Expression control in automated organs and its perspectives for preservation of the past

a paper presented at the SCAD conference, 17.02.2011

Prof.dr.Godfried-Willem Raes

postdoctoral researcher

Ghent University College & Logos Foundation

2011

Expression control in automated organs and its perspectives for preservation of the past

a paper presented at the SCAD conference, 17.02.2011

Prof.dr.Godfried-Willem Raes

postdoctoral researcher

Ghent University College & Logos Foundation

2011

The practice of automating musical instruments is in no way recent, and in fact might very well be about just as old as the history of that class of musical instruments where many mechanical parts, levers, wheels, bellows, hammers are used to control the actual sound sources. We all know the watchmakers and their skills in the construction of musical clocks. On a very large scale -the principles being the same- we can also refer to the vast tradition of carilons on our belfry and some church towers. Before the advent of electronic circuitry, musical automata, orchestrions and barrel organs were built using mechanical or pneumatic principles. Up to the 19th century, the pinned barrel was the device of choice to program the music into the automaton. With the 19th century came the advent of pneumatic principles. All the automatic instruments made at that time (the antique Limonaire organs, Pianolas, Mortier organs, Decaps and many more) use paper rolls or cardboard books for programming and are pneumatic. In nature they are, just like their purely mechanical ancestors, binary machines: a punched hole in the roll is a note-on, no hole is a note-off. Musical expression - apart from the precise placement of tones in time, or overall control of the wind pressure - is left out altogether from these designs which is what explains the very mechanical character of the music produced. Although it is not impossible to implement gradual and nuanced control using pneumatic technology (and many attempts to do so have been made, sometimes with reasonable results), it is only since the advent of electromechanical or electropneumatic devices and particularly microcontrollers that this has become common practice amongst modern automated instrument builders. Instrument automation has been keeping us busy since the early 1970s, and in this paper we will concentrate on some aspects of expression control applied to organ building. We will try to give a broad overview of technologies and approaches applicable to organ-type musical automates with expressive possibilities way beyond the simple, if by no means trivial, note-on, note-off that has plagued automata for way too long. All the aforesaid technologies described here have been put into practice in one or another of the 46 musical robots -not all organs of course- that currently make up the <M&M> robot orchestra.

The first organ building project we undertook started off one day rather by accident. Eldermen from the protestant church in the Brabantdam in Ghent decided to get rid of the 18th century organ in their church, since the costs for real restauration was outrageous. They happened to know us as an instrument builder and offered us to buy it for the symbolic sum of 100 Euro. So I did and here I was with the remnants of a complete organ... Most of the wood pipes were either eaten by worms or severely attacked by moulds. The lead pipes had been stacked horizontally for many years and thus we found all almost completely smashed. Only the vox humana register, with its short resonators and thick pipefeet at first looked more or less o.k. When opening these pipes however, we noticed the disaster caused by tin pest: all parts where covered with a thick layer of lead oxide. After a tedious restauration session on this register, we got all the pipes to speak again and we took up the idea to automate it. <Vox Humanola> was about to be born.

The wind is generated by a Laukhuff

radial compressor, controlled with an electronic motor controller such that

wind pressure can be brought under precise computer control. As in these early

designs, we copied most elements from traditional organs, we provided in bellows,

believing they were required for wind stabilisation. Later we discovered that

we can easily go without bellows, as long the motol control is well designed

as an autoregulating system. The windchest, made in steel, is populated with

direct acting solenoid valves with varying orifices. These industrial valves

required some modification to make them suitable for use in a musical instrument:

the action was noisy. To suppress the clicking noise, we cut of a slice of the

ferromagnetic anchors and glued a round piece of felt in place. The solenoid

valves could now be switched under computer control. We finally succeeded in

making this register sound in all its glory again.

The wind is generated by a Laukhuff

radial compressor, controlled with an electronic motor controller such that

wind pressure can be brought under precise computer control. As in these early

designs, we copied most elements from traditional organs, we provided in bellows,

believing they were required for wind stabilisation. Later we discovered that

we can easily go without bellows, as long the motol control is well designed

as an autoregulating system. The windchest, made in steel, is populated with

direct acting solenoid valves with varying orifices. These industrial valves

required some modification to make them suitable for use in a musical instrument:

the action was noisy. To suppress the clicking noise, we cut of a slice of the

ferromagnetic anchors and glued a round piece of felt in place. The solenoid

valves could now be switched under computer control. We finally succeeded in

making this register sound in all its glory again.

