|

<HAT>

|

|

a hit any thing percussion robot

Godfried-Willem

RAES

2009

|

The design of this musical robot started with a request from Aphex Twin. After

some exchange of ideas, we agreed to undertake the task of designing a musical

robot that could be used to strike just about anything. For technical and physical

reasons however it is impossible to realize this in its full generality. The

mass of the striking object always has to be in proportion to the mass as well

as the magnitude of the spring-force behaviour of the object struck. Big objects

require big beaters to obtain a big sound, put it simple words. Hence in our

design we decided to foresee a variety of different beaters and mechanisms such

that for a wide variety of objects, a suitable beater can be found in the robot.

A strict condition for the robot to function properly is that the object struck

should always be clamped ridgidly to the structure. If the struck object is

allowed to move even slightly, precise control of the striking forces and hence

of the musical dynamics, becomes unpredictable if not impossible. The largest

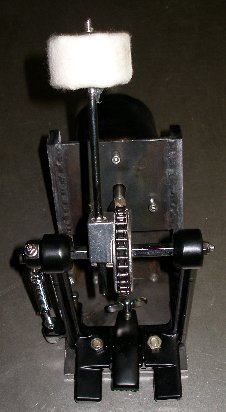

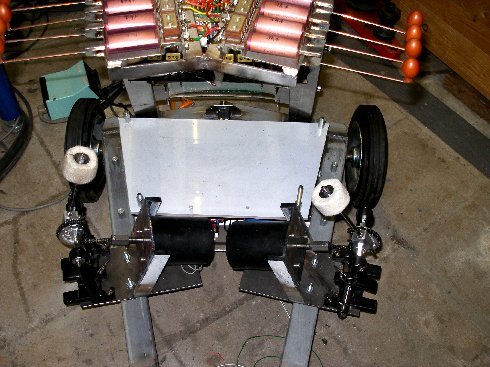

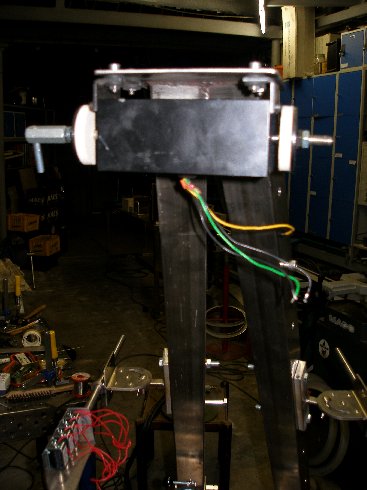

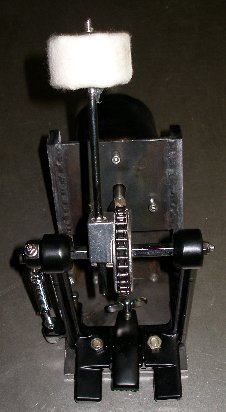

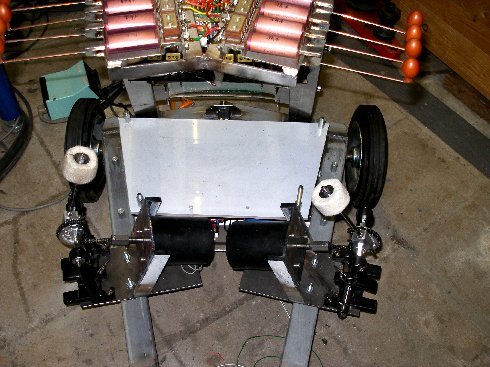

beaters are driven by very large and heavy solenoids driving a bass-drum kind

of mechanism. They can be used for objects such as gongs, bass drums, heavy

metal plates etc. These mechanisms are mounted near the base of the robot on

both the right and left sides. The traditional footstepplate disappeared altogether

in our pedal design, where the solenoid pulls the chain driving the rotating

beater mechanism directly.

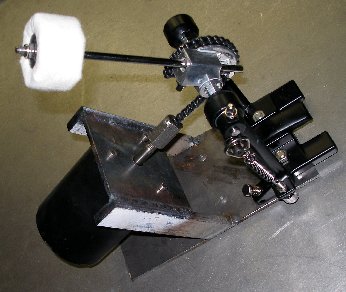

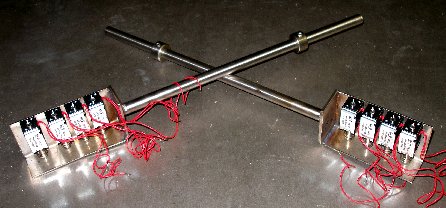

Also on the bottom structure we mounted two rotary solenoids to be used for

objects/instruments placed on the floor. Two 'hands' with four 'fingers' each

are designed to make very fast rolls possible. These mechanisms are mounted

on adjustable slides in the upper part of the robot. They are similar in function

and operation to the beaters we designed for <Snar>,

our snare drum playing robot.

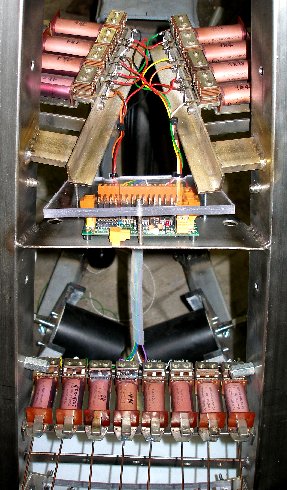

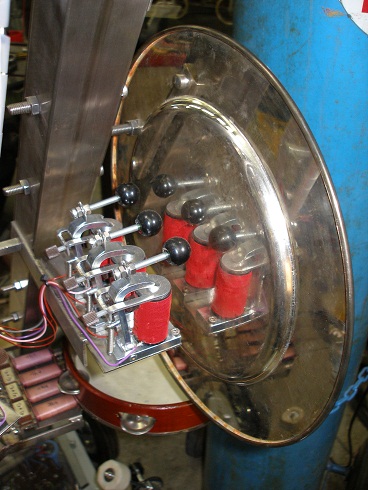

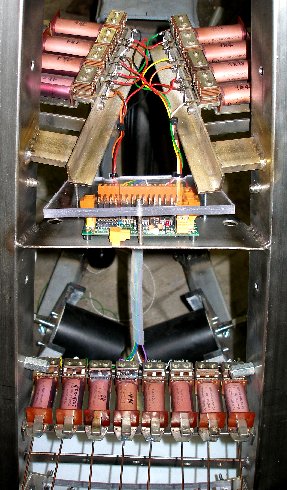

Two sets of three beaters operate in a vertical plane. These use a similar

technology as well as the same type of solenoids, as we designed in earlier

robots such as <Xy> or <Tubi>.

