|

|

|

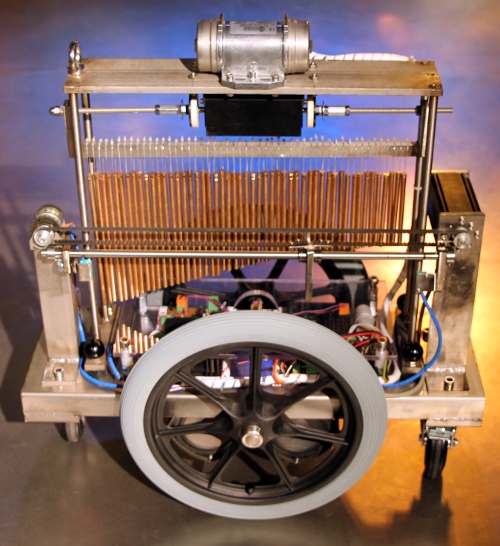

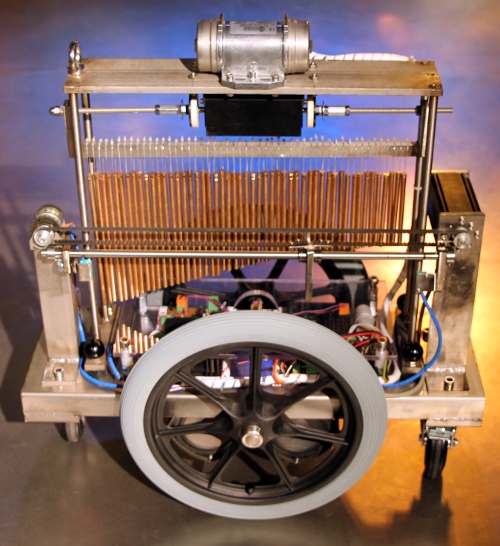

<Chi>

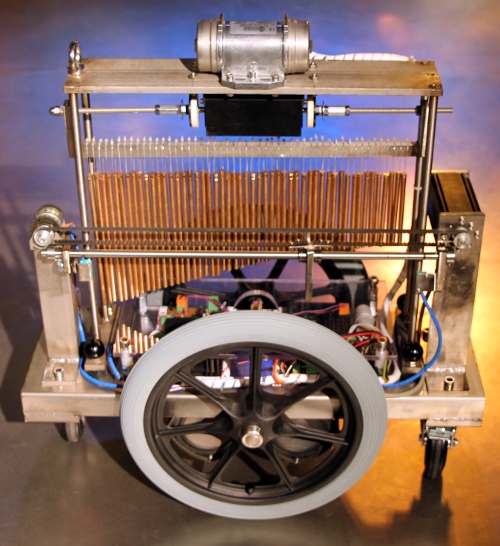

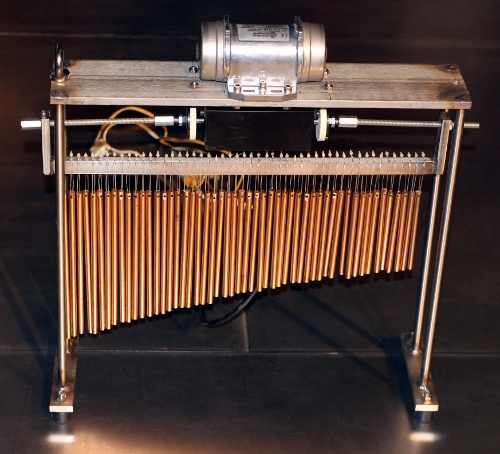

automated orchestral chimes

dr.Godfried-Willem

RAES

2016

|

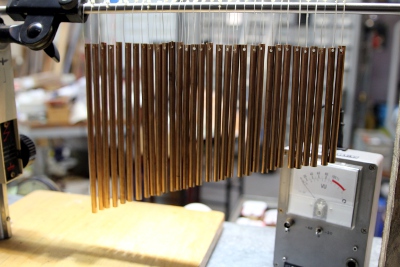

Orchestral chimes are a relatively new addition to the gamut of orchestral

percussion instruments. They entered our orchestras in the early seventies of

the 20th century. Generally they are made from aluminum staff material, in rods

of ca. 6 to 8 mm in diameter. The number of chimes in a set ranges between 28

and up to 42. One of the main considerations in the design of this robot was

to build it from materials we had in stock. The reason being that in the period

of its conception and construction, we suffered from very serious insecurities

with regard to the funding of the Logos Foundation by the Flemish government.

So we had to avoid any kind of extra expenses.

From an acoustical point of view, orchestral chimes behave as freely vibrating

rods. For our instrument we used bronze, mainly for the greater clarity of sound

and the much larger ultrasonic spectrum. The fundamental resonant frequency

of these rods is inversely proportional to the square of the length of the rod:

With: f= fundamental frequency

in Hz, L= length of the rod, k=diameter of the rod, Q= modulus of elasticity,

r= density of the material. (Olson, p.77). The overtones are a non-harmonic

series, given in the literature as:

With: f= fundamental frequency

in Hz, L= length of the rod, k=diameter of the rod, Q= modulus of elasticity,

r= density of the material. (Olson, p.77). The overtones are a non-harmonic

series, given in the literature as:

- f1 = 2.756 f0

- f2 = 5.404 f0

- f3 = 8.933 f0

Excitation of the chimes can be achieved in three different ways:

- 1.- by shaking left/right of the entire chime assembly. This is implemented

with a large bi-directional solenoid.

- 2.- by vibrating the assembly in a front/back motion. This is implemented

with a motor driven vibrator. This gives a quite rich sound cloud.

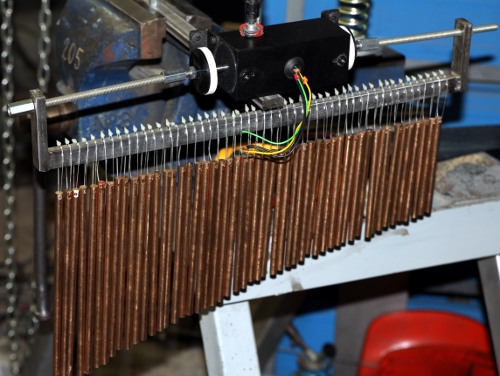

- 3.- by striking the rods with a metal bar left to right and reverse. This

is implemented with a servo motor driven linear motion mechanism. This gives

the traditional 'glissando effect'.