The second register we recycled consisted of small lead pipes and was made

into our <Piperola> robot, along similar lines. Here we added a nice pressure

tremulant, working on the bellows.

The last automate we

derived from this same 18th century organ became <Trump>. In this case,

taking anto account the completely ruined state of all resonator on the trumpet

pipework, we decided to design something more original. We modified the scaling

of the register such that we would obtain a gradual shifting formant over the

compass of the instrument. To homogenize the sound output, we placed all pipes

in an exponential horn. Here we did not use any form of bellows anymore, neither

did we used industrial solenoid valves. Instead, here we applied flat pallet

valves mounted inside the windchest.

The last automate we

derived from this same 18th century organ became <Trump>. In this case,

taking anto account the completely ruined state of all resonator on the trumpet

pipework, we decided to design something more original. We modified the scaling

of the register such that we would obtain a gradual shifting formant over the

compass of the instrument. To homogenize the sound output, we placed all pipes

in an exponential horn. Here we did not use any form of bellows anymore, neither

did we used industrial solenoid valves. Instead, here we applied flat pallet

valves mounted inside the windchest.

One day, we gor an offer for a bunch of wooden open organ pipes made by Oscar

Van Peteghem. They looked restaurable and only 4 pipes needed to be remade in

order to make a reasonable automate. This became <Bourdonola>:  The pipes were modified by us later, to yield a more string like sound, by placing

harmonic bridges over the flues of the pipes.

The pipes were modified by us later, to yield a more string like sound, by placing

harmonic bridges over the flues of the pipes.