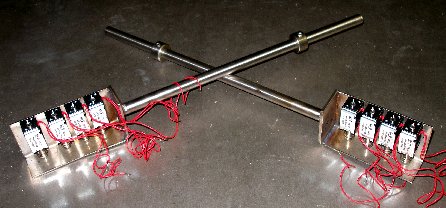

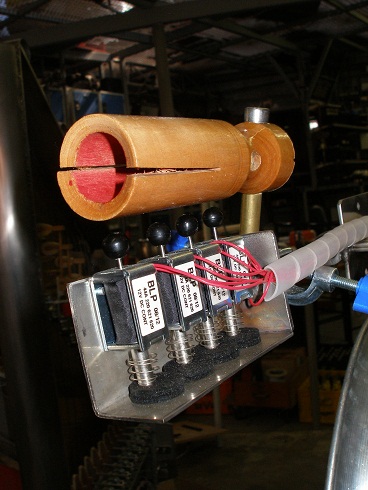

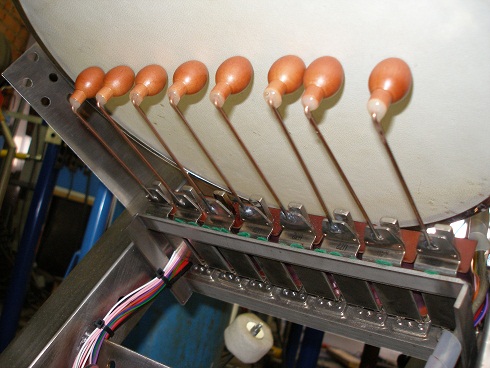

Sixteen beaters (two sets of four and one set of eight) make use of modified

relay solenoids. These can operate pretty fast and are very suitable for rolls.

The tips of these beaters are made of exotic wood.

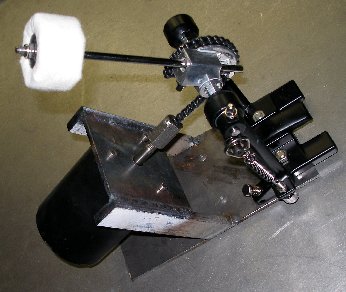

Two beaters, mounted on the underside of the robot make use of rotary solenoids

and can be adjusted in position. They are meant to beat objects placed on the

floor. When moving or transporting the robot, these mechanisms have to be brought

in an upward position such as to avoid damage during handling and transportation.

Next to the beater mechanisms, we could not resist in providing also a shaking

mechanism. This idea builds further on the experiences gained during the construction

and use of our earlier <Thunderwood> (this

one has wood chimes and a large thundersheet) and particularly the <Psch>

robot. The last one uses only shaking mechanisms.

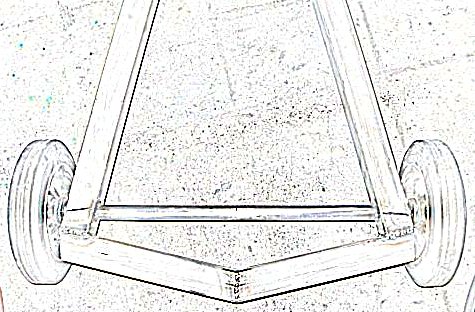

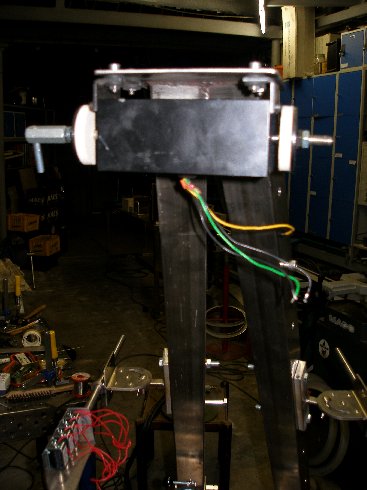

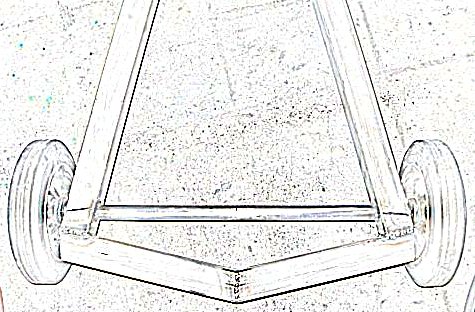

The chassis and troley for this robot was made of very sturdy steel in order

to be free of own resonances and unwanted noises. The structure was designed

such that the stand-off from ground level becomes 100mm, thus making it possible

to have the robot hit objects arranged on the floor. The heavy

duty wheel base is a welded construction made from ST42 steel, whereas for the

upperpart stainless steel AISI304 or AISI316 is used.

