Rotomoton

automated percussion

Version 1.0 - archive file

2000/2006

This instrument is a computer controlled assembly of five rototoms. Each drum is equiped with beaters and the pitch of each rototom can be controlled. The lowest couple of rototoms have 3 beaters each, whereas the upper three suffice with two beaters each. The beaters are velocity sensitive and have full 16 bit dynamic control. Heavy duty stepping motors are used to achieve pitch control of each individual drum. Instead of rotating the drums on their fixed axis, we fixed the frames of the drums and rotate the threaded axis through a geared construction using dented belts. This also contributes to silent operation of the mechanics.

The instrument can be played by standard MIDI commands, straigth or using our GMT software in which case it is also capable of listening to pure algorithmic commands, bypassing the inherent slowness and low dynamic/timing resolution of the midi protocol. Particularly precize control of stepping motor movement and hence, pitch changes of the drums, requires a very high data rate impossible to achieve using midi.

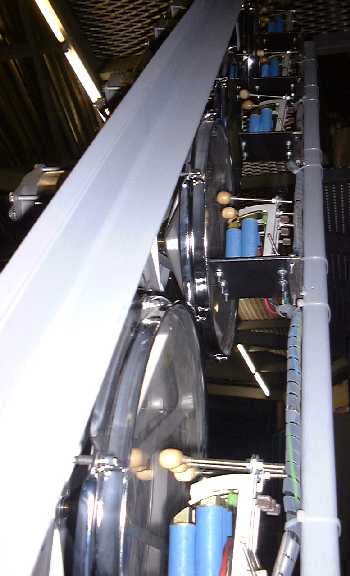

The picture above gives an idea of the construction of the beater side of <Rotomoton>. The construction of two of the five stepping motors can be seen on the picture below. The picture was taken with the position sensors rermoved.

<Rotomoton> uses dedicated hardware, designed for musical automats such as player pianos, percussion instruments, organs and even bowed instruments. Details can be found in our course on experimental music on this same website.

The original (version 1) hardware consisted of following printed circuit boards:

1. a parallel bus-board, designed for many of our automated instruments. (cfr. Klung, Player Piano, Harma, Springers, Troms, ThunderWood, Gorgel, Troms...) This board gets its input from a parallel printer port or from a National Instruments DIO device (PCI card or PCMCIA card) from a stardard wintel PC running Window98 with MMX command set and multimedia timer features. Under Windows NT or Windows2000, only the NiDAQ version should be used. However, it is also possible to use any other microprocessor or controller as long as it can implement centronics like outputs. The pc board for this circuit contains the 5V regulator used for the digital signal sections on the other logic boards as well. To see this circuit, a demultiplexer, click following link: bus-board schematic

Two bits of the velo-bus are used to select the timer chips for the beaters, the note bus is used to drive the individual coils of the stepping motors as well as the DAC's used for pulse width modulation for tuning the rototoms. The lights are also controlled by the note bus.

2. Beater driver board. This pc board houses the power mosfets used to steer the solenoids used for activating the sound sources. In this instrument we used individual programmable 16 bit timers for each beater. The timer chips used are Intel 82C54 types. [ comment on these circuits, first developed for our first generation player pianos can be found at http://www.logosfoundation.org/kursus/2116.html. ]

3. The power mosfets we used for controlling these solenoids are Harris

RFP4N12L (equivalent to IRL640), since these switch on TTL levels and

are capable of dissipating the required currents. Note that when the power

suppy is switched on, all latches may go to a high state, thus sounding

all notes at the same time. To avoid this, either first start the computer

and the appropriate GMT program and then switch on <Rotomoton>,

or start Rotomoton with the provided dummy connector inserted in the input

port.

4. The stepping motors use special circuitry, shown below. Since in this

application, very high force but no holding torque is required from the

steppers, we designed the circuit as a single pulse driver. The pulsewidth

for the pulse applied to successive windings is software programmable.

(range about 2 to 23 ms). Since the motor current can be quite high, the

mosfets (RFP10N15L types) had to be mounted on individual heatsinks. Therefore

they could not find a place on the board but are mounted on a large discrete

panel under the motors directly. The mosfet assembly together with a motor

can be seen on the picture, although the heatsinks are masked by one of

the contruction bars.:

The dented wheels are selected as follows:

| motor shaft number of teeth | drum axis wheel number of teeth | belt type | maximum stepfrequency | nr. of motor steps required for one revolution of the drum axis | |

| smallest drum (Sop) | 12 | 42 | 220XL | 500Hz | 700 |

| second drum (Mez) | 12 | 48 | 180XL | 450Hz | 800 |

| third drum (Alt) | 12 | 48 | 200XL | 450Hz | 800 |

| fourth drum (Tenor) | 12 | 60 | 220XL | 350Hz | 1000 |

| fifth drum (Bass) | 12 | 72 | 210XL | 350Hz | 1200 |