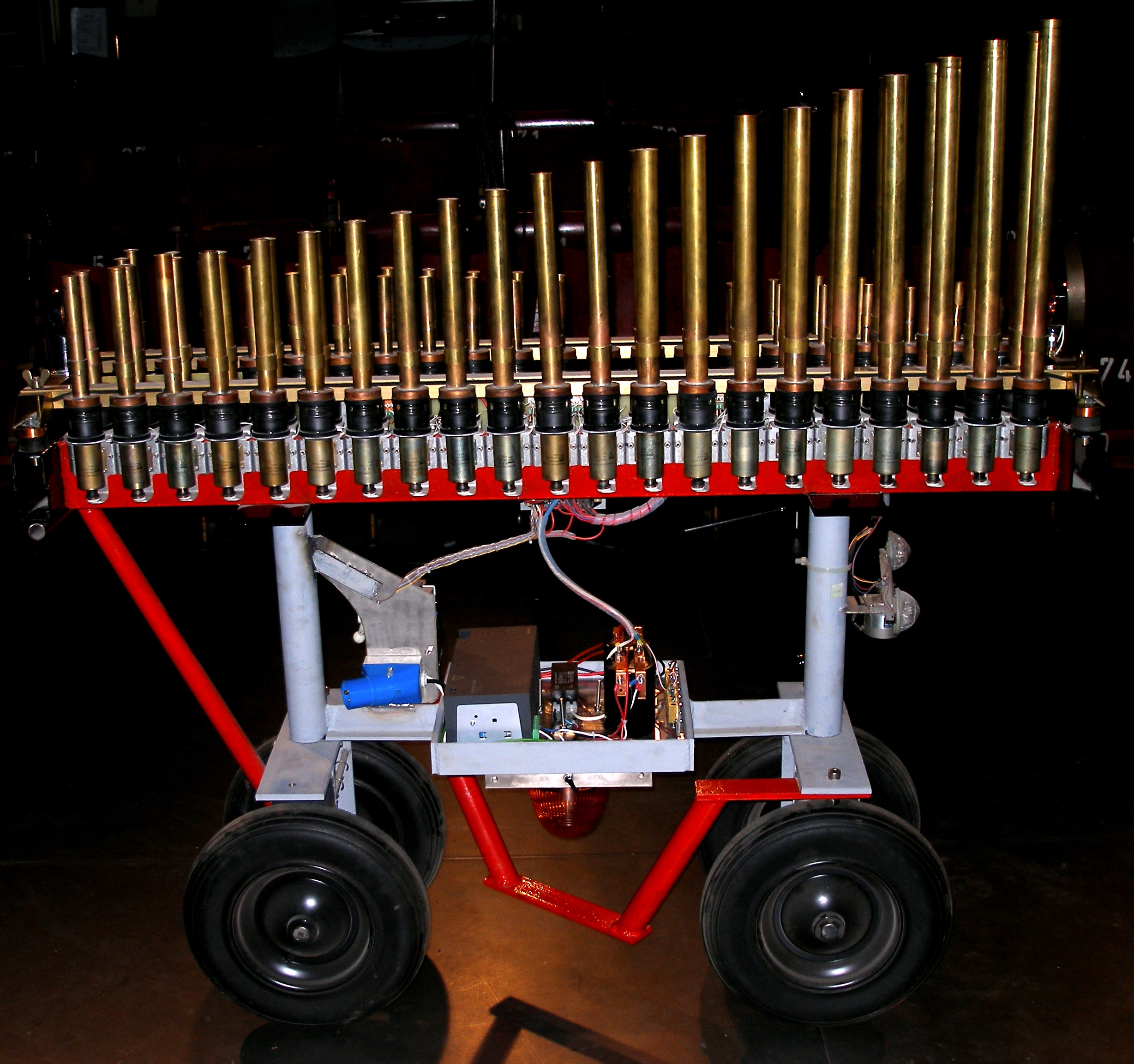

It became about time for a more adventurous untertaking: what about a percussive

organ, where each pipe would get its wind from its own bellows? This was the

idea behind <Puff>, sounding more or less like a system of pan flutes.

Moreover, this was the first organ module we designed with equal temperament

quartertone tuning. All pipes where made of hardened brass in the style of ordinary

penny whistles and can be overblown if enough wind pressure is generated. The individual bellows are made from pyrex glass cylinders with a well fitting

plunger from carbon compound. The plunger is set into motion under the action

of a push type solenoid. By changing the pulse time of the applied voltage to

the solenoids we obtain very precise control over the dynamic of the pipes.

Responsiveness is excellent and speed astonishing. Here is a detail of the air

pumps, the driving solenoids and the speaking pipes:

The individual bellows are made from pyrex glass cylinders with a well fitting

plunger from carbon compound. The plunger is set into motion under the action

of a push type solenoid. By changing the pulse time of the applied voltage to

the solenoids we obtain very precise control over the dynamic of the pipes.

Responsiveness is excellent and speed astonishing. Here is a detail of the air

pumps, the driving solenoids and the speaking pipes:

A wooden cromorno register, newly made, lead us to the design and construction

of the <Krum> robot: The

pipes use brass tongues on wooden shallots. The wind in this module can be controlled

via the motorcontroller -inherently slow because of the inertia of the propeller-

or, by a large regulating valve using a bidirectional solenoid placed on the

wind inlet of the compressor. The result came out to be extremely compact and

transportable. The wind modulation scheme was not veryu succesfull because the

pipes do not keep tuning very well under varying wind pressure conditions.

The

pipes use brass tongues on wooden shallots. The wind in this module can be controlled

via the motorcontroller -inherently slow because of the inertia of the propeller-

or, by a large regulating valve using a bidirectional solenoid placed on the

wind inlet of the compressor. The result came out to be extremely compact and

transportable. The wind modulation scheme was not veryu succesfull because the

pipes do not keep tuning very well under varying wind pressure conditions.