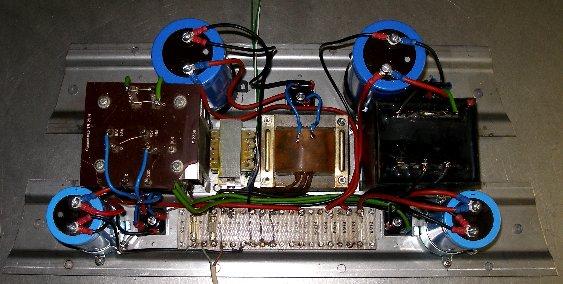

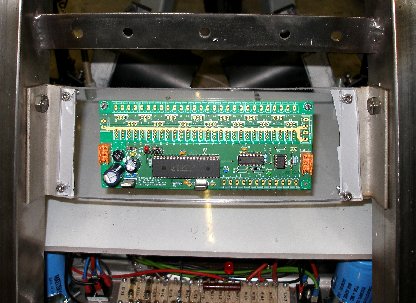

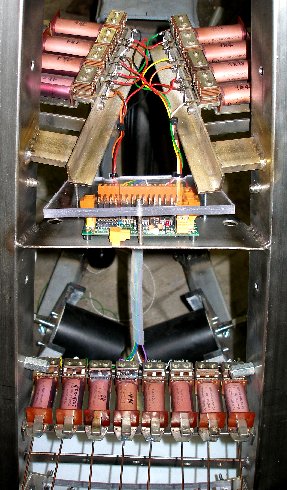

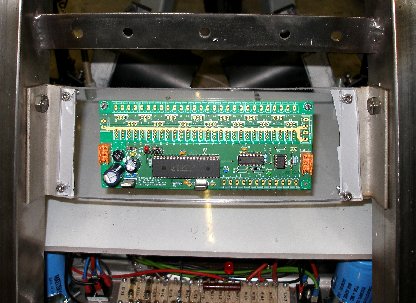

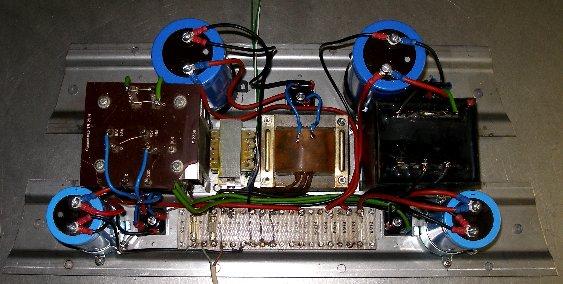

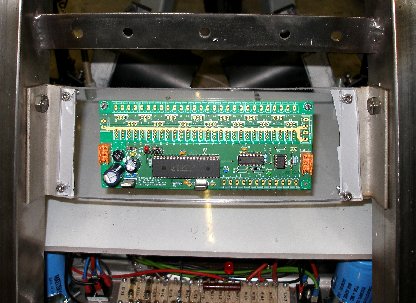

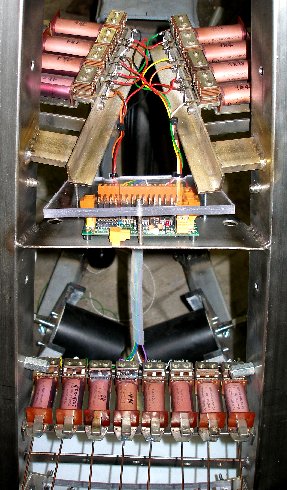

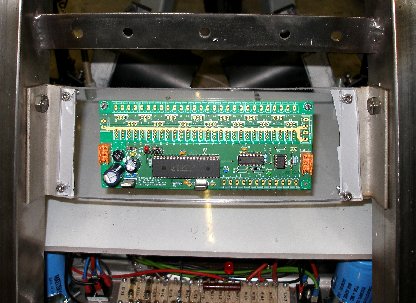

The entire circuitry for this robot makes use of a few fast

PIC controllers: One Microchip PIC 18F2525 and one Microchip PIC18F4620 - I/SP

types. The timing resolution, essential to obtain a good velocity sensitivity,

is extremely high (in the order of 20 microseconds). The circuits are visible

in the robot assembly but protected with a transparant polycarbonate cover.

To remove dust from the circuits, compressed air (2 Bar pressure is enough)

should be used.

The <Hat> robot has following exciters fully implemented::

- 2 very heavy duty beaters, with exchangeable beater heads.

If bass drums are mounted, the two frontal legs should be extended such as

to reach ground level.

- 2 rotary beaters to hit floor based objects, These are not

very fast, but highly visual.

- 8 vertical very fast beaters, oriented upwards to beat objects

in a horizontal plane arranged in two units of 4 solenoids each. ('finger'-beaters,

mounted on pivoting arms)

- 6 horizontal beaters (as used on our xylophone (<Xy>),

beating objects placed in a vertical plane.

- 1 heavy duty shaker (bidirectional solenoid driven).

- 16 small beaters with upward movement. (2 assemblies of 4

beaters on each side of the robot and an assembly of 8 beaters on the back).

In order to conform with electrical safety regulations, the chassis is connected

to mains ground. A grounded power cable should always be used.

Circuit Overview:

High Voltage pulse board:

Midi Mapping and Implementation:

The midi channel for <HAT> is 10 (0-15) or 11(1-16).

| midi note |

object |

repetition rate |

|

Voltage |

wiring PIC |

| 36 |

left pedal |

|

|

100V |

|

| 37 |

right pedal |

|

|

100V |

|

| 38 |

left toes |

|

|

100V |

|

| 39 |

right toes |

|

|

100V |

|

| 40-41 |

shaker (alternate) |

|

|

100V |

|

| 42-43 |

optional expansion |

- |

|

100V |

|

| 48-51 |

left hand |

|

|

50V |

|

| 52-55 |

right hand |

|

|

50V |

|

| 56-58 |

vertical beater left |

|

|

50V |

|

| 59-61 |

vertical beaters right |

|

|

50V |

|

| 62-63 |

optional expansion |

- |

|

50V |

|

| 72-75 |

upwards left |

|

|

200V |

18F2525 |

| 76-83 |

back beaters |

|

|

200V |

18F2525 |

| 84-87 |

upwards right |

|

|

200V |

18F2525 |

| 96 |

light left eye |

|

|

|

|

| 97 |

light right eye |

|

|

|

|

| 98 |

light frontal |

|

|

|

|

| 99 |

light frontal |

|

|

|

|

Midi note range: 36 - 87 ( see table) , velocity implemented . Lights have

no velocity, just on/off.

Note Off commands are not required for the beaters.

Controller 66 is used to switch the solenoid power on or off.

Program Change: implemented to change to different user programmable velocity

scalings and lookup tables

<HAT> responds to the midi all-notes-off command. (Controller 123)

Sysex: implemented for user programmable velocity scalings. Pincodes: hat1,

hat2

Technical specifications:

- size: 1256 mm long, 750 mm wide. heigth 1750mm

- weight: 94 kg

- power: 230 V / 240 V ac - 470 W max.

- Ambitus: see mapping table

- WARNING: operating beaters without objects to be struck may cause permanent

damage to the mechanism.