All different modes of excitation can be combined freely.

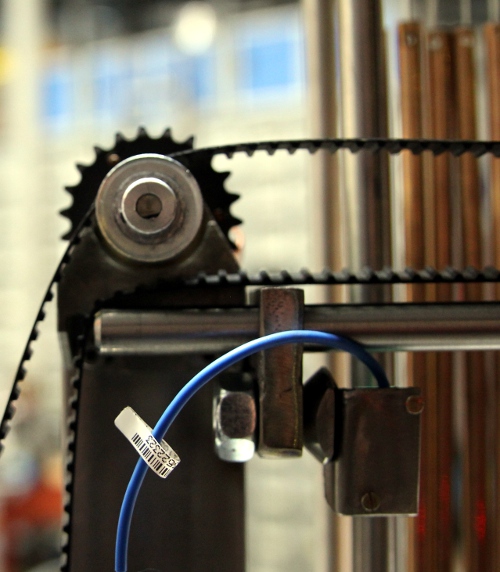

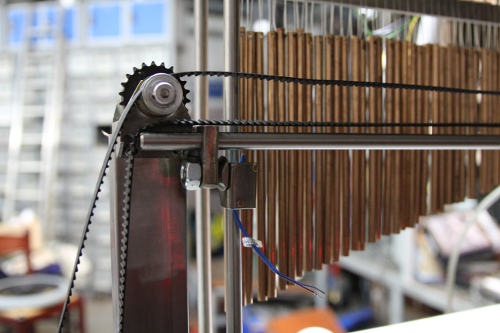

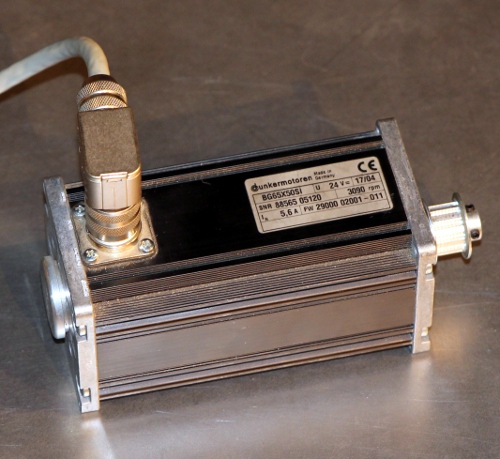

For the linear motion, we used a Dunkermotor, type BG65x50SI, rated for 24

V operation. Nominal rpm for this motor is 3090, as this, if it were to drive

a threaded rod (M10 thread) directly, would lead to a pretty slow linear motion

in the order of 10 seconds for the full glissando, we used a dented belt mechanism

between the motor and the rod. Proximity sensors are mounted on both ends of

the striking mechanism. The motor can be speed controlled and can move to the

left or to the right. However, jumping from one spot to another is not possible.

On reaching either end position, the motor will stop automatically. It is up

to the user to reverse the direction of rotation. A command to make the motor

move and go over and back between two given positions is also implemented. On

cold boot, the robot will always perform a calibration and than return to the

extreme left position. Users should never move the motorised slide by hand,

as doing this will invalidate the calibration. Note that fast changes of motor

speed may cause motor stalling and should be avoided.

We did not provide in a damping mechanism for the chimes. Thus users are warned

that the sound may go on for much longer than the actual duration of the excitation.

Just like in the case of our <Tinti> robot, a nice and original feature

here again is that the sounds it produces are extremely high pitched and their

spectral components extend well into the ultrasonic range. We measured sound

pressure levels up to 114 dBC in the frequency range between 25 and 35 kHz.

(Note that the dBA scale cannot be used, as this is corrected for the characteristics

of the human ear). This opened a wealth of musical possibilities when used in

combination with our ultrasound based

invisible instrument technology. In fact, the sensors we developed capture

the ultrasonic components of the chimes very well and, due to the demodulation

circuitry, can be brought into the audible range and even be modulated through

gesture and movement. Quite magic in fact.

The idea behind the technology being very similar, the implementation for <Chi>

however, came out quite different than what we did for <Tinti>. First

of all, we used the PIC microprocessor on the midihub board to generate ultrasonic

frequencies in the range 16 kHz to 38 kHz. The frequency can be modulated on

the fly using pitch bend commands. The amplitude of the ultrasonic carrier signal

used for demodulation can be controlled with controller #8. However, other than

in <Tinti>, here we feed the ultrasonic carrier frequency directly into

a multiplier circuit, thus circumventing the problem of finding suitable wide

band ultrasonic transducers. Thus we perform frequency demodulation on the ultrasonic

spectral contents of the chimes, transposing them into the audible range. If

this feature is enabled on the <Chi> robot, the audible result is that

all difference tones between the carrier frequency and the ultrasonic components

of the chimes become audible through the build-in speakers. Although this robot

has indeed a pair of loudspeakers, it should not be considered an electronic

instrument at all, as all sound produced is inherently acoustic. By modulating

the carrier frequency, pitch shifts of the chime sounds become possible. The

effect is quite mesmerizing.

A final remark: as this robot makes use of ultrasonic frequencies it may show

interference with our ultrasound based gesture sensing technology, as the acoustic

frequencies used could interfere with the invisible instrument used for gesture

recognition. So composers should make sure they test their concept thoroughly

before attempting to use <Chi> in our sonar based gesture-interactive

environment. If our radar equipment (PicRadar, Quadrada etc...) is used at the

other hand, no interference can occur as its working principle is based on microwaves

and not on sound. The same problem with interference can also happen if the

<Chi> robot is used together with the <Tinti> robot, as <Tinti>

is capable of emitting ultrasound as well.

Only when integrated in the context of our robot

orchestra with its wealth of varied sensor systems allowing full interactivity

with gesture and audio, this automate will become a true robot. That's after

all were its destination is to be sought.

Midi Mapping and implementation:

This is the ambitus for the instrument:

Midi channel: 9 (10 if counting 1-16).

- Note 96: the bronze tine assembly will move to the left. The force is controlled

by the velocity byte.

- Note 97: the bronze tine assembly will move to the right. The force is controlled

by the velocity byte.

- Note 98: the bronze tine assembly will move in alternating directions. The

force is controlled by the velocity byte. If a repetition rate is programmed

using the key pressure command, the over and back movement will continue until

a note off command is received.

- Note 99: The vibrator will be activated. The intensity of the vibrator is

steered by the velo byte. Key pressure can be used for automated repeats.

