| " Harma" |

|

Godfried-Willem RAES 2000 archival webpage |

| " Harma" |

|

Godfried-Willem RAES 2000 archival webpage |

A computer controlled acoustic harmonium with touch control and individual registration. The starting point for this construction was an old Hamilton suction reed organ, of which we only kept the reeds and the key springs. A new electric compressor was added (a small Laukhuff Ventola, rated for 50mm H2O pressure and 1000l/m). Since this compressor was pretty noisy in operation we designed a special silencer around it.

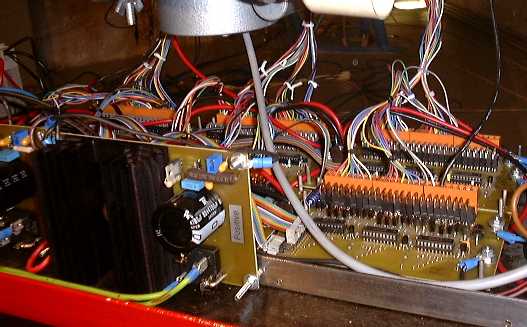

To control the individual reeds we used Laukhuff pallet electromagnets, rated 12V / 160mA each, as shown on the picture below, taken in an early phase through the building of this automate.:

As usual in our instrument

designs, we designed a welded frame for the entire magnet and electromechanical

assembly. Since there is no keyboard we could lower the force required to push

the pallets from the original value of 2.45 to 2.94 Newton to about 1.2Newton.

Since the magnets are wider then the distance between keys/pallets , we had

to mount them on alternating rows. The types we used are 20mm wide. The two

registers are each divided in a bass and a discant unit. So we provided also

control for these 4 registers. This was implemented using solenoids with variable

voltage, such that gradual changes ('expression') becomes very well possible.

As usual in our instrument

designs, we designed a welded frame for the entire magnet and electromechanical

assembly. Since there is no keyboard we could lower the force required to push

the pallets from the original value of 2.45 to 2.94 Newton to about 1.2Newton.

Since the magnets are wider then the distance between keys/pallets , we had

to mount them on alternating rows. The types we used are 20mm wide. The two

registers are each divided in a bass and a discant unit. So we provided also

control for these 4 registers. This was implemented using solenoids with variable

voltage, such that gradual changes ('expression') becomes very well possible.

As a little extra we added a real cast bronze bell as well as a few lights to the mechanism

The note range of the instrument is 29 to 89 expressed in midi notes. The finished instruments has following dimensions: depth 320mm, width 920mm, height 1000mm. The weight is ca. 50kg.

For the electronic control of this instrument we used our own <GMT> software in combination with the hardware we designed for player pianos. Thus the instrument is played using a Wintel Pentium PC. Of course the instrument can also play standard midi files. Not only can it listen to midi commands, but also it can listen to UDP/IP commands in a networked context. The demultiplexer for the parallel input coming either from a standard printer port , a National Instruments DIO device, or a USB interface looks like:

As to the useful National Instruments devices , we have tested hardware and software with both the NiDAQ DIO-24 card and the DAQCard 6533. We designed a small adapterboard to turn these outputs into something looking like a printer port. In 2002 we added a board such that Harma can now also be controlled using a USB board. In fact, this became the preferred interface since. The note driver board and the velocity control circuitry was build after following schematics:

[comment on these circuits, first developed for our player piano can be found at/kursus/2116.html.]

Module 3: 'Harma'

Tessituur: 29 (Fa) - 89 (Fa) [ 5 oktaven ]

Hiervoor werd uitgegaan van een oud Hollands harmonium (gebouwd in Terneuzen eind 19e eeuw (Firma Camphens) , maar voorzien van een mechanisme, balg en rieten van James Baillie Hamilton (Massachusetts,USA)). Het instrument is voorzien van twee onafhankelijke reeksen doorslaande tongen en werkt met zuiglucht, zoals het gros van de Amerikaanse 'reed organs'. De balgen en windlade waren in een dermate wormstekige staat dat we ze helemaal verwijderden. Voor de windvoorziening gebruikten we een Laukhuff Ventola zuigblazer. (1000l/minuut, bij 50mm H2O druk). Daar dienden we wel een goede geluidsdemper voor te ontwerpen want geruisloos zijn deze Ventola blazers bepaald niet... Deze module werd voltooid in de maand juni van 2001.

De kracht nodig om een toets

in te drukken in het originele harmonium varieerde tussen 2.45 en 2.94 Newton.