- Price: ca. 20.000 Euro

Design, research and construction: dr.Godfried-Willem

Raes (2009)

Collaborators on the construction of this robot:

- Kristof Lauwers (2009)

- Yvan Vandersanden (2009)

- Moniek Darge (2009)

- Johannes Taelman (2009)

Some pictures made during the construction, in chronological order:

with some 'anythings' mounted:

with some 'anythings' mounted:

Nederlands:

Robot: <HAT>

Dit is de eerste robot die we op bestelling ontwierpen en bouwden.

De enige tot nu toe die niet wordt ingelijfd in het M&M orkest. De bestelling

kwam van Aphex Twin (alias voor Richard James), die ons aanvankelijk kontakteerde

met de vraag of we niet bereid waren een van onze bestaande robots aan hem te

verkopen... Maar, aangezien alle robotten deel uitmaken van het M&M robotorkest

en ettelijke komposities in hun klinkend voortbestaan afhankelijk zijn van de

volledige samenstelling van dit orkest, weigerden we op die vraag in te gaan.

Na heel wat over en weer praten en onderhandelen, stemden we er

uiteindelijk mee in een speciale nieuwe robot te ontwerpen: eentje die allerhande

objekten en instrumenten zou kunnen aanslaan en tot klinken brengen. Toen we

goed en wel aan het ontwerp begonnen, bleek zo'n min of meer universele robot

algauw onnoemelijk vele problemen met zich te brengen. Immers, algemeen gesteld

moet de massa van het aangeslagen instrument (inklusief de veerkracht ervan)

in verhouding staan tot die van de klopper. Een robot die zomaar op alles kan

slaan is daarom alleen al ondenkbaar. Zelfs wie niet muzikaal technisch goed

onderlegd is zal begrijpen dat je geen triangel kan aanslaan met een paukestok,

zomin als je een bastrom tot klinken kan brengen met het metalen staafje waarmee

de triangel aangeslagen wordt. Om die reden voorzagen we deze robot dan ook

van een grote variatie aan kloppers en elektromagneten zodat voor eender welk

objekt wel ergens een geschikt aanslagmechanisme kan gevonden worden. Dit neemt

natuurlijk niet weg dat het noodzakelijk is om de afstand objekt-klopper al

naar het geval heel nauwkeurig in te stellen en te optimaliseren.

Aangezien een gammele en rammelende konstruktie voor zo'n ontwerp

volstrekt uit den boze is, ontwierpen we voor deze robot een gelast chassis

uit uiterst stevig profielstaal en voorzagen we dit van een onverwoestbaar stevig

wielstel. Daarbij werd voor een driewiel konstruktie geopteerd, omdat zoiets

per definitie altijd stabiel staat. Zoals in vele van onze robots speelt ook

hier weer de hoek van 60 graden een konstruktief zowel als estetisch belangrijke

rol.

Voor het 'pedaal'-mechanisme vertrokken we van het tegenwoordig

gangbare middels een ketting aangedreven tuig. Hiervan verwijderden we de treeplaat

geheel en aktiveerden we het draaimechanisme rechtstreeks via een uiterst krachtige

trekmagneet.

Tessituur en midi mapping:

Bouwdagboek:

- 15.12.2008: eerste ideeen en schetsen. Onderzoek naar de mogelijkheid om

op de vraag van Aphex Twin in te gaan.

- 15.01.2009: Uitwerking van de mogelijkheden en berekening van de technische

implikaties.

- 01.02.2009-17.02.2009: Uitwerking ontwerpschetsen.

- 19.02.2009: start konstruktie van de wielbasis. Voorwiel van 380mm diameter

met massieve band.

- 20.02.2009: Afdraaien van de as en konstruktie van de vork. Ontwerp wielremmen/vastzetters.

- 21.02.2009: TIG laswerk vork voorwiel en vertikale as. Konstruktie van het

remmechanisme. Voorlopige proefmontage van het wiel zelf. Uitwerking lasplan.

- 22.02.2009: Konstruktie achteras. Uitfrezen ovale asgaten. Aanlassen en

uitlijnen 60 graden schuinstaande 50x50 kokerprofielen voor de verbinding

van het frontaal deel met de achteras. Achterwielen diameter 250mm. As 25mm,

asdiepte 65mm.

- 23.02.2009: Laswerk hoofdstruktuur chassis en wielbasis op lastafel. Uittekenen

en narekenen van de hoeken voor de vertikale opstand.

- 24.02.2009: Begin konstruktie draagstruktuur voor de zwaarste elektromagneten

en de pedaalmechanismen.

- 25.02.2009: Konstruktie van de 'vinger'-mechanismen met 8 uiterst snelle

kloppertjes, vertikaal omhoog. Verplaatsbaar middels een massieve geslepen

as van 12mm.

Deze

elektromagneten zijn voorzien van een veer om de terugslag nog te versnellen.

Deze

elektromagneten zijn voorzien van een veer om de terugslag nog te versnellen.

- 26.02.2009: Ontwerp en konstruktie instelmechanisme voor de vingers. Bestelling

van rotary solenoids bij Lucas-Ledex. Eerste tentatieve berekeningen van de

vereiste voedingen. Ontwerp en experimenten met het pedaalmechanisme.

- 27.02.2009: Laswerk pedaalmechanisme. Positionering op het robot chassis.

De beide pedaalmechanismes zijn op het chassis gemonteerd met telkens twee

M8 x 80 bouten. Fotodokumentatie toegevoegd op deze webpagina.

De overbrengingsketting is met een gehard M3 boutje (lengte 20mm) doorheen

de inox lange busmoer vastgezet. Door verdraaing van het anker van de elektromagneet

tegenover de busmoer kan het aanslagpunt van de klopper precies worden ingesteld

en afgeregeld. Funktionele mechanische en elektrische tests van het mechanisme.

De overbrengingsketting is met een gehard M3 boutje (lengte 20mm) doorheen

de inox lange busmoer vastgezet. Door verdraaing van het anker van de elektromagneet

tegenover de busmoer kan het aanslagpunt van de klopper precies worden ingesteld

en afgeregeld. Funktionele mechanische en elektrische tests van het mechanisme.

- 28.02.2009: Uitsnijden van de inox profielen voor de vertikale opstand.