- Note 100: the motor will run in clockwise direction ( the sledge moves to

the left then) and play the downwards glissando as long as the note stays

on. When the left end position is reached it will automatically stop. The

speed of the movement is controlled by the value of the velocity byte. The

left end position can be controlled with controller #74.

- Note 101: the motor will run in counter clockwise direction (the sledge

moven to the right) and play the upwards glissando as long as the note stays

on. When the right end position is reached it will automatically stop. The

speed of the movement is controlled by the value of the velocity byte. The

right end position can be controlled with controller #75.

- Note 102: the motor will move over and back between the positions set with

the controllers #74 and #75. If these controllers are not sent, the movement

will use the entire trajectory. The maximum speed of the movement after the

ramping is controlled with the value of the velocity byte. Whilst the motor

is running, the speed can be changed using the key-pressure command.

- Note 103: will activate the brake. The braking force can be controlled with

the velocity byte. Braking also stops the motor. On reception of a note off

for note 103, the clutch will release.

- Note 120: Red Lite, the velo byte steers the flashing frequency

- Note 121: Red Lite, the velo byte steers the flashing frequency.

- Note 122: Tungsten lights, left and right together. The brightness can be

steered with the velocity byte. Flashing is implemented with the key-pressure

command.

Controller 7: Volume control for the ultrasonic receiver and amplification.

Setting this controller to zero will mute the amplifier.

Controller 8: Level for the ultrasonic carrier wave. This works by PWM on the

carrier wave (range 0-50%). The effect is not spectacular, but using lower settings

helps to reduce the spikes in the bell sounds. With a setting to maximum, the

duty cycle will be 50% and the waveform symmetrical and reasonably sinusoidal..

With low values for this controller, leak through of the carrier frequency,

if this is set to values within the human perception range, can be minimized.

Controller 30: sets the repetition rate for all components that have auto-repeat

implemented, including the lights.

Controller 31: can be used to shift the frequency range

of the carrier frequency in chromatic steps as shown in this table:

| Value |

base frequency |

midi note |

note name |

| < 39 |

21096 Hz |

136 |

E |

| 39 |

2489 Hz |

99 |

Eb |

| 40 |

2637 Hz |

100 |

E |

| 41 |

2794 Hz |

101 |

F |

| 42 |

2960 Hz |

102 |

F# |

| 43 |

3136 Hz |

103 |

G |

| 44 |

3322 Hz |

104 |

G# |

| 45 |

3520 Hz |

105 |

A |

| 46 |

3729 Hz |

106 |

Bb |

| 47 |

3951 Hz |

107 |

B |

| 48 |

4186 Hz |

108 |

C |

| 49 |

4435 Hz |

109 |

C# |

| 50 |

4698 Hz |

110 |

D |

| 51 |

4978 Hz |

111 |

Eb |

| 52 |

5274 Hz |

112 |

E |

| 53 |

5587 Hz |

113 |

F |

| 54 |

5920 Hz |

114 |

F# |

| 55 |

6272 Hz |

115 |

G |

| 56 |

6644 Hz |

116 |

G# |

| 57 |

7040 Hz |

117 |

A |

| 58 |

7458 Hz |

118 |

Bb |

| 59 |

7902 Hz |

119 |

B |

| 60 |

8372 Hz |

120 |

C |

| 61 |

8870 Hz |

121 |

C# |

| 62 |

9397 Hz |

122 |

D |

| 63 |

9956 Hz |

123 |

Eb |

| 64 |

10548 Hz |

124 |

E |

| 65 |

11175 Hz |

125 |

F |

| 66 |

11840 Hz |

126 |

F# |

| 67 |

12544 Hz |

127 |

G |

| 68 |

13289 Hz |

128 |

G# |

| 69 |

14080 Hz |

129 |

A |

| 70 |

14917 Hz |

130 |

Bb |

| 71 |

15804 Hz |

131 |

B |

| 72 |

16744 Hz |

132 |

C |

| 73 |

17739 Hz |

133 |

C# |

| 74 |

18794 Hz |

134 |

D |

| 75 |

19912 Hz |

135 |

Eb |

| 76 |

21096 Hz |

136 |

E |

| >76 |

21096 Hz |

136 |

E |

If any controller value setting in the midi note range higher than note 127

is send (controller values > 67) , the blue LED on the demodulation board

will light up. The actual frequency generated will always be the base frequency

with the 14-bit value send with the pitch shift command added. The default value

for this controller is 76. The formula for calculating the frequency of the

emitted sound is: f = (2489 * 2^((CC31 - 39)/12)) + (pbmsb * 128) + pblsb, wherein

CC31 is the setting for controller 31 within the limits 39 to 76, pbmsb the

7-bit value sent with the pitchbend command and pblsb the low 7-bit value of

the pitchbend command.

Controller 65: Mute switch for the amplifier section. Value 0 mutes the amplifier,

any other value will turn it on.

Controller 66: Robot on/off switch. Sending this controller with value zero

will power down the robot and reset all controllers to their default value.

The glissando motor will return to its default extreme left position if it wasn't

there already. The amplifier will be muted.

Controller 70: Calibrates the movement motor position and brings it to a left

position. This command should only be sent on a full stop of all motors, i.e.

no other midi motor related commands should be sent during this calibration.

The parameter can be any non-zero value. This calibration also takes place automatically

after a cold start of the robot. Do not use this controller in any sequenced

composition. If the motorised sledge has been moved by hand with the robot turned

on, this command must be send in order to recalibrate the positions.

Controller 71: implemented for hardware debugging: Motor OFF. Do not use this.

Controller 72: implemented for hardware debugging. Absolute

run clockwise. Do not use this.

Controller 73: implemented for hardware debugging. Absolute

run counterclockwize. Do not use this.

Controller 74: sets a left side start or end position for the motor carriage.

By default this controller is set to 0, corresponding to extreme left.

If a value is given larger then the setting for controller #75, the robot will

correct this and set the controller to the value for controller #75 minus one.

On reception of this controller the motor will

move to the position given by the value of the parameter.

Controller 75: sets a right side start or end position for the motor carriage.

By default this controller is set to the extreme right if calibration was performed.

This setting may be smaller than 127. If a value for this parameter is send

smaller then the value for controller #74, the robot will correct this and will

set the controller to the value for controller #74 + 1. The setting for the

right side position must always be larger then the position for the left side.