(250gF tot 300gF in oude gewichtseenheden). De veren die de paletten dichthouden

werden in deze kracht tot zowat de helft teruggebracht. Daardoor konden we met

orgelventielmagneten van de firma Laukhuff (12V/ 160mA) net uitkomen voor een

volledige aansturing. De terugkeerveren werden van deze magneetventielen verwijderd.

De kracht nodig om een toets

in te drukken in het originele harmonium varieerde tussen 2.45 en 2.94 Newton.

(250gF tot 300gF in oude gewichtseenheden). De veren die de paletten dichthouden

werden in deze kracht tot zowat de helft teruggebracht. Daardoor konden we met

orgelventielmagneten van de firma Laukhuff (12V/ 160mA) net uitkomen voor een

volledige aansturing. De terugkeerveren werden van deze magneetventielen verwijderd.

Hartafstand tussen de bedieningspallen voor de rieten was 13.54mm, waardoor we de magneten om en om (in twee rijen) dienden te monteren. Wanneer we de bedieningsmagneten om en om monteren, mogen ze hooguit 27mm breed zijn. De gebruikte types zijn 20mm breed. Voor deze montage bouwden we twee lijsten uit vierkant staalprofiel 16x16. Hierop werden de elektromagneten met parkerschroeven vastgezet en uitgelijnd.

De registers zijn telkens gedeeld in bas- en diskant. Voor de automatisering daarvan gebruikten we aanvankelijk vier stappenmotoren, maar dit werd later -omwille van de snelheid- vervangen door een mechanisme met sterke elektromagneten (15Newton). Voor de 'expressie' -hier met een eenvoudige cylindrische afschermkap uitgevoerd, zullen later wellicht twee stappenmotoren ingezet worden.

Voor de elektronische besturing gebruikten we ons eigen ontwerp voor muziek automaten. Daardoor kon ook aanslaggevoeligheid worden geimplementeerd. Hoogst ongebruikelijk voor een harmonium. De midi kommandos voor deze module moeten naar een Wintel PC worden gestuurd (via midi-in) en worden via de parallelle poort van die PC naar onze specifieke hardware verstuurd en vertaald. De software is een van de vele toepassingen van ons <GMT> projekt. Uiteraard kan de module ook algoritmisch vanuit dezelfde PC worden bestuurd en geprogrammeerd. Het instrument is volledig polyfoon, dus alle toetsen kunnen gelijktijdig en onafhankelijk van elkaar worden ingedrukt en bestuurd. De windvoorziening is evenwel niet toereikend om een volledige kluster weer te geven.

Sedert 2002 kan <Harma> eveneens via USB of rechtstreeks met UDP/IP kommandos vanuit een netwerk worden aangestuurd. Dat is zo'n 300 maal sneller dan bij gebruik van midi.

Ook hier voorzagen we in een kleine spielerei als toevoeging: in dit geval een bronzen klok (F#) die als slagwerk eveneens via de software kan worden bespeeld.

|

Tech-Specs -----------------------------------------------Technische specifikaties: Aanvang bouw: februari 2000 - afgewerkt: 2 juni 2001 Size-----------------------------------------------------------------------------------------------------------Afmetingen van het afgewerkte instrument:

Power--------------------------------------------------------------------------------------------------------Stroomvoorziening:

Insurance value (for organisors):

Rental / concerts:

|

|

Midi Implementatie: The default midi channel for <Harma> is set to 10 (if counting channels from 1, otherwize, 9)

When using UDP/IP for steering <Harma>, the same command set is used through a UDP port. |

exported functions in our dll libraries g_nih.dll or g_noh.dll: Harma_Note (note AS BYTE, velo AS BYTE)

Harma_Reg (register AS BYTE, onoff AS BYTE)

Harma_Motor (onoff AS BYTE)

Harma_Stac (note AS BYTE, velo AS BYTE)

Harma_Bell (velo AS BYTE) Harma_Light (number AS BYTE)

Harma_Listen ()