Aanlassen montagehoeken onder 60 graden. Hiermee wordt de uiteindelijke bouwhoogte

bepaald op 1750mm. Proefmontage en beoordeling globale vormgeving.

- 01.03.2009: Perforatie van de vertikale opstanden met gaten om de 50 mm,

dit omwille van de bevestigingmogelijkheden voor 'universele' klankobjekten.

De gaten worden geboord met een 8 mm kobaltboor, wat voldoende sterkte moet

bieden voor allerlei te bevestigen objekten zonder de strukturele sterkte

van de inox profielen in het gedrang te brengen. Ontwerp montagebeugels.

- 02.03.2009: Verdere uitwerking montage mogelijkheden externe objekten.

- 03.03.2009: Een eerste exemplaar van de bestelde rotary solenoids is geleverd.

Het blijkt evenwel veel te klein en te weinig krachtig voor een toepasbaarheid

binnen dit robot projekt.

- 04.03.2009: Ombouw oude industriele telefoonrelais tot elektromagneten en

meting van hun responsiviteit.

- 05.03.2009: Staafjes aangelast op 24 stuks van die oude relais, na wegnemen

van alle schakelkontakten. Kloppertjes kunnen in hardhout gemaakt worden.

- 06.03.2009: Laukhuff magneten geleverd.

- 07.03.2009: Ontwerp draagstruktuur voor de Laukhuff magneten.

- 08.03.2009: Experimentele ombouw telefoonrelais naar kloppertjes. Ze moeten

wel met 200V aangestuurd worden en zijn niet al te snel.

Het eerste ontwikkelde type is voorzien van een relatief zware houten kogel.

Dit werkt maar levert dubbele aanslagen op vanwege de veerkracht van de beide

staafjes waarmee de kogel is bevestigd.

Het eerste ontwikkelde type is voorzien van een relatief zware houten kogel.

Dit werkt maar levert dubbele aanslagen op vanwege de veerkracht van de beide

staafjes waarmee de kogel is bevestigd.

In het tweede proefprojekt

gebruikten we lastoevoegmateriaal van 2.4 mm diameter waarop we kleine houten

langgerokken kogels monteerden.

In het tweede proefprojekt

gebruikten we lastoevoegmateriaal van 2.4 mm diameter waarop we kleine houten

langgerokken kogels monteerden.

- 09.03.2009: Alleen IGBT's zijn eigenlijk bruikbaar om de relais spoelen

op hoge spanning te schakelen. Als type kozen en bestelden we de IRGB14C40LPbF

in een TO220AB behuizing. Dit type heeft immers genoeg aan een gate spanning

van 5V om goed te schakelen. Maximale spanning: 350V, maximale stroom: 14A.,

Dissipatie: 54W. Fabrikant: International Rectifier. We plaatsten de bestelling

bij Farnell.

- 10.03.2009: 32 beaters klaargemaakt als prototype voor verdere beproevingen.

Ontwerp voeding hiervoor. Meetopstelling met IGBT, 1k4 spoel aangestuurd met

4.5V blokpuls op de gate: zonder diode over de spoel kan een repetitiesnelheid

van zeker 16Hz (24Hz kan ook mits schuine opstelling) gehaald worden. Met

diode ontstaat er een grote release vertragingstijd. Voedingsspanning 183V

dc. Er werd geen noemenswaardige temperatuurstijging genoteerd ook de IGBT

wordt niet warm. Er zijn wel nogal wat bijgeluiden door de primitieve mechanika

van de relaisspoelen zelf.

- 11.03.2009: Bestukking van een puls-only board met een 18F2525 PIC mikrokontroller

en 16 IGBT's. Proeven met VDR's ter onderdrukking van al te hoge spanningspieken

over spoel en IGBT. VDR's met een AC-continuous rating van 150V (of DC 200V)

moeten afdoende zijn. (Gekontroleerd op de skoop).

- 12.03.2009: Positionering van de voedingsonderdelen op de demonteerbare

inox basisplaat. Deze profileerden we terwille van de mechanische sterkte.

Voor inox werd geopteerd omwille van de non ferromagnetische eigenschappen.

Zoniet zouden de transfos kunnen zoemen of brommen.

- 13.02.2009: Levering Farnell van besvestigingsbeugels voor de zware elko's

in de voeding. Konstruktie van de 16 houten hamertjes (2 sets van 4 en 1 set

van 8 hamertjes) uitgaande van relais magneten met IGBT transistorsturing.

Trajektbegrenzingsprofielen voorzien van terugslag-dempingsmateriaal opgelast.

- 14.03.2009: Mechanische konstruktie van het voedingschassis met de vier

transformatoren en de grote elko's. Deze unit kan van het wielstel losgeschroefd

worden mits de robot eerst omhooggetakeld wordt.

- 15.03.2009: Bedrading voedingschassis.

- 16.03.2009: Montage van de set met 8 kloppertjes

- 17.03.2009: Eindmontage voedingsmodule en nameting eigenschappen.

- 18.03.2009: Uittekenen service dokumentatie voor de voeding. Levering Lucas

Ledex rotary solenoids door Newark On Line.

- 19.03.2009: Rotary solenoids zijn geleverd. Ontwerp van een draaimechanisme

met verstelbare kloppers.

- 20.03.2009: Eerste proefmontage met de Lucas Ledex rotary solenoids gemonteerd

op inox steuntjes van 110mm x 30mm x 3mm voorzien van een 12mm montage gat.

De bevestiging van de klopperstang is een nog op te lossen probleem.

- 21.03.2009: 60 gaten 8mm geboord op asafstanden van 100mm in de vertikale

opstanden om montage van allerlei objekten via bevestigingsstukken mogelijk

te maken. Uitzagen bevestigingsplaat voor de bovenste bidirektionele elektromagneet.

- 22.03.2009: TIG laswerk op het bovengedeelte met de bidirektionele elektromagneet.

Bepaling plaatsing van de 16 relaismagneten. Werkongeval: met duim in de slijpmachine

gekneld geraakt... Rechtduimnagel weggeslepen tot op het vlees. Behoorlijk

akelig. Tijdelijk werkonbekwaam.

- 23.03.2009: Voorzichtige poging om toch door te werken met de linkerhand

alleen. TIG lassen op de lastafel blijkt nog aardig goed te lukken. Zagen

kon ik sowieso al met de linkerhand.