The minimum value for this controller is 1.

Controller 76: sets the ramping speed for motor acceleration. Default startup

value = 64. Minimum value =1. Note that ramping is never applied to slowing

down.

Controller 123: All notes off, preserving controller settings and motor position.

The motor will be halted.

Pitch bend: used to modulate the ultrasonic carrier wave. (All 14 bits are

used as a unipolar unsigned 14 bit value). The frequency can be controlled between

basefrequency (by default 21096 Hz) and basefrequency + 16384. So the upper

limit for the ultrasonic frequency is 37480 Hz. With CC31 set to 39, the lower

limit is 2489 Hz.

Status indicators on the PCB's:

- Ultrasonic microphone board:

- The vertical LED-bar serves as a VU meter.

The lowest bar

should never lite up, as this indicates saturation of the pre-amp.

- Ultrasound demodulation board:

- Red LED: Processor watchdog. This LED flashes on/off at a rate of ca.

0.75 Hz

- Blue LED: This led will be on as soon as the demodulating signal is

ultrasonic (> 20 kHz)

- Green LED: This LED follows the power on/off status. When controller

#66 is set to ON, this LED will be on.

- Yellow LED: If this LED is off, the amplifier is muted. If on, the audio

system is turned on. The LED follows the status of controller #65.

- Motor controller board:

- Red LED: Processor watchdog. This LED flashes on/off at a rate of ca.

0.75 Hz

- Blue LED: Flashes as the position of the motor driven slide changes.

- White LED: this LED is always on when the 5V processor voltage is present.

Technical specifications:

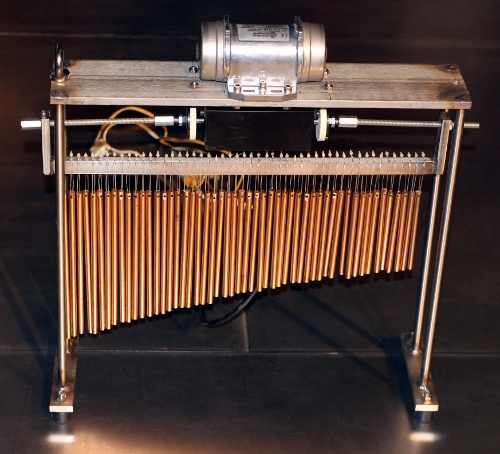

- size: width 560 mm, height 500 mm, depth 200 mm

- weight: 40 kg

- transportation: needs a flightcase.

- power: 230 V ac / 165 W (peak, normal playing less than 50 W)

- Ambitus: untuned.

- control: MIDI-input, 3 MIDI-Thru, differential. (UDP/IP Ethernet port to

be implemented later)

- loudness: <=98dBA at 1m distance.

- Insurance value: 11.500 Euro

Design and construction: dr.Godfried-Willem

Raes

Collaborators on the construction of this robot:

- Mattias Parent ( mechanics, PCB drilling, workshop assistant)

Music composed for <Chi>:

Godfried-Willem Raes:

'Namuda Study #60 : The Passion of Chi' (2016)

Kristof Lauwers: new piece including Chi (2016)

Kristof Lauwers: 'Picradar Study for Chi' (2016)

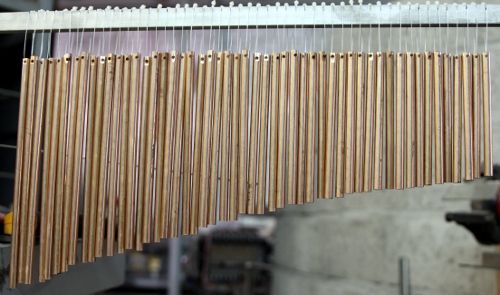

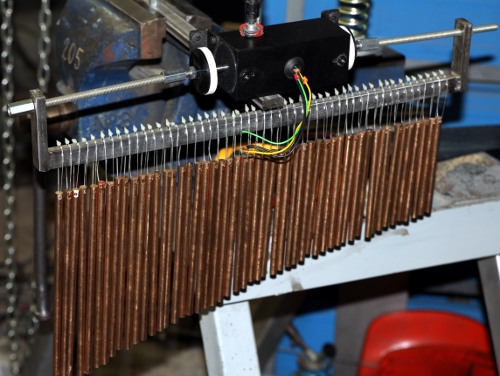

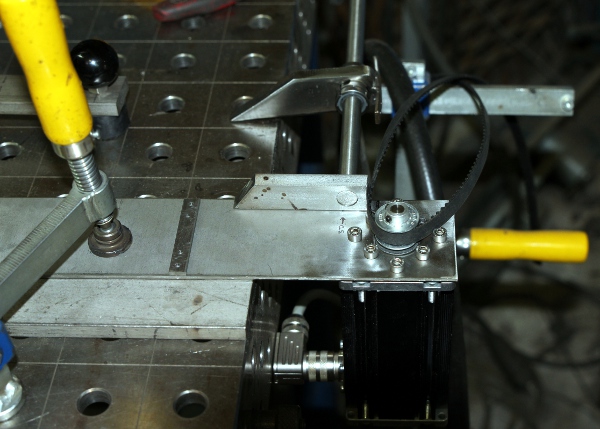

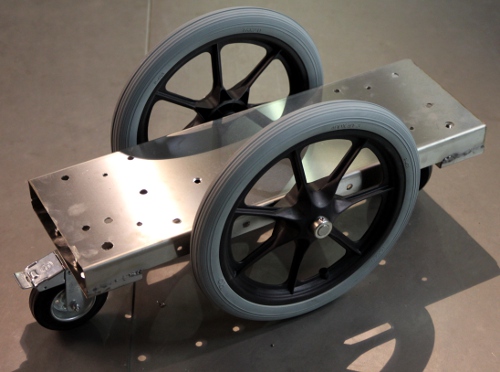

Pictures taken during the construction in our workshop (in chronological

order):

Robodies picture with <Chi>:

[waiting for nude model candidates]

Construction & Research Diary:

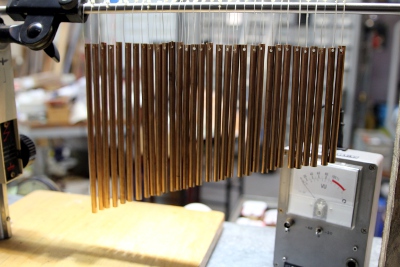

- 28.02.2016: Start construction of a set of chimes from bronze staff material.