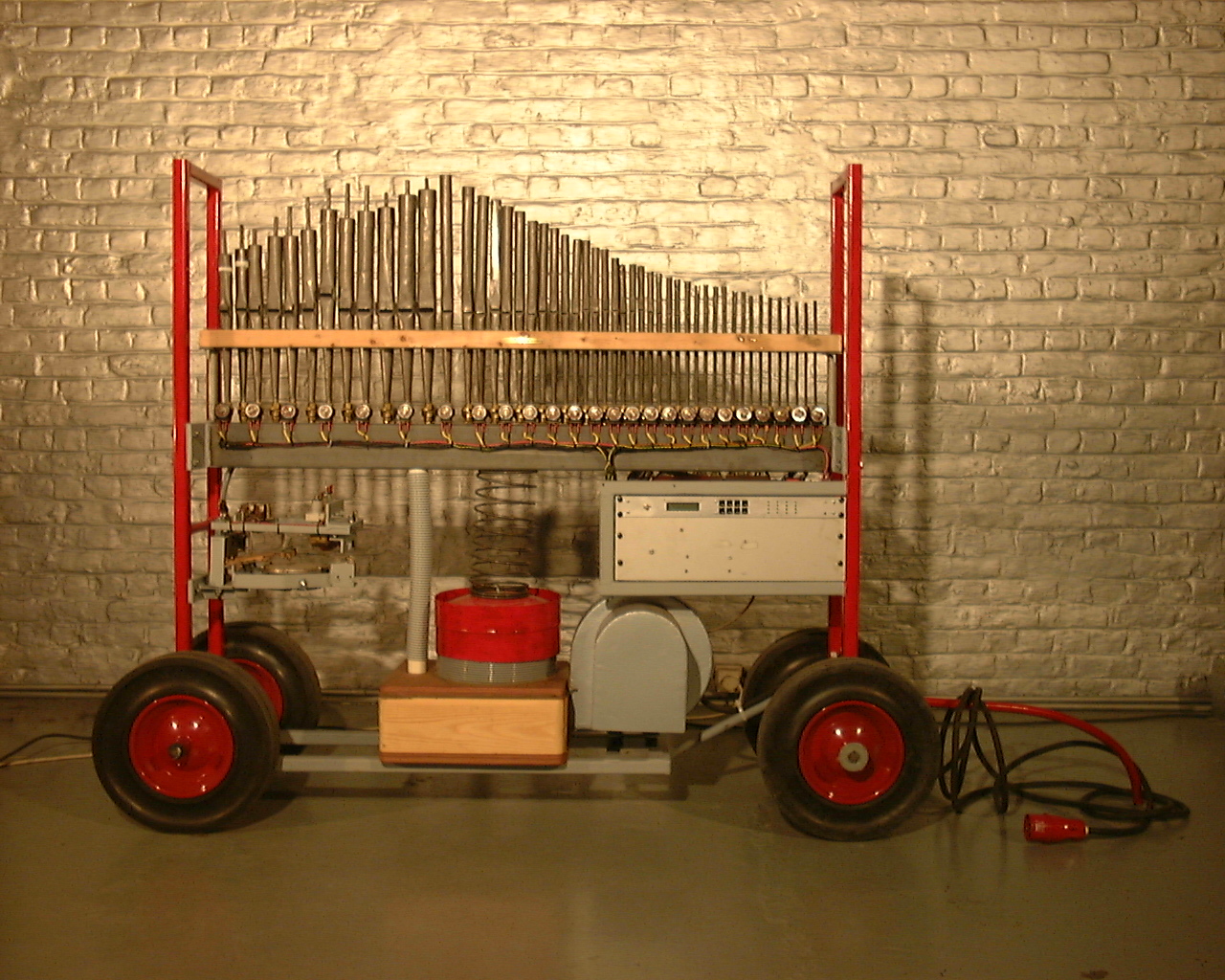

In 1997 we suceeded in getting a research project accepted, to design and build

a completely new module: a quartertone organ with a compass of six octaves using

metal pipework and closed pipes. The <Qt> organ robot was build in collaboration

with Ghuislain Potvlieghe and Johannes Taelman. In this design we applied velocity

sensitivity for all individual notes for the first time. Note aftertouch was

also implemented, but not yet in an optimal way, as we learned later on.  With its 145 pipes, <Qt> could barely become a light instrument. Although

it weigths over 270 kg, it is easily transportable using its own sturdy and

flexible wheelbase.

With its 145 pipes, <Qt> could barely become a light instrument. Although

it weigths over 270 kg, it is easily transportable using its own sturdy and

flexible wheelbase.