- 24.03.2009: Kloppertjes links en rechts op inox driehoek vastgelast aan

hoofdframe. Niet zo triviaal met de linkerhand alleen...

- 25.03.2009: Ontwerp en konstruktie dragers in inox voor de 2 x 3 Laukhuff

magneten, te voorzien van bakelieten kloppertjes. Deze konstruktieelementen

kunnen verstelbaar worden gemonteerd met een M8 bout doorheen het frame. Verstelling

van de hoek die meer dan 15 graden afwijkt van de normale rechtstandigheid

is niet aan te bevelen vanwege de grote slijtage die dit veroorzaakt op de

assen van de magneetankers.(cfr. het euvel in <Troms>)

- 26.03.2009: Ontwerp bevestigingmechanisme voor de snelle opwaartse kloppertjes.

Hiervoor gebruikten we onder andere twee kantelscharnieren afkomstig van oude

pupiters uit het konservatorium. De mechanismen zijn verstelbaar in de uitklaprichting,

vertikaal en kunnen bovendien roteren. Met de armen in gespreide stand ziet

het er net zo belachelijk uit als de jesus salvator beelden die latijns-amerika

zowat overal ontsieren.

- 27.03.2009: Uithonen gaten voor de glijslede van de snelle hamertjes op

de zwenkbare armen. Montage met M8x 80 bouten.

- 28.03.2009: Konstruktie van de hamertjes voor de rotary solenoids, uitgaand

van wieltjes in gietijzer. Het oplassen van inox staafjes en het tappen van

een M3 schroefdraad erdoorheen is tegen alle verwachtingen in goed gelukt.

- 29.03.2009: Montage van de rotary solenoids op het chassis. Elektromechanische

tests.

- 30.03.2009: Bestudering van de optimale plaatsing van de mikroprocessor

boards in het chassis.

- 03.04.2009: Uitsnijden, boren en inlassen van de bevestigingsplaat voor

het IGBT midipuls board met 16 uitgangen. Hierover komt een afscherming in

polykarbonaat.

- 04.04.2009: Bedrading van het kleine midi-puls board en alle relais magneten.

Toevoeging van een 20k ontlaadweerstand in serie met een grote 10mm LED over

de 200V spanning op de voeding. Afwerking en montage van de polykarbonaat

beschermplaat boven het mikroprocessorboard.

- 05.04.2009: Montage van het voedingsblok in het basischassis met 4 lange

M8 bouten. Aansluiting voeding op de hnetingang. Uitsnijden polykarbonaat

beschermingsplaat voor montage boven de voeding middels 4 140mm lange in messing

gezaagde afstandbussen en 4 M8 draadstangen (lengte 200mm). Ontwerp drager

voor het 18F4620 mikroprocessor board.

- 06.04.2009: Afwerking montage 18F4620 board op polykarbonaat plaat. Volledige

bestukking van het 18F4620 board. Begin bedrading van de elektromagneten naar

de processor boards.

- 07.04.2009: Verdere bedrading en aanleg kabelbundels. Draagchassis voor

de pedalen opnieuw losgenomen en afgelakt in donkerblauw. (Zelfde kleur als

het <Trump> chassis.) Ontwerpjes voor 'ogen' met lampjes.

- 08.04.2009: Konstruktie kabelgeleidingen in het onderchassis. Begin uitvoering

lichten: frontlichten en 'ogen'-lichten.

- 09.04.2009: Schilderwerk van alle normaal stalen delen en lasnaden in lichtgrijze

lak. De naden tussen inox en staal moeten niet geschilderd worden, want die

zijn uitgevoerd met roestvrij toevoegmateriaal. Dit diende te gebeuren voor

de uiteindelijke bedrading, want anders kan het chassis niet meer geschilderd

worden.

- 10.04.2009: Inkoop lange M8 inox inbus bouten en sterknoppen met M12 schroefdraad.

Re-assemblage van alle komponenten op het chassis. Bedrading van de lampen.

- 11.04.2009: Bestelling spirawrap bij Conrad.

- 12.04.2009: Dokumentatie bijgewerkt en eerste reeks fotos gemaakt...

- 13.04.2009: Verder werk aan de bedrading van de mechanieken op het onderstel.

- 14.04.2009: Bedrading lichten voorkant. Alle bedrading is nu afgewerkt.

De ontwikkeling van de aansturingskode kan nu beginnen.

- 15.04.2009: Eerste ontwerp van de testkode.

- 16-23.04.2009: Redaktie van een aangepaste kode module binnen GMT.

- 24.04.2009: Finalisatie van de bedrading van de MIDI input signalen.

- 25.04.2009: Ontwikkeling firmware voor de PIC's met Johannes Taelman. Eerste

versies van de firmware geprogrammeerd. Een aantal Mosfets sneuvelden (noten

36,37,41) -wellicht wegens floating gate- bij het eerste inschakelen. Een

van de frontale LED spots is ook meteen gesneuveld: de serieweerstand is gesmolten

en in plaats van de stroom te verbreken, smolt hij tot een nul-ohm verbinding...

- 26.04.2009: Het kleine PIC board (18F2525) wordt aan foltertests onderworpen.

De voedingsspanning voor de relais-magneten zakt bij volle belasting van 208V

tot 192V, wat een goed rezultaat is. Een spoel heeft wat last van remanent

magnetisme. De opwarming van de spoelen is gering. Beide PIC's kunnen nu met

dezelfde pinkode van lookup tables voor de velocities voorzien worden. De

pincode is 'hat '. De spatie na de t is absoluut noodzakelijk! Elektrische

tests blijken in orde te zijn, na vervanging van de drie gesneuvelde mosfets.

- 27.04.2009: Hat trommelt erop los... De testkode is nu helemaal van alle

bugs ontdaan.

- 28.04.2009: specifikatie en bestelling lampjes voor de voorkant.

- 29-30.04.2009: Konstruktie van houders voor test slagobjekten.

- 02.05.2009: Montage dempertjes en kussentjes onder de achterste magneten.

- 03-06.2009: Tests met diverse objekten. Wegwerken bugs in de besturingskode.

Uitmeten van de aanslagtrajekten. Interview voor Studio Brussel over de <Hat>

robot.