- 29.02.2016: Measurements on the ultrasonic power spectrum performed.

- 01.03.2016: 43 tone rods cut and drilled. Lengths varying between 240 mm

and 120 mm. This gives a range of four octaves.

- 02.03.2016: design of a suspension bar. Distance between rods taken as 9

mm. This gives us a 1 mm space between the rods. Experiments carried out with

a large fan in order to find out in how far it would be possible to agitate

the chimes with wind. Result: possible, but at the required wind-speed, the

fan becomes way too noisy.

- 03.03.2016: Experiments with a motor driven vibrator (Italvibras). Number

of chimes augmented to 51. Construction of the suspension staff: stainless

steel 500 x 10 x 25, with slots 0.8 mm wide on 9 mm distance between slots.

First tests with a Laukhuff bi-directional solenoid, same type as used for

<Klung>.

- 04.03.2016: Construction of the upper mounting plate: stainless steel 500

x 100 x 10. This plate holds both the bi-directional solenoid as the vibrator

motor. Welding works: vertical poles are 450 mm long, 12 mm diameter, these

are strongly welded on the upper plate as well as on the base strips (30 x

10 x 160).

- 05.03.2016: Research and measurement of the ultrasonic spectrum of the chimes.

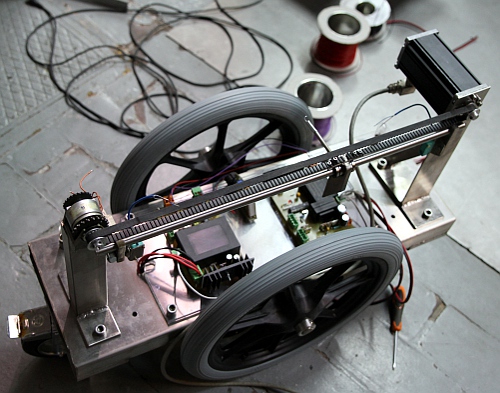

Design of a motorized striking rod for linear motion. Here we could use an

M10 threaded rod with a high nut. The speed is 1.5 mm / rotation. Hence for

the 50 cm trajectory, 333 rotations are required. If we use a 3000 rpm motor,

the whole trajectory would take about 10 seconds.

Not

really fast... Anyhow the use of a DC motor seems mandatory here. A stepper

would be way to noisy here.

Not

really fast... Anyhow the use of a DC motor seems mandatory here. A stepper

would be way to noisy here.

- 06.03.2016: Experiments with a Dunkermotor servo, type BG65x50SI.

Maybe a bit overkill, taking into account the price being far over 1000 Euro...

First version for a control board using an 18F2525 microcontroller. In any

case, two microcontrollers will be required as we are in need of at least

3 PWM channels. For the end-sensors we can make use of two Pepperl-Fuchs NAMUR

proximity sensors, type NJ 2-V3-N. These can be powered from 5V directly,

although this is lower then the 8.2 V after the NAMUR specification. We used

then in earlier robots such as <Korn> as well.

Maybe a bit overkill, taking into account the price being far over 1000 Euro...

First version for a control board using an 18F2525 microcontroller. In any

case, two microcontrollers will be required as we are in need of at least

3 PWM channels. For the end-sensors we can make use of two Pepperl-Fuchs NAMUR

proximity sensors, type NJ 2-V3-N. These can be powered from 5V directly,

although this is lower then the 8.2 V after the NAMUR specification. We used

then in earlier robots such as <Korn> as well.

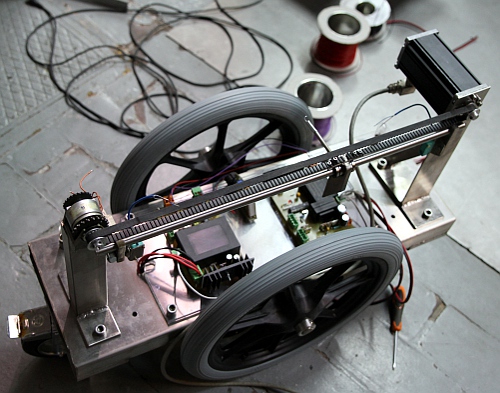

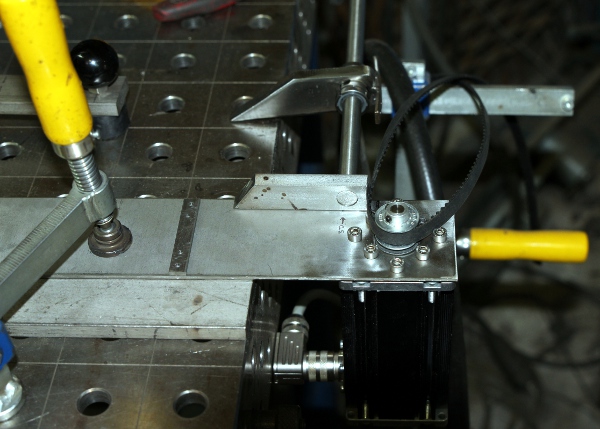

- 07.03.2016: Alternative design worked out for the horizontal movement: a

spindle, 12 mm, with a linear ball bearing sliding over it and driven via

a dented belt would allow for movement speeds at least a factor 20 faster

than in the threaded rod approach.

The

Dunkermotor can still be used in this design. Detailed technical drawing of

the mechanical construction, scale 1:1. First prototype of the linear motion

mechanism welded in stainless steel.

The

Dunkermotor can still be used in this design. Detailed technical drawing of

the mechanical construction, scale 1:1. First prototype of the linear motion

mechanism welded in stainless steel.

- 08.03.2016: Cutting of the bottom mounting plate. Delivery of 24 V / 6 A

power supply and solid state relays from Farnell. Welding of the slide assembly:

The distance between

bottom plate and center of excitation point for the chimes determined and

fixed to 220 mm. For the non-motorised side of the spindle we mounted a solenoid

operated clutch with ball bearings. It's a part we recycled from an old photocopier.

It will allow us to perform easy braking in the movement.

The distance between

bottom plate and center of excitation point for the chimes determined and

fixed to 220 mm. For the non-motorised side of the spindle we mounted a solenoid

operated clutch with ball bearings. It's a part we recycled from an old photocopier.

It will allow us to perform easy braking in the movement.