Harma_PWM ()

|

| Johan Sebastian Bach: | Goldberg Variationen (available on CD in a limited edition LPD-001 ('minus 1') | |

| Das Wohltemperierte Klavier | ||

| Tango's | La Cumparsita Tango | |

| El choclo Tango | ||

| Jealousy Tango | ||

| Uno | ||

| Godfried-Willem Raes | <Harm> for Harma | 2001 |

| 2001 | ||

| <Charms> for Harma | ||

| <Vibes> for Vibi, Piperola and Harma | 2001 | |

| <Trio Paradiso>, for Vibi, Harma and Klung | 2001 | |

| <Paradiso>, for automat orchestra and backing vocals | 2001 | |

| <Tekne>, for automat orchestra and devils dance | 2002 | |

| <Eary Lis Trimbl>, for automat orchestra and musicians | 2002 | |

| <Flexes>, for automat orchestra and musicians | 2003 | |

| <Wandern>, for radar controlled automat orchestra and dancer | 2003 | |

| Kristof Lauwers | <Sonata>, for automat orchestra | 2002 |

| Sebastian Bradt | <Dedication Harma> | 2004 |

| <Early Messages> | 2004 |

| (Terug) naar logos-projekten: projects.html

Back to logos projects |

Terug naar Logos' index-pagina

back to main index |

Naar Godfried-Willem Raes personal homepage...

back to Godfried's page |

Naar katalogus instrumenten gebouwd

door Godfried-Willem Raes

back to catalogue of instruments by Godfried-Willem Raes |

Service manual & detailed circuit and maintenance documentation

Following information and documentation is not intended for the general public.

Harma should be controlled by a PC (from a pentium 120MHz machine on, running Windows98 or Windows 2000 or any later version). If you want to use the printerport, you cannot run under Windows NT or 2000. National Instrument cards and boards for digital I/O can be used. We have tried DaqCard 24 DIO as well as the 6533 Cards and PCMCIA devices. Use NiDAQ version 6.9. Keep the cables between the PC and Harma reasonably short, since too long cables may cause data errors.

Since 2002, we also implemented USB controll for Harma. Use the AW-USB device. This works also under XP. In 2004 we rewrote the driver software completely to obtain a faster response. The new driver works only with USB ports.

Switching <Harma> on:

The following order must strictly be obeyed or severe harm to the instrument will result:

1.- switch on inverter, if the inverter is connected at the same time to a mains voltage supply, it will function as a UPS. If the inverter becomes the source of the mains voltage to <Harms> a buzz may be audible. It is caused by the filter coils in the mains filter at the input of the instrument. It is also possible and allowable to directly feed harma with the mains voltage, bypassing the inverter altogether. In that case connect the power lead directly to the mains voltage input on the instrument.

2.- Make sure the toggle switch for the solenoid power is in the OFF position. Switch on main power for Harma. This causes the 5V power to come up. The display will light up.

3.- start the computer and make sure the printer port is connected to the <Harma> parallel input.

4.- start <GMT>, compilation for Harma (g_robots.exe). Select the midi-in port that will we used to connect to the midi-out from your sequencing program. Select any midi output device that is NOT the one you will you in combination with the sequencing program.

5. in the <GMT> cockpit, start application and set all notes to off.

6. switch on the solenoid power supply on Harma: now the red and blue LED's should come up.

7. for GMT applications: start whatever piece from the computer.

8. for playback of midi files: start your sequencing program after activating the midi-listen task in the <GMT> cockpit.

Circuit boards overview:

All solenoids have a common positive voltage connection. The second wires come together in Weidmueller 8-pole connectors (two for each set) to the note hold and velo boards. To get access to the reeds and the springs, first disconnect all these connectors. Next, remove the U-shaped stainless steel protectors. Then loosen the bolts joining upper and lower part of the instrument. The solenoid assembly can be lifted up vertically from the soundboard containing the reeds. Always keep components in a horizontal position!

The positive voltage can be adjusted on the power supply printed circuit board with the multiturn trimmer. The voltage should be adjusted such that when no velocity pulses are applied, the solenoids develop just enough force to push the pallets down and hold them down. Initially we found 16V to be a suitable setting. The negative voltage should be adjusted between 20V and 48Volts. Initially we had it set to 23V. Changing this voltage will change the velocity scaling of the instrument.

Technical revisions and maintenance notes:

The <Harma> automat can be heard on the Logos Public Domain CD <Automaton> (LPD007). It is also a part of the <M&M> robot orchestra and as such in can be heard on Logos Public Domain CD <M&M> (LPD008) and LPD013. We also recorded a full CD with J.S.Bach's Goldberg Variations, interpreted by Harma. Available on request from the Logos Foundation.

In 2004/2005 two CD's in the same LPD series appreared: LPD013 (Machine Orchestra) and LPD014, (Robody) each featuring pieces wherein Harma plays an important role.

Last update: 2005-07-12 by Godfried-Willem Raes