- 08.05.2009: Test en besturingskode overgebracht naar Windows 7 op mijn nieuwste

quad-processor PC...

- 09-13.05.2009: Verdere ontwikkeling testkode en bevestigingssystemen.

- 17.05.2009: TIG-laswerk stuurbeugel uit 25mm diameter inox buis en lasbochten.

Montage vooruitstekend onder een hoek van 60 graden. Het hele stuur kan worden

weggenomen en is gemonteerd met twee inox M12 schroefdraden die passen in

de vork van het voorwiel.

- 18.05.2009: Uitsnijden ronde PTFE plaat (Teflon), diameter 160mm, dikte

3mm, asgat 20mm als lager voor het horizontaal draaiende deel van het voorwiel.

- 19.05.2009: Uitzoeken in katalogi en bestellen van klem en bevestigingsmateriaal

voor slagobjekten.

- 20.05.2009: Afwerking mechanika vingertjes: 8 M3 boutjes uitgeboord op de

draaibank met een centraal gat van 1.5mm zodat we bakeliet M3 kogelkoppen

kunnen monteren als kloppertjes. Fixatie met polyacrylaat lijm. Inkleven 5mm

dikke viltjes onderaan ter demping van de terugval van de ankertjes.

- 22.05.2009: De bestelde chemie-laboratorium klemmen en verbindingsstukken

besteld bij Farnell zijn geleverd.

- 23.05.2009: Experimenten met perkussieve montage objekten.

- 27.05.2009: Verdere konstruktie montagehulpstukken.

- 28.05.2009-11.06.2009: Werkpauze, vanwege teveel ander dringend werk en

examens af te nemen...

- 01.08.2009: Work on <Hat> taken up again. Backside tambourine mounted

for test.

- 02.08.2009: The ordered LED lites for the front have still not yet arrived...

Further mounting works.

- 03.08.2009: Attachment rods cut and welded together for side objects. For

test, we mounted another couple of sheepskin tambourines.

- 04.08.2009: Brass shim mounted to serve as thundersheet. More attachment

rods welded and mounted on the structure. Frontlite bulbs reordered, from

Conrad this time...

- 05.08.2009: Mounting of a large 35mm filmcan as a possible 'anything' in

the left bassdrum pedal holder. Woodblock mounted over right hand. Finishing

mounting of the frontwheel axle with circlips. Lathe work for the slots.

- 06.08.2009: Test runs with objects attached. Front lites delivered and mounted

immediately. Test code adapted for optimizing velocity scalings. Progress

reported to Richard James.

- 07.08.2009: Construction of the polycarbonate protection plate for the 18F4650

microprocessor board. Bakelite beaters on the left hand mechanism glued with

cyanacrylate glue. Yvan Vander Sanden works on a demo piece for <Hat>.

- 01.10.2009: Both Yvan Vander Sanden and Kristof Lauwers are preparing a

demo piece for <Hat>. Should be ready for the upcoming M&M concert

on october 15th at logos.

- 02.10.2009: Sysex velocity scalings uploaded by Kristof Lauwers.

- 06.10.2009: Further work on the sysex'es by Kristof. Troy Rogers is also

considering a piece for <Hat> now.

- 13.10.2009: Yvan Vander Sanden finished a piece for <Hat> and the

robot orchestra, Kristof Lauwers and Troy Rogers have a piece for <Hat>

as well.

- 15.10.1009: <Hat> presented on the 'Kreatie' concert with the M&M

robot orchestra.

- 04.11.2009: Final organisation of the shipping of the <Hat> robot

to the UK...

- 05.11.2009: Finalisation of a user friendly interface for the sysex dumps

to the <Hat> robot by Kristof Lauwers.

- 12.11.2009: Organisation of the transport of the robot to Cornwall. This

will be by Yvan Vander Sanden and Troy Rogers.

- 19.11.2009: Further refinements on the velocity scaling of the pedal mechanisms.

Replacement of return springs with slightly softer types, more adapted to

robotic action.

- 04.12.2009: Kristof's composition for Hat recorded for CD.

- 08.12.2009: video documentation made by Yvan Vander Sanden.

- 09.12.2009: finalisation of sysex code by Kristof Lauwers. Last fixes of

mechanical issues: wheels secured with splitpens, bounceback dampers fitted

to the rotary solenoids. Redaction of the users manual. Robot weighted: 94kg.

Builder name plate in brass mounted, engraved 'me fecit logos'.

- 10.12.2009: assembly of a mounting kit. We even provide a british mains

cord and plug...

- 11.12.2009: Delivery trip to the UK with Hat, up to Aphex Twin. Two drivers:

Troy Rogers and Yvan Vander Sanden.

On the picture: Yvan Vander Sanden and Aphex Twin figuring out how to get

<Hat> into the barn.

On the picture: Yvan Vander Sanden and Aphex Twin figuring out how to get

<Hat> into the barn.

- 14.12.2009: Yvan and Troy returned safely from Cornwall. <Hat> is

delivered.

- 05.08.2010: Two pieces for <Hat> released on our 'Lonely Robots' CD,

LPD019.

- 24.04.2020: <Hat> tested on its return from Cornwall. No failures

observed.

- 21-22-23.07.2020: <Hat> plays an important role in our 'Noli me tangere'

production with dancer Emilie De Vlam.

- 24.07.2020: Mounting of the upper shaker magnet repaired: the bolts came

loose during the headshakes performed.

- 27.07.2021: <Hat> used with a small bass drum and a tiny snare drum

by Alain Van Zeveren. He also used it in his composition for the robot orchestra,

streamed in february.

Last update: 2023-01-19

by Godfried-Willem Raes

Techical drawings construction:

Frontwheel welding diagram

Backside, photo-sketch:

Technical data sheet and maintenance instructions:

- Frontwheel: diameter 380mm, axe: 25mm, axe depth: 90mm. Forkspan: 100mm.

Massive tire.

- Backwheels: diameter 250mm, axe: 25mm, axe depth: 65mm. Massive tires. (Bickle)

- Brake: M10 thread, stainless steel.