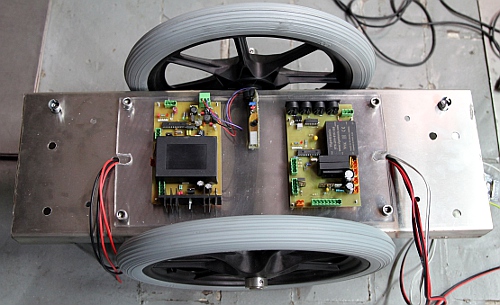

- 09.03.2016: Design of the ultrasonic demodulation board. There are some

major improvements in this design as compared to what we did for <Tinti>.

For the volume control, here we are using a second AD633 multiplier wired

as a VCA. Start of the design of the PCB for this circuit.

- 10.03.2016: Design for the ultrasound demodulation board finished. No response

yet from ILP with regard to our order. Are they going out of business?

- 11.03.2016: Design of the hub and motor control PCB. Welding works on the

motor stand.

Calculation

of a suitable wheel base.

Calculation

of a suitable wheel base.

- 12.03.2016: Looks like ILP Electronics Ltd. is out of business. This means

we have to redesign the PCB and circuit for the demodulation board. The TDA7264

looks like an easy candidate for the substitution. It's a 2-channel chip rated

for 2 x 15 W. This could be the new circuit:

An extra feature here is the addition of a mute circuit, controlled by a PIC

port. Also, since it's a 2-channel chip without facilities to use it in bridge

mode, we will connect two small loudspeakers on the outputs. PCB board for

this design drawn out. This is ready for production now. TDA7264 chips ordered

from Farnell.

An extra feature here is the addition of a mute circuit, controlled by a PIC

port. Also, since it's a 2-channel chip without facilities to use it in bridge

mode, we will connect two small loudspeakers on the outputs. PCB board for

this design drawn out. This is ready for production now. TDA7264 chips ordered

from Farnell.

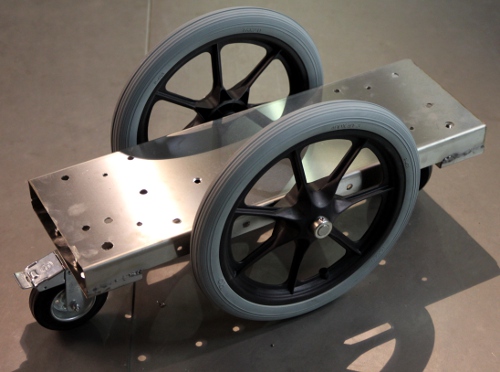

- 13.03.2016: Construction of the wheelbase. Axle for the 400 mm diameter

spoke wheels is 20 mm. The smaller pivoting wheels have 120 mm diameter and

a building height of 160 mm. Drawing and construction of the mounting plate

for the two SMPS modules as well as the IEC power entry with switch. This

plate mounts with four M8 bolts to the main chassis.

- 14.03.2016: Design and construction of the mounting plate for the transducers.

This plate connects to the main chassis with 4 countersunk M8 x 16 bolts and

nuts on the backside of the robot. Start wiring of the power supply assembly.

Welding of the wheelholder plates to the main chassis. Mounting of the wheels.

Test of the movement.

- 15.03.2016: Bulb sockets mounted on chassis using Parabond. The TDA7264

audio amplifier chips came flowing in from Farnell. Exposure, development

and etching of the PCB's. Start soldering of the hub and motor control board.

Around midnight we had both PCB's assembled...

- 16.03.2016: Hardware testing and checking. Demodulator board thoroughly

tested and firmware version 1.0 written and debugged. Some minor bugs in the

hardware solved. Testcode added to our GMT software. <Chi> is fully

implemented now as a member of the robot orchestra. A pair of new encapsulated

squawkers digged up and tested. Philips AD50600/SQ8. Here is a picture:

Real

vintage items as they were produced in 1972. They have been living on our

shelves since then... Eight standoff tubes cut from brass, 102 mm long. Mounting

will be done with M4 threaded rods.

Real

vintage items as they were produced in 1972. They have been living on our

shelves since then... Eight standoff tubes cut from brass, 102 mm long. Mounting

will be done with M4 threaded rods.

- 17.03.2016: Firmware for the demodulator board improved. Now version 1.1.

Mounting of the loudspeakers on the backplate. Cutting of the polycarbonate

mounting plate for the PCB's and the ultrasonic microphone. Start wiring of

the components mounted under the main chassis plate.

- 18.03.2016: Mounting of the loudspeaker assembly. Mounting of the PCB's

on the polycarbonate plate. Mounting of the motor mechanics on the main chassis.

Start wiring of the boards. This is the wiring diagram for the motor and hub

board:

- 19.03.2016: Further wiring of the <Chi> robot. Running out of 2-pole

Weidmueller connectors as well as shrink tube... Missing components ordered

from Farnell. Start writing the firmware for the motor and movement control

board.

- 20.03.2016: a full day of debugging the firmware for the motor board. Not

working yet!

- 21.03.2016: Set rings placed on the horizontal slide, one side flattened.

Further work on the motorboard firmware. Waiting for connectors and shrink

tubing, ordered from Farnell.

- 26.03.2016: Missing parts came in. Continuing work on the wiring. First

firing up of the robot... no smoke stacks in any case. Placement of the motor

AC capacitor (0.8uF/ 450V ac). Observing a nasty sound from the +5V/3A power

supply module on the hub board, the pitch changing with the load... This SMPS

module is produced by Vigortronics (VTX-214-015-105)... Shame over them.

- 27.03.2016: Further work on the assembly. First tests. US-demodulation board

fully saturating and even motorboating... The amplifier mute function works

well though... The lights do work as expected.

- 28.03.2016: Hardware debug of the demodulation board: pin 1 on the first

multiplier needs a DC return to ground: 10 k SMD resistor soldered on the

copper side. Same problem for pin 3 on the second multiplier: 18k resistor

soldered in. Motorboating problem remedied by placing a 4.7 Ohm resistor in

the +15 V line to the analog processing circuitry. Circuit drawing updated

accordingly. Sofar, this part of the robot seems to work quite well and as

expected. However we meet a problem with the +5 V/3 A power supply on the

motor board as it gives off sounds that get picked up by our microphone, get

demodulated and give a most disturbing varying pitch on the output... Testing

the motor board revealed following problems and deficiencies: the Laukhuff

solenoid works very well but needs rescaling of the velocities. The vibrator

motor works fine, but here also some rescaling might be required. The clutch

works fine, but has intermittent glitches. Either the connector is shaky,

or a bleeding resistor over the high voltage capacitor is required. Checks

revealed the connector (a French make...) was shaky. The Dunkermotor for the

slide mechanism remains fully dead... A deep going debug is required. The

position pulse counter works and the motor does not give an error signal.