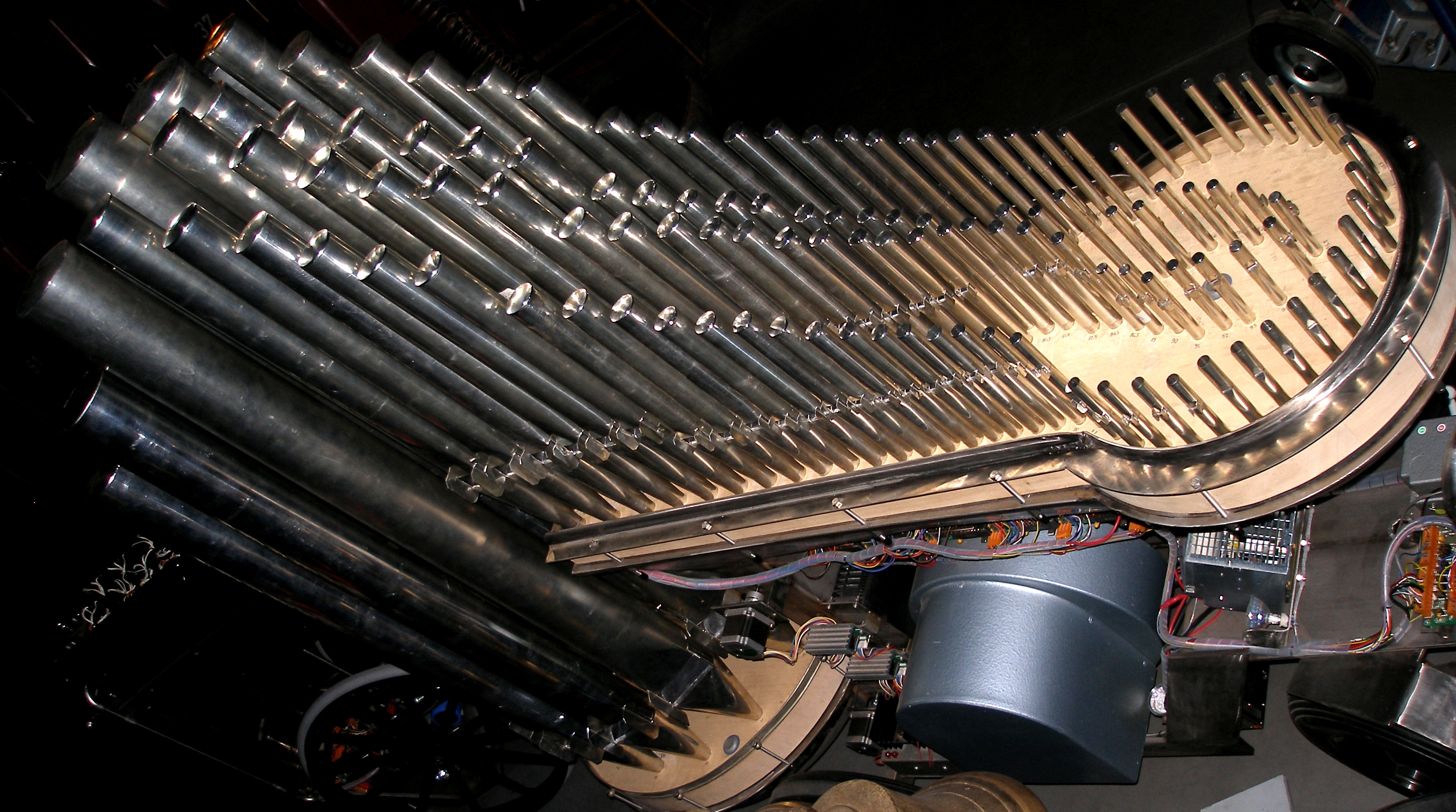

The most recent organ automate we finished in 2010, was <Bomi>. The purpose

here was to go into the extremes of what can be obtained in expression control

using otherwize traditional pipework. Through the systematic use of conical

valves driven by solenoids in the windchest, we not only could implement attack

controll, but also individual note aftertouch and modulation for each pipe.

A very flexible and responsive tremulant valve, again realized using a conical

valve, can be used not only as a tremulant but also as a very fast responding

wind pressure modulation device. The musical possibilities easily surpass anything possible in any traditional

organ design we know of and this module was in fact used at many occasions for

performances of ancient music, where it can easily cope with the most musically

sensitive recorder or flute parts.

The musical possibilities easily surpass anything possible in any traditional

organ design we know of and this module was in fact used at many occasions for

performances of ancient music, where it can easily cope with the most musically

sensitive recorder or flute parts.

Although our main concern in instrument building is into the extension of expressive possibilities in musical automatons, a need in the field of contemporary music, we believe strongly that the perspectives of application of technologies developed here, are extremely relevant even when it comes to valorisation and preservation of dead historical organs for which the complete reconstruction is not an option. Almost all churches have or used to have a pipe organ. By far not all of these instruments have characteristics that can legitimate their preservation, let alone their restoration. And even, if they have the required characteristics, it may not be a very rational nor economic decision to invest the considerable funds into the restoration because the use of the instruments can in no way be guaranteed. The future of churches as churches being far from evident.

For those churches that serve a function as monument and that do attract visitors, it is becomes a realistic option to reconstruct the essential parts of the organ -register by register- using the technologies described here such that the sound of the instrument can be heard whenever required. We stress the fact that automating such instruments is fully reversible at the one hand and at the other, does not render normal manual playing impossible.

Last revision: February 15, 2011