- 30.11.2009: Hardware debug of midihub board: no failure detected. Board

mounted again. Functions o.k. but speed will have to be limited. Also there

is a bug in the PIC software, since the motor speed control (midi controller

82) works the other way round. Mounting of the yellow SMD-LED strip under

the vorsetzer assembly. This is mapped on midi note 127, tested o.k. Start

construction of the damper bar from hard brass. The mounting is not without

problems because the M10 bolts holding the vorsetzer are in the way of the

four M6 bolts required for adjusting the damper bar.

- 01.12.2009: Construction of precision mounting blocks in hardwood to facilitate

allignment after disassembly of the vorsetzer. Further study of the damper

bar construction problem. Felt strip cut out (12mm thick, 30mm wide) and glued

to the brass damper holder with polyurethane glue. Adjustment must be done

with the 4 M6 nuts.

- 02.12.2009: M10 kogelkoppen ingekocht voor montage en vastzetten van de

vorsetzer. Bouten vervangen door M10 x 30 exemplaren. Oud tremulant windgat

gedicht met een messing ornamentje, vastgezet met siliconen rubber. Aanpassing

van het GMT test en stuurprogramma door Kristof Lauwers.

- 03.12.2009: Considering some frontal ornamental parts to break the strong

horizontalism of the automate. Construction of the cable guide on the backside

from stainless steel L profile 20x20x3. This part is removable and fixed to

the side bows with two M6x16 inbus bolts. Finalisation of the single standing

leg: welding of a 30x10x80 standing plate on the 25mm tube, glueing of a 7mm

thick hard rubber pad underneeth. Pic-spec file updated for Johannes Taelman.

- 04.12.2009: Wooden wings sawn out for the front: derived from the original

knee-swell levers. These are functional in that they prevent damage on the

keys in transportation, as the keyboard sticks out slightly from the base.

Decided to add a stainless steel arc to connect both bows on the side. In

common consent with Troy Rogers, Moniek Darge, Kristof Lauwers and more collaborators

and users here at Logos. A spherical mirror will also be added to the motor

underneeth.

- 05.12.2009: Update of the test software in GMT. Construction of the arc.

- 06.12.2009: Further tests under software control. HarmO played the complete

Goldberg Variations today... Return springs added to the registers. Great

discovery: it is possible to remove the reeds without dismantling the entire

automate. However, we need to design a special tool, a reed-puller, first.

- 07.12.2009: HarmO demonstration for my collaborators at Logos.

- 08.12.2009: Whilst I'm trying to trace a reed extractor for HarmO, Troy

Rogers started exploring the almost newborn robot.

- 09.12.2009: <harmO> weighted: 115kg.

- 10.12.2009: Construction of a tool to extract the reeds for tuning and maintenance.

- 11.12.2009: Cleaning out of non-speaking reeds. Sysex lookup tables programmed

by Kristof Lauwers. To use this velocity scaling, send a program change command

with value 122.

- 12.12.2009: Waiting for Johannes for further work on the PIC firmware...

New doppler-sonar gestrobo study written, including <HarmO>: 'Far stars

fade with spectral shifts'. Will be premiered on december 17th by Dominica

Eyckmans and myself.

- 15.12.2009: PIC works with Johannes: bugs in boards 1 and 6 repaired. Inverted

PWM on tremulant motor corrected. First version firmware for the pulse board

(#8): the lights are all implemented now.

- 16.12.2009: Redump sysex lookups for boards 1 and 6. Adjustment of the register

springs and solenoid trajects by Troy Rogers. Yvan Vander Sanden and Troy

Rogers are writing a piece for <harmO>, to be premiered tomorrow! Rehearsal

of the interactive piece with Dominica Eyckmans. Blue LED spotlite added and

mapped on midi note 119.