The maximum DC voltage we get on the speed input is 7.8 V, well within specs.

- 29.03.2016: No matter what we try, the Dunkermotor (type BG65x50 SI, serial

number 88565 05120) remains dead. Would it have been too near to my welding

works? It does not give out an error message... We made a special manual control

board, but even with this it does not give a kick.

At

startup, connecting the 24 V power supply, it draws some 280 mA current and

the shaft feels slightly locked. After a few seconds, the current falls back

to 20 mA and the shaft is fully released. Seems the Dunker motors are now

distributed by Eriks. Alternative 5 V SMPS power supply modules ordered from

Farnell. The Vigortronics type is trashworthy. Shaking mode and vibrator demonstrated

with the nicely working ultrasonic demodulation for Luk Vaes and Kristof Lauwers.

At

startup, connecting the 24 V power supply, it draws some 280 mA current and

the shaft feels slightly locked. After a few seconds, the current falls back

to 20 mA and the shaft is fully released. Seems the Dunker motors are now

distributed by Eriks. Alternative 5 V SMPS power supply modules ordered from

Farnell. The Vigortronics type is trashworthy. Shaking mode and vibrator demonstrated

with the nicely working ultrasonic demodulation for Luk Vaes and Kristof Lauwers.

- 30.03.2016: Work on the horizontal striking mechanism. Construction of a

polycarbonate cover plate. Fastening bolts and nuts. Visually it looks ready

(almost) now...

- 31.03.2016: Further work on the firmware: scalings for the Laukhuff solenoid

(now 10 to 60 ms), flashing for the tungsten lites implemented. 5 V Vigortronix

power supply module replaced with Traco Power type TML05105. This type fits

on the PCB. Autorepeat implemented also for the vibrator motor. Firmware flashed

and tested o.k. Polycarbonate upperplate bolted on with M10 x 40 bolts and

Epramid standoff's.

- 01.04.2016: Extensive testing under GMT control. Measurement of the loopspeed

-and thus the timing resolution- of the firmware in the motor control board:

11.7 us or 85.47 kHz. On heavy loads this value can reach a maximum of 14.2

us. (Tektronix TDS2024C measurement).

- 02.04.2016: Starting to write a Namuda Study demonstrating the wide range

of possibilities of the new robot.

- 03-04.2016: further application code development. Specific library functions

for <Chi> added to our g_file.dll library.

- 05.04.2016: Refinement of the slow PWM coding for the vibrator motor. Now

the pulse duration range is 20 ms to 100 ms, measured and verified on the

TDS2024C. Idealy, the motor control should take the phase of the mains voltage

into account. To avoid firmware complexity, it would be better to provide

in a microcontroller just to generate mains-voltage independent signals, 90

degrees phase shifted. Thus we could leave out the large AC capacitor form

the motor circuit and steer the motor with variable frequency directly.

- 06.04.2016: Further testing of useable ranges for controllers.

- 07-10.04.2016: Composition of the first gesture interactive piece for <Chi>"

'Chi's Passion'. Discovered that the vibrator can cause the midi connector

to come loose... If that happens, the robot is out of control of course...

- 17.04.2016: First rehearsals of 'Chi's Passion' with Dominica Eyckmans.

- 18.04.2016: Construction of a sturdy stud for the backside of the Dunkermotor,

as this one tends to resonate dangerously much when the vibrator is turned

on. The support mounts on the back motor flange with four M4 bolts. It is

clamped to the motor holder base with a single M6 x 40 bolt.

- 19.04.2016: Awaiting delivery of the new Dunker motor...

- 20.04.2016: Rehearsal for Chi's Passion with Dominica Eyckmans. The nylon

straps do tend to break off. We will have to round off the sharp edges on

the suspension slots.

- 21.04.2016: Premiere performance of Chi's passion as well as a new piece

by Kristof Lauwers, including Chi.

- 27.05.2016: The new Dunker motor came in. Problem: the mounting holes are

different from those on the original motor, so we will have to change the

holding chassis accordingly.

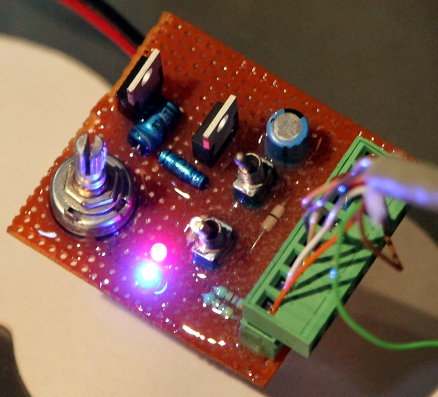

- 06.06.2016: Further work on the Dunker motor failure. Looks like the controll

signals for the Dunker motor BG65x50SI have to be 24V and not 5V TTL! (this

is contrary to what it says in the manual though). So, a modification on the

PCB will be required. We designed a simple logic level shifter as follows:

We mounted it

on a small piece of breadboard. The board accomodates two level shifters as

these are required for both the cw and the cww input to the Dunker motor.

First tests carried out with the original motor, as very likely there is nothing

wrong with it... and indeed, the motor is o.k. Now we can go on fine tuning

the firmware for the motor control...

We mounted it

on a small piece of breadboard. The board accomodates two level shifters as

these are required for both the cw and the cww input to the Dunker motor.

First tests carried out with the original motor, as very likely there is nothing

wrong with it... and indeed, the motor is o.k. Now we can go on fine tuning

the firmware for the motor control...

- 07.06.2016: Further firmware development on Chi: Motor controller.

- 08.06.2016: Finally got it working! Version Chi_Mot V1.1 flashed into the

motor PIC. Awaiting user feedback now.

- 09.06.2016: Lookup tables for Dunker motor speeds added in the firmware.

Firmware version is now V1.2 Adding ramping in the firmware implemented for

acceleration only, is still an open option. Chi demonstrated for our Berlin

guests.

- 10.09.2016: Working on motor firmware version 1.3, with ramping implemented.

Controller #76 added to make user control of ramping speed possible. Ramping

is only applied to speed up, as for slowing down and stopping, a mimimal ramping

function is implemented in the hardware (0.2s).