- Steel profiles used in the construction:

- rectangular tube 180 x 80 x 5, ST42

- square tube: 50 x 50 x 4, ST42

- L- profile: 50 x 50 x 5, ST42

- flat: 100 x 10, ST42

- flat: 50 x 5, ST42

- massive rod: 25mm, hardened steel, ST54

- massive rod: 12mm, stainless steel AISI 316

- flat 50 x 5, AISI 304L

- stainless steel plate, 1 mm thickness

- stainless steel plate, 2 mm thickness

- stainless steel plate, 3 mm thickness

- AISI316 stainless steel tube 25 mm x 2

- AISI316 stanless steel tube 50 mm x 2

- AISI304 stainless steel square tube 50 x 50 x 2

- flat 50 x 10, AISI 304L

- L-profile 20 x 20 x 3, stainless steel AISI304L

- flat 30 x 3, AISI 304L

- 4 stainless steel flanges 48mm x 2mm

Power Supply circuit:

Note that the power supply carries dangerous voltages. Before servicing, switch

off the robot and give it 10 minutes rest, to enable the hefty capacitors to

discharge. The connections on the power supply module are laid out as follows:

Electromechanical parts:

finger solenoids, Marked BLP 44A 220 621 620, 8 MO213, Farnell order code 1207167,

12V @ 100% duty cycle. DC resistance 47 Ohm. Power rating: 3 Watt.  Push type. Plunger weigth: 8.5g. Stroke: 12mm maximum. When operated on 24V,

we obtain a power of 12W but duty cycle should be limited to 25%. Maximum current

during the pulse than becomes 510mA. All threads for mounting are M3. Website

of the manufacturer: http://www.blpcomp.com. (eight pieces used)

Push type. Plunger weigth: 8.5g. Stroke: 12mm maximum. When operated on 24V,

we obtain a power of 12W but duty cycle should be limited to 25%. Maximum current

during the pulse than becomes 510mA. All threads for mounting are M3. Website

of the manufacturer: http://www.blpcomp.com. (eight pieces used)

beater solenoids: Black Knight,  12 V @ 100% duty cycle.

12 V @ 100% duty cycle.

Pedal solenoids: August Laukhuff, 24 V, 1.4 A @ 100% Duty cycle for 75 N force,

travel 20 mm. Rdc = 17 Ohm. Laukhuff order number: 301010 (two pieces used)

Sideways solenoids: Laukhuff Tonventilmagnet 12/14V, Rdc = 30 Ohm, 470 mA,

6 to 7.5 N force at duty cycle 100%. Laukhuff order number: 300900. (six pieces

used)

Rotary solenoids: Lucas Ledex (now Saaia Burgess) type H-2711-033. Axle 4.7mm,

device diameter: 35mm. Rotation angle: 45 degrees. These solenoids are extremely

expensive! (two pieces used) If they need replacement, it would be better to

use type L-2711-033(CW) and L-2712-033 (CCW). DC resistance: 75,3 Ohms, nominal

100% duty cycle voltage: 26V, at 50% duty: 37V, at 25% duty, 53V, at 10% duty

83V and at 5% duty cycle 118V.

Lights:

Top-lites: Paulmann, LED 50mm spotlights, 12V 1W. Beam angle: 24 degrees. Lifetime

50000h. Socket GU5.3 Light color temperature 6400-7000K (daylight).

Frontwheel-lites: LED 50mm spotlights, 12V 1W, Beam angle: 15 degrees. Socket

GU5.3 - MR16. Lifetime 50000h. 240 Lux. Conrad order number: 570949.

Never replace these lights with different types! The lites are fixed in the

flanges with silicone glue. They can only be removed with a sharp knive or a

chivel. Before doing this, make sure the robot is unplugged and has been given

enough time for the capacitors to fully discharge.

with some 'anythings' mounted:

with some 'anythings' mounted:

Deze

elektromagneten zijn voorzien van een veer om de terugslag nog te versnellen.

Deze

elektromagneten zijn voorzien van een veer om de terugslag nog te versnellen.

De overbrengingsketting is met een gehard M3 boutje (lengte 20mm) doorheen

de inox lange busmoer vastgezet. Door verdraaing van het anker van de elektromagneet

tegenover de busmoer kan het aanslagpunt van de klopper precies worden ingesteld

en afgeregeld. Funktionele mechanische en elektrische tests van het mechanisme.

De overbrengingsketting is met een gehard M3 boutje (lengte 20mm) doorheen

de inox lange busmoer vastgezet. Door verdraaing van het anker van de elektromagneet

tegenover de busmoer kan het aanslagpunt van de klopper precies worden ingesteld

en afgeregeld. Funktionele mechanische en elektrische tests van het mechanisme. Het eerste ontwikkelde type is voorzien van een relatief zware houten kogel.

Dit werkt maar levert dubbele aanslagen op vanwege de veerkracht van de beide

staafjes waarmee de kogel is bevestigd.

Het eerste ontwikkelde type is voorzien van een relatief zware houten kogel.

Dit werkt maar levert dubbele aanslagen op vanwege de veerkracht van de beide

staafjes waarmee de kogel is bevestigd.

In het tweede proefprojekt

gebruikten we lastoevoegmateriaal van 2.4 mm diameter waarop we kleine houten

langgerokken kogels monteerden.

In het tweede proefprojekt

gebruikten we lastoevoegmateriaal van 2.4 mm diameter waarop we kleine houten

langgerokken kogels monteerden.

On the picture: Yvan Vander Sanden and Aphex Twin figuring out how to get

<Hat> into the barn.

On the picture: Yvan Vander Sanden and Aphex Twin figuring out how to get

<Hat> into the barn.

Push type. Plunger weigth: 8.5g. Stroke: 12mm maximum. When operated on 24V,

we obtain a power of 12W but duty cycle should be limited to 25%. Maximum current

during the pulse than becomes 510mA. All threads for mounting are M3. Website

of the manufacturer: http://www.blpcomp.com. (eight pieces used)

Push type. Plunger weigth: 8.5g. Stroke: 12mm maximum. When operated on 24V,

we obtain a power of 12W but duty cycle should be limited to 25%. Maximum current

during the pulse than becomes 510mA. All threads for mounting are M3. Website

of the manufacturer: http://www.blpcomp.com. (eight pieces used) 12 V @ 100% duty cycle.

12 V @ 100% duty cycle.