- 11.06.2016: Further debugging and smoothing of the motor control firmware/

- 12.06.2016: Firmware version 1.4 for the motor PIC flashed.

- 18.07.2017: <Chi> used in the orchestration of our Erik Satie 'Parade'

production.

- 24.07.2017: <Chi> added in the orchestration of 'Summer' in Godfried-Willem

Raes' Symphony #3.

- 23.10.2020: <Chi> gets an important role in our Ukiyo-E production.

- 22.01.2021: <Chi> found to be vandalized, despite our warnings: "The

placement of the midi I/O connectors behind the back wheel, is awkward. We

advize users to use an angled DIN connector here. Never lead the midi cable

through the wheel spokes." The reason for this warrning became very clear

now... Repair of the midi-hub board required.

- 23.01.2021: Midi hub board repaired and modified: now the midi-in cable

goes into the PCB vertically. To make this possible, we drilled a large hole

in the polycarbonate cover plate above the PCB's. Also we removed one of the

midi thru connectors, so now Chi only has two functional balanced midi thru

outputs.

- 23.06.2023: The hex-inbus bolts securing the dented drive wheel on the motor

came loose. This was the cause of irregular and erratic behavior of the slide.

Also the sensors were found to be loose. Tightening all bolts solved all reported

problems. Ultrasonic demodulation system checked and found o.k.

- 08.11.2023: Two tines got loose and fell out. We replaced the nylon straps.

<Chi> works fine again and joins in the performance of my 4th symphony.

TO DO:

- This robot became ready on june 12th 2016. However, it was already presented

to our audience, April 21st 2016 at the occasion of the Logos Robot Orchestra

concert that evening.

- Construction of a flightcase with a clamp for the tines.

Last update: 2023-11-08

by Godfried-Willem Raes

The following information is not intended for the general public nor for

composers wanting to make use of our <Chi> robot, but is essential

for maintenance and servicing of the robot by our collaborators. It also

might be useful as a source of inspiration for people that want to undertake

similar projects. Our designs are not copyrighted but placed into the public

domain, thus copying designs is allowed, provided the source is always explicitly

credited and referred to. Feedback is mostly welcomed.

Technical drawings, specs

and data sheets:

Power supplies:

- +5 V DC - 2 A (Logic, led-lights and microcontrollers, mounted on the

hub and motor control board. Traco Power, type TML05105)

- +15 V-0- -15 V DC - 1 A for ultrasonic demodulation circuitry and amp.

(Traco Power SMPS, type TMM40212) (mounted on the ultrasound and amplifier

board).

- +24 V - 6.3 A (SMPS XP-Power, type LCL150P24) [mounting: 4 M4 x 8 bolts]

- +48 V - 2.3 A (Sunpower SMPS, tpe SPS-S100-48) [mounting: 3 M3 x 6 bolts]

Bronze alloy used for the tone rods: Cu Pb 10 Sn, s.g.= 9.1 kg/dm3 (DIN

1716), ordered from Demar Lux bvba.

- Motorvibrator:

- Italvibras M20, Farnell order nr. 7035123, 22 VA - 230 V, phase shift

capacitor: 0.8 uF/ 450 V ac

- http://www.italvibras.it

- Linear motion:

- Dunker servo motor: BG65x50SI (24 V, 100 VA, 70-4000 rpm) [907 Euro,

purchased in 2003]

- dented drive wheels: CTB12037ALU

- dented belt: Gates powergrip 037 672 XL

- linear ball bearing: STAR Linear bushing 0612-012-10 (Deutsche Star

Gmbh, D-97419 Schweinfurt)

- spindle: Stainless steel 12 mm diameter, polished.

- end sensors: NAMUR, Pepperl-Fuchs NJ2-V3-N (read as analog voltages,

the output not being TTL compatible)

-

Bi-directional solenoid: August Laukhuff, kleiner trakturmagnet.

Ultrasound components:

- Circuit drawing for the ultrasound receiver board (designed 2001):

- The PCB for this circuit:

- Demodulator circuit:

- PCB for this board:

- Firmware for this board: Chi_US.bas,

hex dump for this firmware: Chi_US.hex

- Motor control and midihub board:

- Firmware for this board: Chi_Mot.bas,

hex dump of the firmware: Chi_Mot.hex

- PCB for this board.

- Light bulbs:

- 24 V, controlled by the motor board (dimmable, tungsten light bulbs,

note 122)

- 24 V, red LED strips controlled by the demodulator board (notes 120,

121)

With: f= fundamental frequency

in Hz, L= length of the rod, k=diameter of the rod, Q= modulus of elasticity,

r= density of the material. (Olson, p.77). The overtones are a non-harmonic

series, given in the literature as:

With: f= fundamental frequency

in Hz, L= length of the rod, k=diameter of the rod, Q= modulus of elasticity,

r= density of the material. (Olson, p.77). The overtones are a non-harmonic

series, given in the literature as:

An extra feature here is the addition of a mute circuit, controlled by a PIC

port. Also, since it's a 2-channel chip without facilities to use it in bridge

mode, we will connect two small loudspeakers on the outputs. PCB board for

this design drawn out. This is ready for production now. TDA7264 chips ordered

from Farnell.

An extra feature here is the addition of a mute circuit, controlled by a PIC

port. Also, since it's a 2-channel chip without facilities to use it in bridge

mode, we will connect two small loudspeakers on the outputs. PCB board for

this design drawn out. This is ready for production now. TDA7264 chips ordered

from Farnell. Real

vintage items as they were produced in 1972. They have been living on our

shelves since then... Eight standoff tubes cut from brass, 102 mm long. Mounting

will be done with M4 threaded rods.

Real

vintage items as they were produced in 1972. They have been living on our

shelves since then... Eight standoff tubes cut from brass, 102 mm long. Mounting

will be done with M4 threaded rods.

We mounted it

on a small piece of breadboard. The board accomodates two level shifters as

these are required for both the cw and the cww input to the Dunker motor.

First tests carried out with the original motor, as very likely there is nothing

wrong with it... and indeed, the motor is o.k. Now we can go on fine tuning

the firmware for the motor control...

We mounted it

on a small piece of breadboard. The board accomodates two level shifters as

these are required for both the cw and the cww input to the Dunker motor.

First tests carried out with the original motor, as very likely there is nothing

wrong with it... and indeed, the motor is o.k. Now we can go on fine tuning

the firmware for the motor control...